F20686, DSOE305TSS, DSOE305T specifications

The Viking DSOE305T, DSOE305TSS, and F20686 are notable enclosed engine-driven welders that exemplify high performance and reliability in demanding environments. Designed for industrial and commercial applications, these machines deliver robust functionality while maintaining ease of use.Starting with the DSOE305T model, it boasts a powerful output rating of 305 amps, making it suitable for a variety of welding applications, including MIG, TIG, and stick welding. This versatility is further enhanced by its ability to handle different types of welding electrodes, making it the go-to choice for contractors and fabricators alike. The machine features an integrated circuit breaker, which protects against overloads and ensures longevity in diverse working conditions.

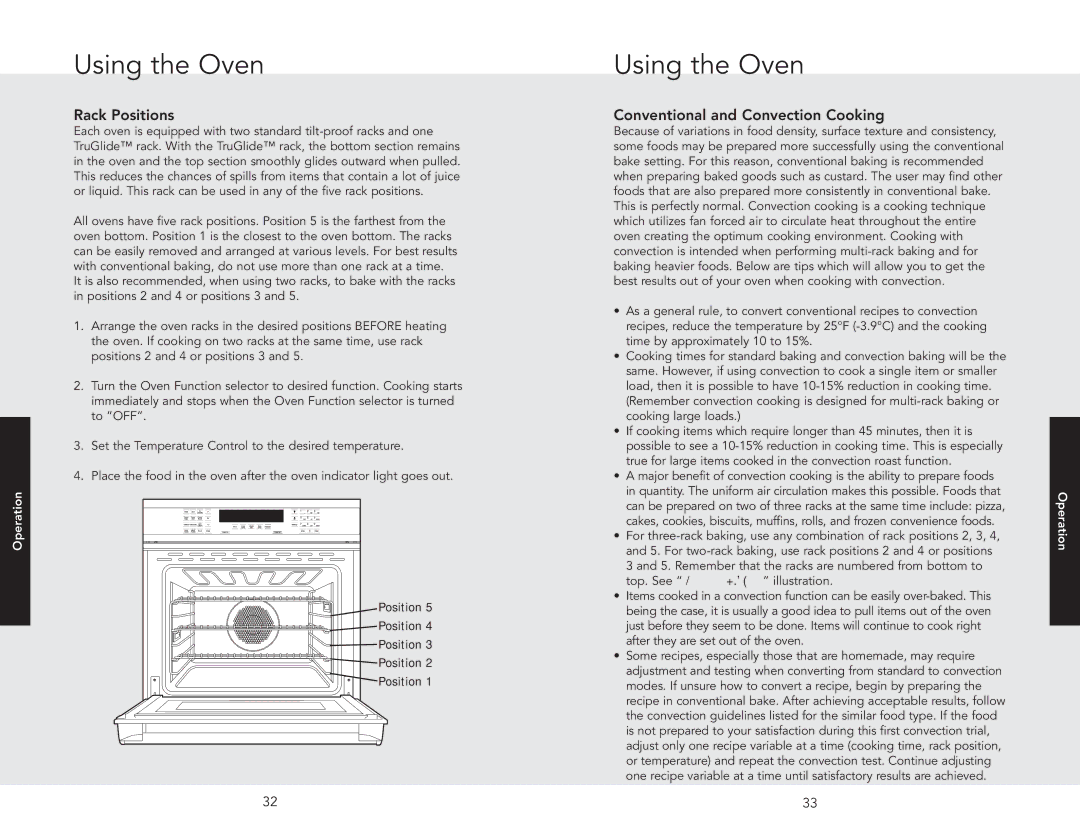

The DSOE305TSS variant adds an extra layer of convenience with its dual voltage capability, allowing operators to switch between 120V and 230V power supplies without the need for additional equipment. This flexibility is particularly advantageous for users working on various job sites where power sources may differ. Additionally, it is equipped with a user-friendly digital display, providing real-time information on output settings and operational status to help navigate through jobs more efficiently.

Equally impressive is the F20686 model, which emphasizes portability without compromising on power. This welder is designed to be lightweight and easily transportable, featuring sturdy yet compact construction. It can be utilized effectively in both workshop settings and on-site locations, making it ideal for a range of industries, from automotive repair to metal fabrication.

All models utilize advanced inverter technology, which not only contributes to their compact size but also significantly improves energy efficiency when compared to traditional welding machines. The ability to deliver a precise arc minimizes spatter, leading to cleaner welds and reduced post-welding cleanup.

Safety is also a paramount consideration in these machines. They come equipped with features such as overheating protection and a safety lock mechanism to prevent unauthorized operation.

In summary, the Viking DSOE305T, DSOE305TSS, and F20686 are engineered to meet the rigorous demands of modern welding applications. Their combination of power, versatility, mobility, and safety features makes them a reliable choice for welders seeking performance and efficiency in their work.