Gas Hookup

NATURAL GAS SUPPLY CONNECTION

TO CONNECT:

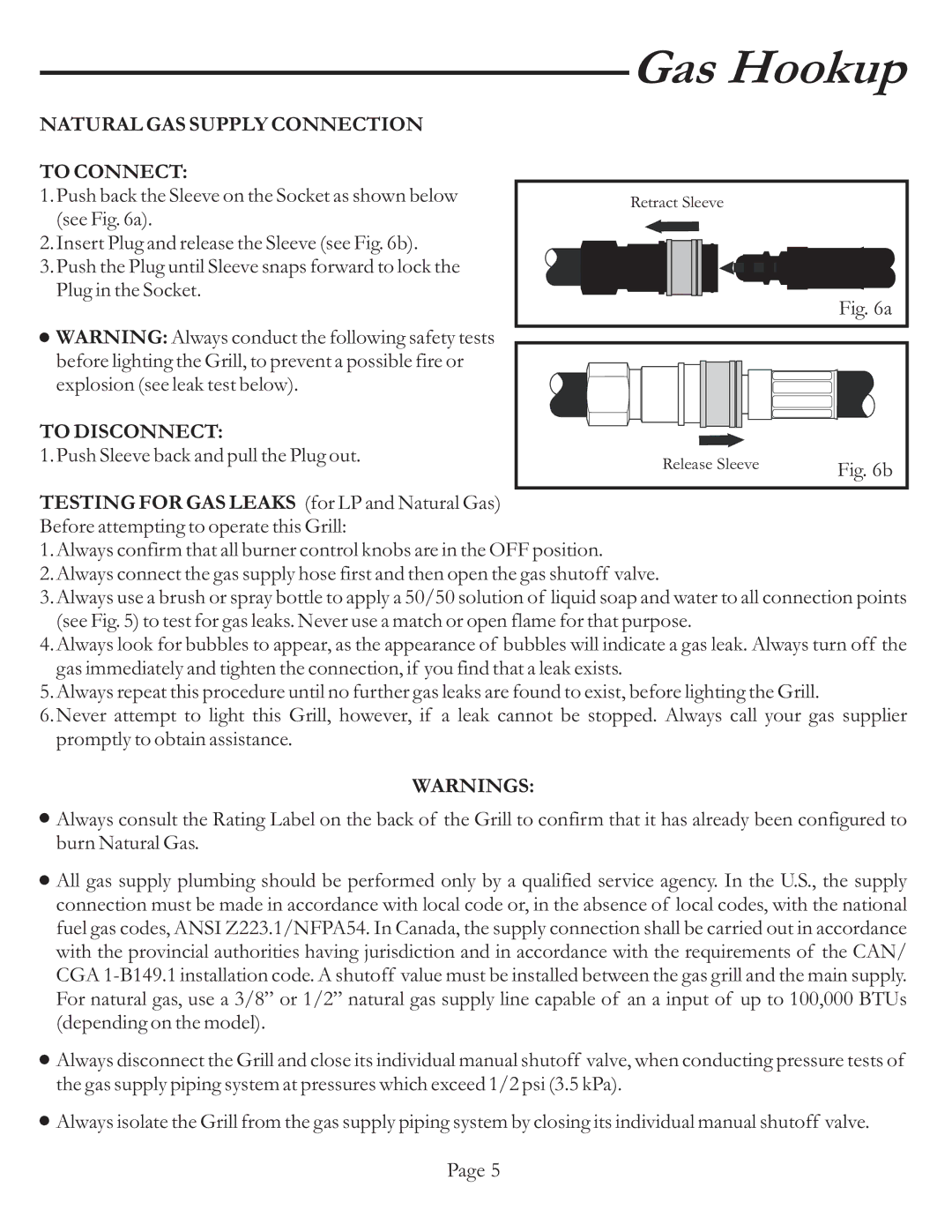

1.Push back the Sleeve on the Socket as shown below (see Fig. 6a).

2.Insert Plug and release the Sleeve (see Fig. 6b).

3.Push the Plug until Sleeve snaps forward to lock the Plug in the Socket.

![]() WARNING: Always conduct the following safety tests before lighting the Grill, to prevent a possible fire or explosion (see leak test below).

WARNING: Always conduct the following safety tests before lighting the Grill, to prevent a possible fire or explosion (see leak test below).

TO DISCONNECT:

1. Push Sleeve back and pull the Plug out.

Retract Sleeve |

Fig. 6a |

Release Sleeve |

|

Release Sleeve | Fig. 6b |

|

TESTING FOR GAS LEAKS (for LP and Natural Gas)

Before attempting to operate this Grill:

1.Always confirm that all burner control knobs are in the OFF position.

2.Always connect the gas supply hose first and then open the gas shutoff valve.

3.Always use a brush or spray bottle to apply a 50/50 solution of liquid soap and water to all connection points (see Fig. 5) to test for gas leaks. Never use a match or open flame for that purpose.

4.Always look for bubbles to appear, as the appearance of bubbles will indicate a gas leak. Always turn off the gas immediately and tighten the connection, if you find that a leak exists.

5.Always repeat this procedure until no further gas leaks are found to exist, before lighting the Grill.

6.Never attempt to light this Grill, however, if a leak cannot be stopped. Always call your gas supplier promptly to obtain assistance.

WARNINGS:

![]() Always consult the Rating Label on the back of the Grill to confirm that it has already been configured to burn Natural Gas.

Always consult the Rating Label on the back of the Grill to confirm that it has already been configured to burn Natural Gas.

![]() All gas supply plumbing should be performed only by a qualified service agency. In the U.S., the supply connection must be made in accordance with local code or, in the absence of local codes, with the national fuel gas codes, ANSI Z223.1/NFPA54. In Canada, the supply connection shall be carried out in accordance with the provincial authorities having jurisdiction and in accordance with the requirements of the CAN/ CGA

All gas supply plumbing should be performed only by a qualified service agency. In the U.S., the supply connection must be made in accordance with local code or, in the absence of local codes, with the national fuel gas codes, ANSI Z223.1/NFPA54. In Canada, the supply connection shall be carried out in accordance with the provincial authorities having jurisdiction and in accordance with the requirements of the CAN/ CGA

![]() Always disconnect the Grill and close its individual manual shutoff valve, when conducting pressure tests of the gas supply piping system at pressures which exceed 1/2 psi (3.5 kPa).

Always disconnect the Grill and close its individual manual shutoff valve, when conducting pressure tests of the gas supply piping system at pressures which exceed 1/2 psi (3.5 kPa).

![]() Always isolate the Grill from the gas supply piping system by closing its individual manual shutoff valve.

Always isolate the Grill from the gas supply piping system by closing its individual manual shutoff valve.

Page 5