Brookhaven Direct Vent Gas Fireplace

Framing and Finishing

Check fireplace to make sure it is levelled and properly positioned.

To mount the appliance:

1.Choose the location.

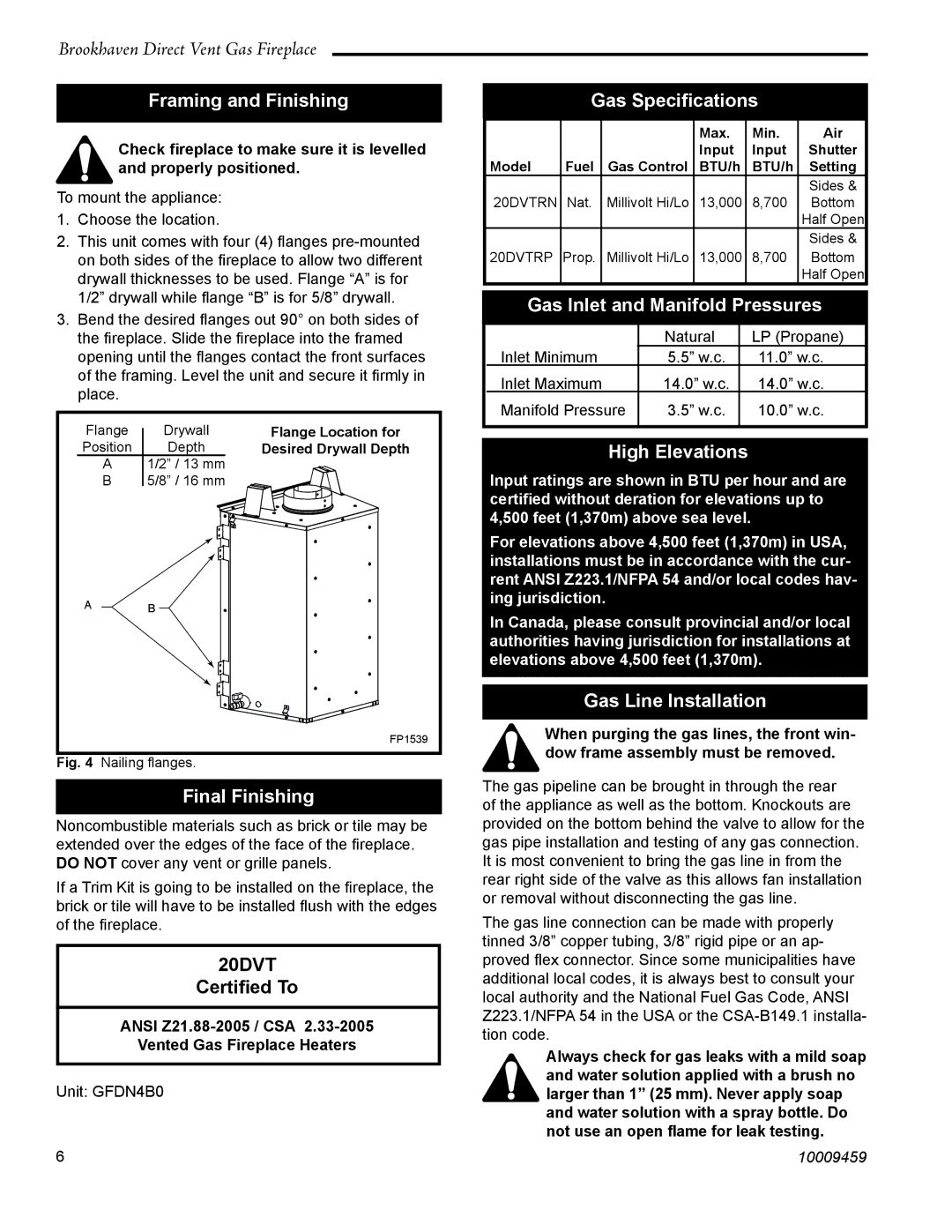

2.This unit comes with four (4) flanges

3.Bend the desired flanges out 90° on both sides of the fireplace. Slide the fireplace into the framed opening until the flanges contact the front surfaces of the framing. Level the unit and secure it firmly in place.

Flange | Drywall | Flange Location for |

Position | Depth | Desired Drywall Depth |

A | 1/2” / 13 mm |

|

B | 5/8” / 16 mm |

|

AB

FP1539

Fig. 4 Nailing flanges.

Final Finishing

Noncombustible materials such as brick or tile may be extended over the edges of the face of the fireplace. DO NOT cover any vent or grille panels.

If a Trim Kit is going to be installed on the fireplace, the brick or tile will have to be installed flush with the edges of the fireplace.

20DVT

Certified To

ANSI

Vented Gas Fireplace Heaters

Unit: GFDN4B0

Gas Specifications

|

|

|

|

| Max. | Min. | Air | |

|

|

|

|

| Input | Input | Shutter | |

Model | Fuel | Gas Control | BTU/h | BTU/h | Setting | |||

|

|

|

|

|

|

|

| Sides & |

20DVTRN | Nat. | Millivolt Hi/Lo | 13,000 | 8,700 | Bottom | |||

|

|

|

|

|

|

|

| Half Open |

|

|

|

|

|

|

|

| Sides & |

20DVTRP | Prop. | Millivolt Hi/Lo | 13,000 | 8,700 | Bottom | |||

|

|

|

|

|

|

|

| Half Open |

|

|

|

|

|

|

|

|

|

Gas Inlet and Manifold Pressures | ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| Natural |

| LP (Propane) | ||

Inlet Minimum |

|

| 5.5” w.c. |

| 11.0” w.c. | |||

Inlet Maximum |

|

| 14.0” w.c. |

| 14.0” w.c. | |||

Manifold Pressure | 3.5” w.c. |

| 10.0” w.c. | |||||

|

|

|

|

|

|

|

|

|

High Elevations

Input ratings are shown in BTU per hour and are certified without deration for elevations up to 4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA, installations must be in accordance with the cur- rent ANSI Z223.1/NFPA 54 and/or local codes hav- ing jurisdiction.

In Canada, please consult provincial and/or local authorities having jurisdiction for installations at elevations above 4,500 feet (1,370m).

Gas Line Installation

When purging the gas lines, the front win- dow frame assembly must be removed.

The gas pipeline can be brought in through the rear of the appliance as well as the bottom. Knockouts are provided on the bottom behind the valve to allow for the gas pipe installation and testing of any gas connection. It is most convenient to bring the gas line in from the rear right side of the valve as this allows fan installation or removal without disconnecting the gas line.

The gas line connection can be made with properly tinned 3/8” copper tubing, 3/8” rigid pipe or an ap- proved flex connector. Since some municipalities have additional local codes, it is always best to consult your local authority and the National Fuel Gas Code, ANSI Z223.1/NFPA 54 in the USA or the

Always check for gas leaks with a mild soap and water solution applied with a brush no larger than 1” (25 mm). Never apply soap and water solution with a spray bottle. Do not use an open flame for leak testing.

6 | 10009459 |