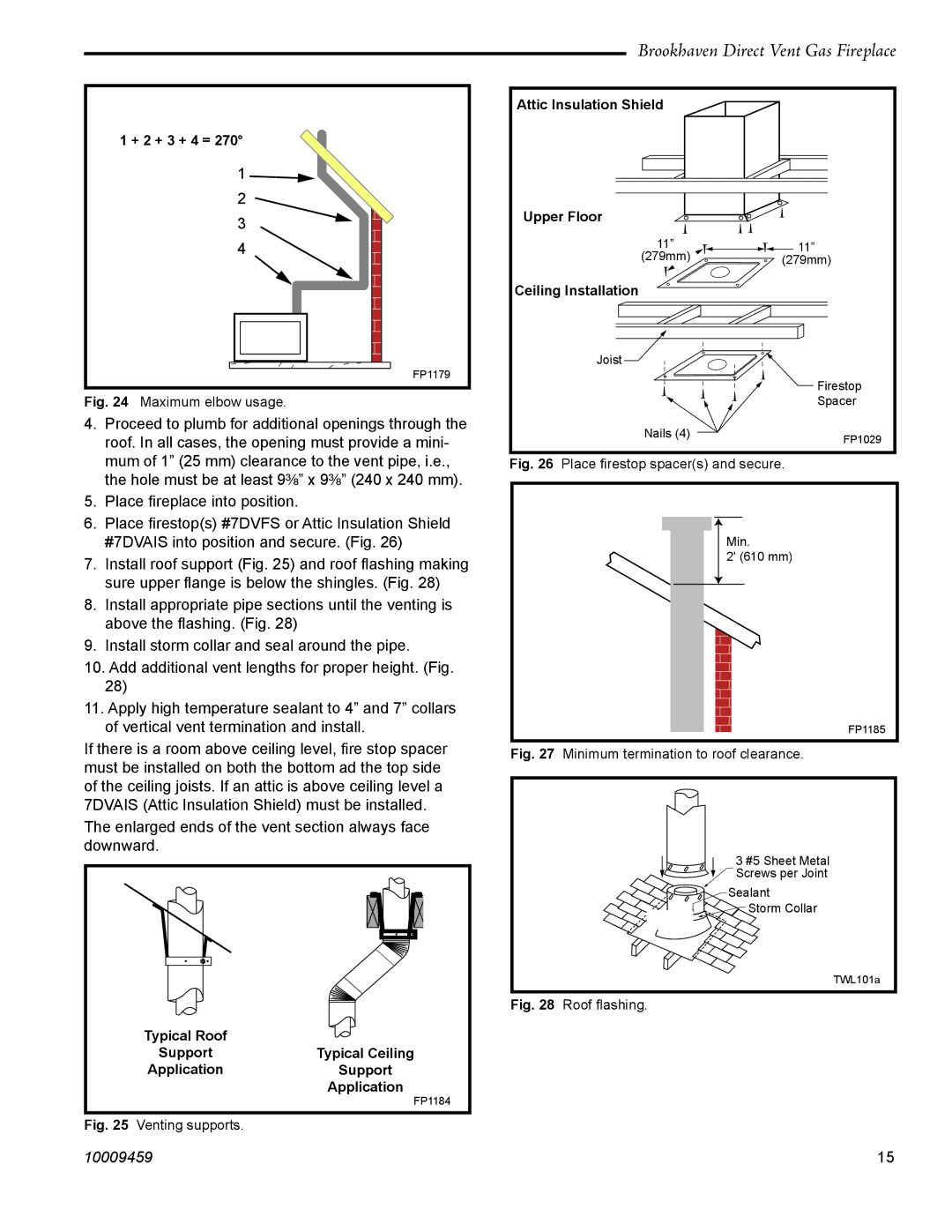

1 + 2 + 3 + 4 = 270°

1 ![]()

2

3

4

FP1179

Fig. 24 Maximum elbow usage.

4.Proceed to plumb for additional openings through the roof. In all cases, the opening must provide a mini- mum of 1” (25 mm) clearance to the vent pipe, i.e., the hole must be at least 9³⁄₈” x 9³⁄₈” (240 x 240 mm).

5.Place fireplace into position.

6.Place firestop(s) #7DVFS or Attic Insulation Shield #7DVAIS into position and secure. (Fig. 26)

7.Install roof support (Fig. 25) and roof flashing making sure upper flange is below the shingles. (Fig. 28)

8.Install appropriate pipe sections until the venting is above the flashing. (Fig. 28)

9.Install storm collar and seal around the pipe.

10.Add additional vent lengths for proper height. (Fig. 28)

11.Apply high temperature sealant to 4” and 7” collars of vertical vent termination and install.

If there is a room above ceiling level, fire stop spacer must be installed on both the bottom ad the top side of the ceiling joists. If an attic is above ceiling level a 7DVAIS (Attic Insulation Shield) must be installed.

The enlarged ends of the vent section always face downward.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Typical Roof |

|

|

|

|

| ||

|

|

|

|

| |||

Support | Typical Ceiling | ||||||

Application |

| Support | |||||

|

|

| Application | ||||

|

|

|

|

|

|

| FP1184 |

|

|

|

|

|

|

|

|

Fig. 25 Venting supports. |

|

|

|

|

| ||

Brookhaven Direct Vent Gas Fireplace

Attic Insulation Shield

Upper Floor

11” | 11” | |

(279mm) | ||

(279mm) | ||

|

Ceiling Installation

Joist |

|

| Firestop |

| Spacer |

Nails (4) | FP1029 |

|

Fig. 26 Place firestop spacer(s) and secure.

Min.

2' (610 mm)

FP1185

Fig. 27 Minimum termination to roof clearance.

3 #5 Sheet Metal

![]()

![]()

![]() Screws per Joint

Screws per Joint

Sealant

![]()

![]() Storm Collar

Storm Collar

TWL101a

Fig. 28 Roof flashing.

10009459 | 15 |