B | A |

|

| B |

|

|

| ||

|

|

|

| |

Shadow |

|

|

| |

Tray |

|

|

|

|

| C |

|

|

|

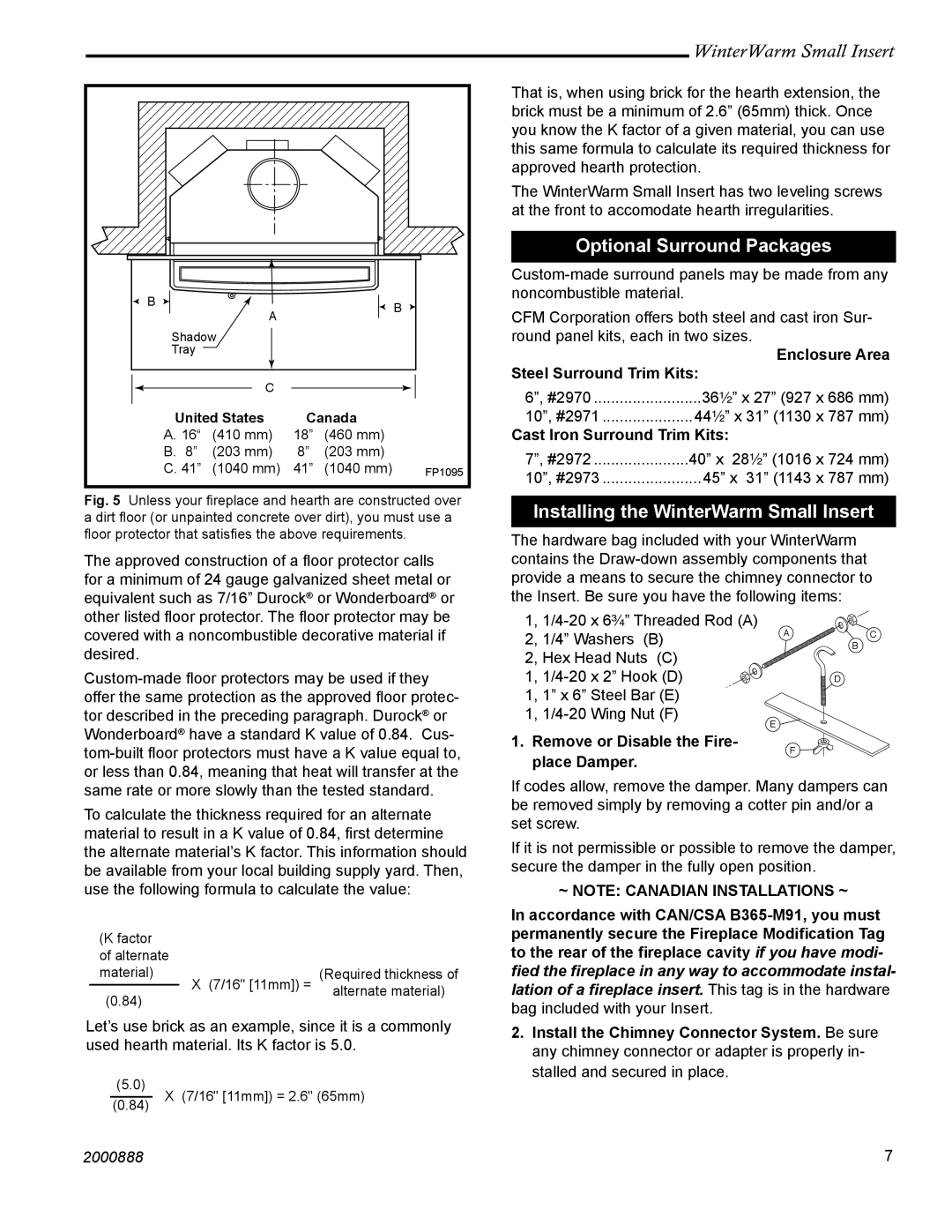

United States | Canada |

| ||

A. 16“ | (410 mm) | 18” | (460 mm) |

|

B. 8” | (203 mm) | 8” | (203 mm) |

|

C. 41” | (1040 mm) | 41” | (1040 mm) | FP1095 |

Fig. 5 Unless your fireplace and hearth are constructed over a dirt floor (or unpainted concrete over dirt), you must use a floor protector that satisfies the above requirements.

The approved construction of a floor protector calls for a minimum of 24 gauge galvanized sheet metal or equivalent such as 7/16” Durock® or Wonderboard® or

WinterWarm Small Insert

That is, when using brick for the hearth extension, the brick must be a minimum of 2.6” (65mm) thick. Once you know the K factor of a given material, you can use this same formula to calculate its required thickness for approved hearth protection.

The WinterWarm Small Insert has two leveling screws at the front to accomodate hearth irregularities.

Optional Surround Packages

CFM Corporation offers both steel and cast iron Sur- round panel kits, each in two sizes.

| Enclosure Area |

Steel Surround Trim Kits: | |

6”, #2970 | 36¹⁄₂” x 27” (927 x 686 mm) |

10”, #2971 | 44¹⁄₂” x 31” (1130 x 787 mm) |

Cast Iron Surround Trim Kits: | |

7”, #2972 | 40” x 28¹⁄₂” (1016 x 724 mm) |

10”, #2973 | 45” x 31” (1143 x 787 mm) |

Installing the WinterWarm Small Insert

The hardware bag included with your WinterWarm contains the

other listed floor protector. The floor protector may be covered with a noncombustible decorative material if desired.

1,

2, Hex Head Nuts (C)

1,

1,

1.Remove or Disable the Fire- place Damper.

A ![]()

![]()

![]()

![]()

![]() C

C ![]()

![]()

![]() B

B

D

E

F

same rate or more slowly than the tested standard.

To calculate the thickness required for an alternate material to result in a K value of 0.84, first determine the alternate material’s K factor. This information should be available from your local building supply yard. Then, use the following formula to calculate the value:

(K factor |

| ||

of alternate |

| ||

material) | (Required thickness of | ||

| X (7/16" [11mm]) = | ||

(0.84) | alternate material) | ||

| |||

|

| ||

Let’s use brick as an example, since it is a commonly used hearth material. Its K factor is 5.0.

(5.0) | X (7/16" [11mm]) = 2.6" (65mm) | |

| ||

(0.84) | ||

|

If codes allow, remove the damper. Many dampers can be removed simply by removing a cotter pin and/or a set screw.

If it is not permissible or possible to remove the damper, secure the damper in the fully open position.

~ NOTE: CANADIAN INSTALLATIONS ~

In accordance with CAN/CSA

2.Install the Chimney Connector System. Be sure any chimney connector or adapter is properly in- stalled and secured in place.

2000888 | 7 |