ERD40 specifications

The Vulcan-Hart ERD40 is a premium commercial deep fryer designed for high-volume food service operations. Renowned for its durability and efficiency, this fryer is a staple in restaurants, catering services, and other culinary establishments where consistent performance and speed are paramount.One of the standout features of the ERD40 is its impressive cooking capacity. With a large frying pot, the fryer can handle substantial volumes of food, making it ideal for busy kitchen environments. It typically includes twin fry pots which allows simultaneous frying of different food items, enhancing productivity and serving speed without compromising on quality.

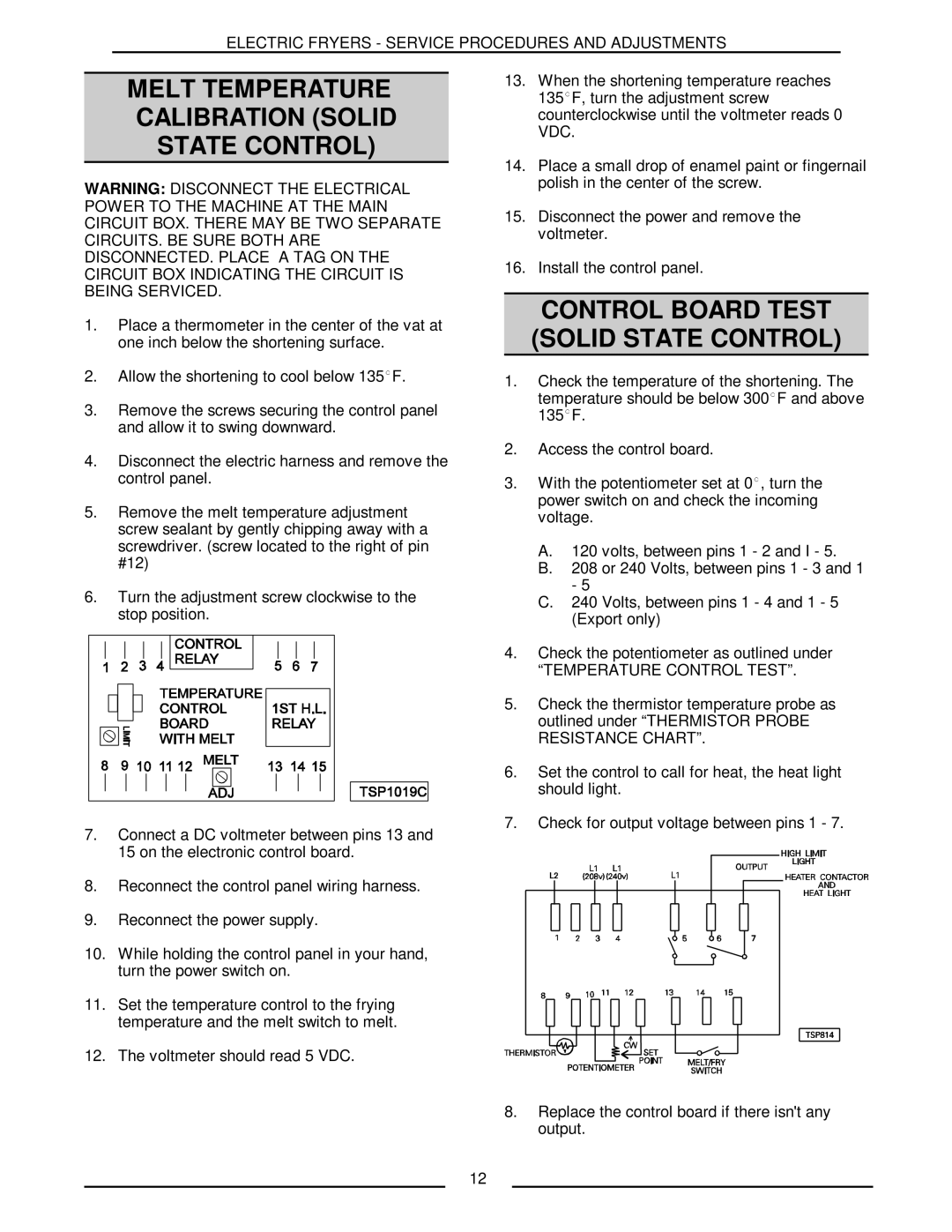

The fryer is equipped with advanced temperature control technology, which ensures precise temperature regulation. This feature is crucial for achieving perfect frying results and maintaining the quality of fried foods. The temperature can be easily adjusted, providing the flexibility needed for different cooking requirements.

Another key technology incorporated into the Vulcan-Hart ERD40 is its efficient oil filtration system, which helps extend the life of the cooking oil. This system filters out food particles and contaminants, keeping the oil clean and reducing the need for frequent oil changes. As a result, operators can save on both oil costs and maintenance time, ultimately increasing profitability.

The design of the ERD40 prioritizes user convenience and safety. It includes features such as a hinged lid for easy access and an ergonomic design to minimize the risk of spills and burns. Additionally, the fryer is constructed with robust materials that ensure longevity, even under heavy use.

Cleaning and maintenance are made straightforward with removable parts and easy-to-access components, allowing for quick disassembly and thorough cleaning. This attention to detail helps maintain hygiene standards crucial in food service environments.

With its combination of durability, efficiency, and advanced frying technology, the Vulcan-Hart ERD40 is an excellent investment for any commercial kitchen. It meets the demands of high-volume cooking while providing the reliability chefs depend on to serve high-quality dishes consistently.