2.Units for operation of natural or propane gas are also equipped with a factory preset pressure regulator with an outlet pressure of 5” W.C. (Water Column) for natural gas supply and 10” W.C. for propane gas supply, and should not require further adjustment.

3.The burners and pilot flames may be observed through round holes in the front panel.

GAS PRESSURE MEASUREMENT

1.Set the power ON/OFF switch to the OFF position.

2.Turn the gas supply off at manual shutoff valve.

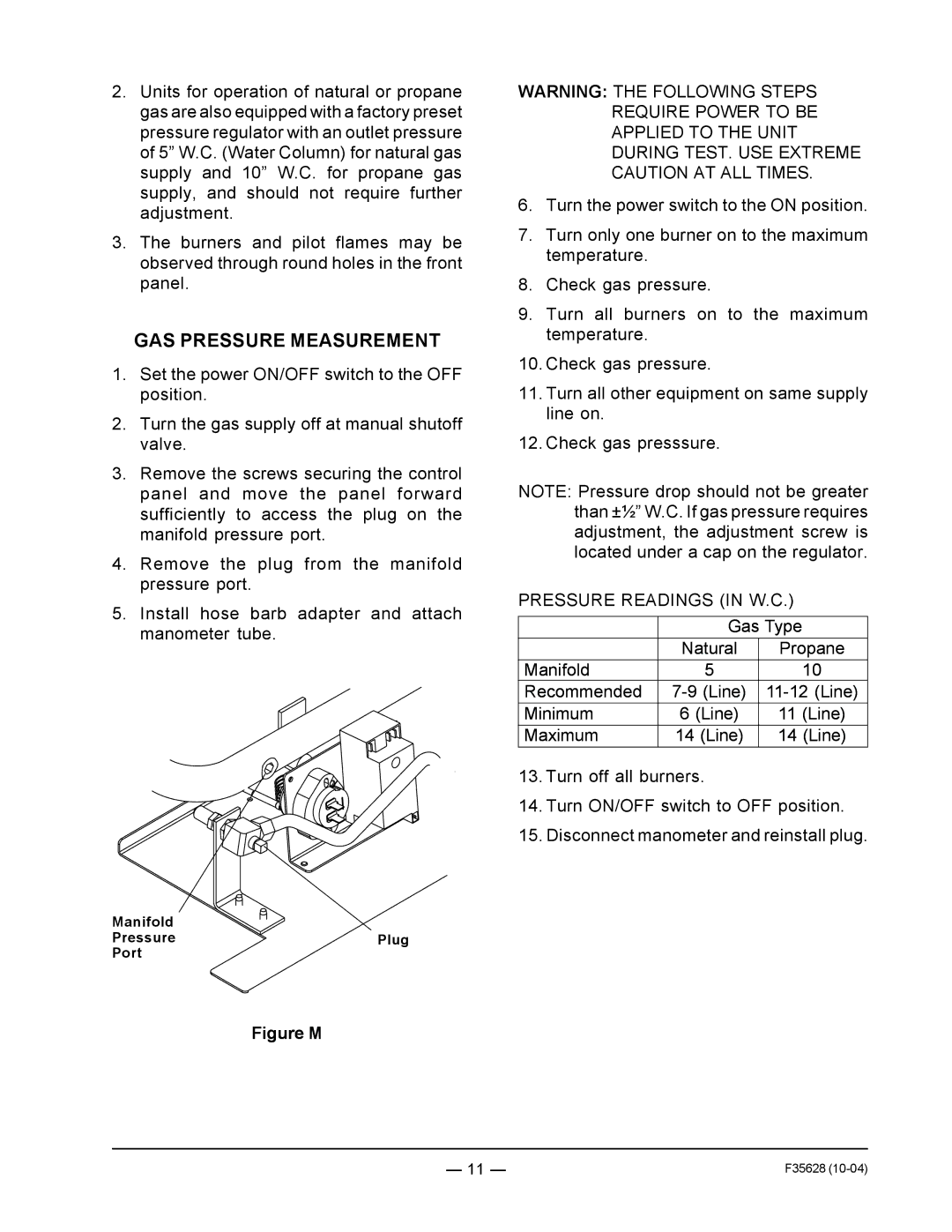

3.Remove the screws securing the control panel and move the panel forward sufficiently to access the plug on the manifold pressure port.

4.Remove the plug from the manifold pressure port.

5.Install hose barb adapter and attach manometer tube.

Manifold

PressurePlug

Port

Figure M

WARNING: THE FOLLOWING STEPS REQUIRE POWER TO BE APPLIED TO THE UNIT DURING TEST. USE EXTREME CAUTION AT ALL TIMES.

6.Turn the power switch to the ON position.

7.Turn only one burner on to the maximum temperature.

8.Check gas pressure.

9.Turn all burners on to the maximum temperature.

10.Check gas pressure.

11.Turn all other equipment on same supply line on.

12.Check gas presssure.

NOTE: Pressure drop should not be greater than ±½” W.C. If gas pressure requires adjustment, the adjustment screw is located under a cap on the regulator.

PRESSURE READINGS (IN W.C.)

| Gas Type | |

| Natural | Propane |

Manifold | 5 | 10 |

Recommended | ||

Minimum | 6 (Line) | 11 (Line) |

Maximum | 14 (Line) | 14 (Line) |

13.Turn off all burners.

14.Turn ON/OFF switch to OFF position.

15.Disconnect manometer and reinstall plug.

— 11 — | F35628 |