Horizontal plane means no vertical rise exists on this portion of the vent assembly.

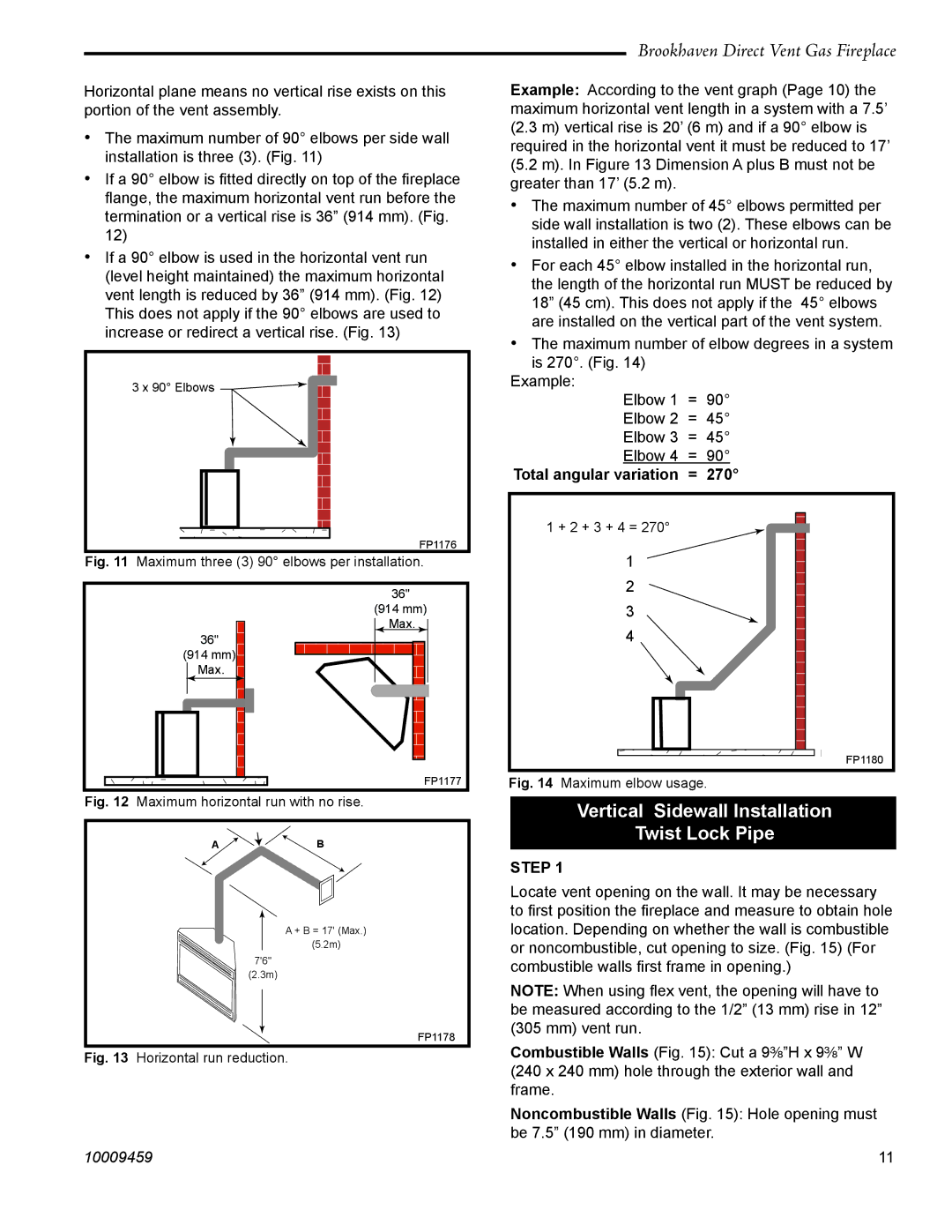

•The maximum number of 90° elbows per side wall installation is three (3). (Fig. 11)

•If a 90° elbow is fitted directly on top of the fireplace flange, the maximum horizontal vent run before the termination or a vertical rise is 36” (914 mm). (Fig.

12)

•If a 90° elbow is used in the horizontal vent run (level height maintained) the maximum horizontal vent length is reduced by 36” (914 mm). (Fig. 12) This does not apply if the 90° elbows are used to increase or redirect a vertical rise. (Fig. 13)

3 x 90° Elbows ![]()

FP1176

Fig. 11 Maximum three (3) 90° elbows per installation.

36"

(914 mm)

![]() Max. 36"

Max. 36" ![]()

(914 mm) Max.

FP1177

Fig. 12 Maximum horizontal run with no rise.

AB

A + B = 17' (Max.)

(5.2m)

7'6"

(2.3m)

FP1178

Fig. 13 Horizontal run reduction.

Brookhaven Direct Vent Gas Fireplace

Example: According to the vent graph (Page 10) the maximum horizontal vent length in a system with a 7.5’ (2.3 m) vertical rise is 20’ (6 m) and if a 90° elbow is required in the horizontal vent it must be reduced to 17’ (5.2 m). In Figure 13 Dimension A plus B must not be greater than 17’ (5.2 m).

•The maximum number of 45° elbows permitted per side wall installation is two (2). These elbows can be installed in either the vertical or horizontal run.

•For each 45° elbow installed in the horizontal run, the length of the horizontal run MUST be reduced by 18” (45 cm). This does not apply if the 45° elbows are installed on the vertical part of the vent system.

•The maximum number of elbow degrees in a system is 270°. (Fig. 14)

Example:

Elbow 1 = 90°

Elbow 2 = 45°

Elbow 3 = 45°

Elbow 4 = 90°

Total angular variation = 270°

1 + 2 + 3 + 4 = 270°

1

2

3

4

FP1180

Fig. 14 Maximum elbow usage.

Vertical Sidewall Installation

Twist Lock Pipe

STEP 1

Locate vent opening on the wall. It may be necessary to first position the fireplace and measure to obtain hole location. Depending on whether the wall is combustible or noncombustible, cut opening to size. (Fig. 15) (For combustible walls first frame in opening.)

NOTE: When using flex vent, the opening will have to be measured according to the 1/2” (13 mm) rise in 12” (305 mm) vent run.

Combustible Walls (Fig. 15): Cut a 9³⁄₈”H x 9³⁄₈” W (240 x 240 mm) hole through the exterior wall and frame.

Noncombustible Walls (Fig. 15): Hole opening must be 7.5” (190 mm) in diameter.

10009459 | 11 |