CLEAN COOLING SYSTEII - Grass, chaff or dirt may

@dthe air cooling system, especiallyafter prolongedservicecutting dry grass.Yearly or every 100 hours, whichever occurs first, remove the blower housing and clean the

CLEAN OUT

CHAFFAND

DIRT

DANGER: Periodicallyclean muffler area to remove all grass,dirt and combustibledebris .

SPARK PLUG - Clean and reset gap at .030" every 100 hours of operation.

. 030" ( . 76mm)

FEELERGAUGE

CAUTION: Do not blast clean spark plug . Spark plug should be cleaned by scraping or wire brushing and washing with a commercialsolvent.

Sparkingcan occur if wire terminaldoes not fit . firmlyon spa+t<ptusi or if stop switetr+ib+ates agai+st spark plug. Reformterminal or repairswitch if necessary.

REMOVECOMBUSTIONDEPOSITSevery

SPARK ARRESTEREOUIPPEDMUFFLER- lf engine en assemblY, remove every 50 hours for cleaning and inspection.

Replaceif damaged .

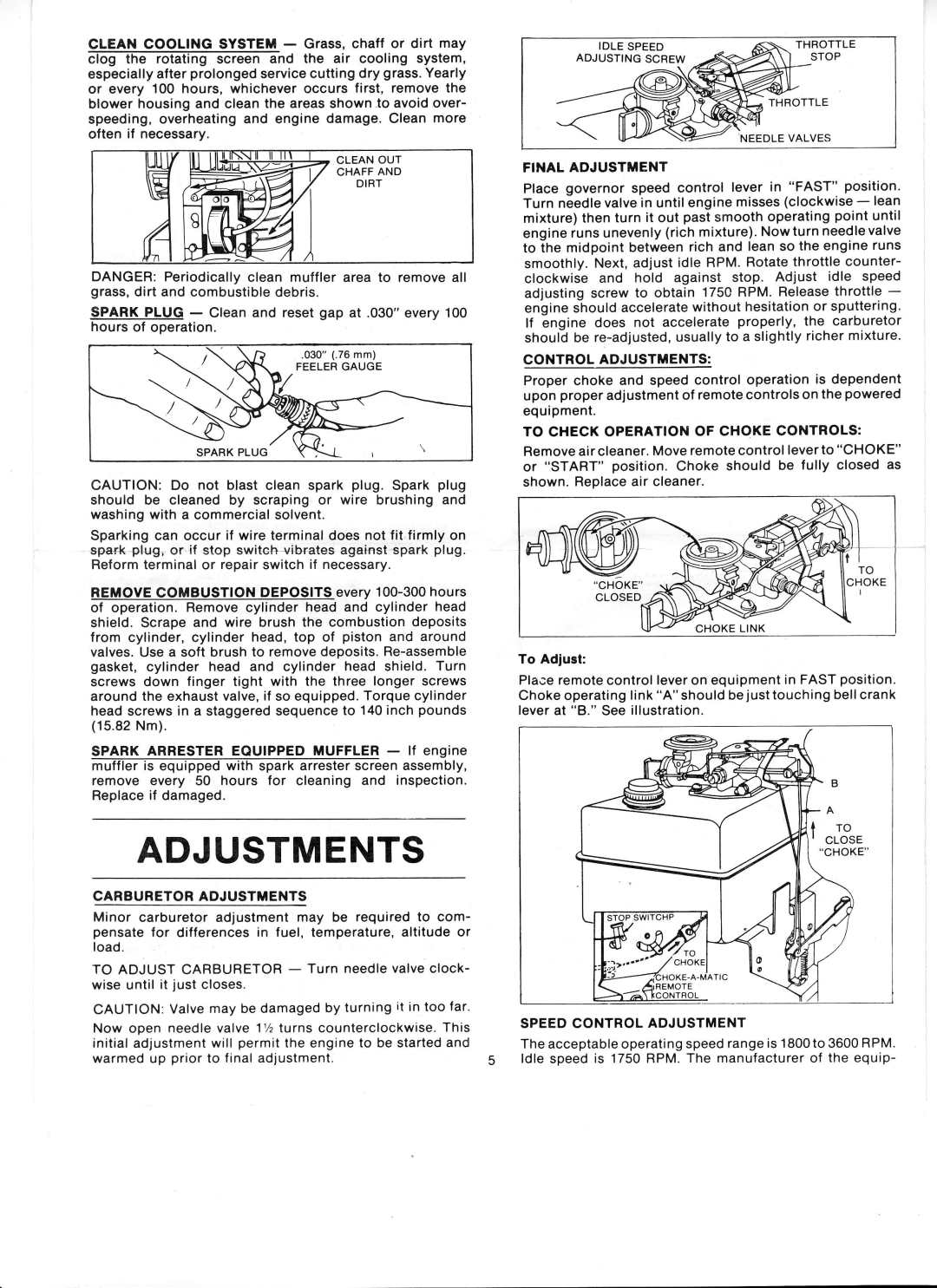

FINAL ADJUSTMENT

Place governor speed control lever in "FAST" position. Turn needlevalvein until engine misses(clockwise- lean mixture)then turn it out past smooth operatingpoint until engineruns unevenly(richmixture) .Nowturn needlevalve to the midpointbetweenrich and lean so the engineruns

smoothly. Next, adiust idle RPM. Rotatethrottle counter- clockwise and hold against stop . Adjust idle speed adjustingscrew to obtain 1750RPM . Releasethrottle - engineshouldacceleratewithouthesitationor sputtering . lf engine does not accelerate properly, the carburetor should be re - adjusted,usuallyto a slightlyrichermixture .

CONTROL ADJUSTMENTS:

Proper choke and speed control operation is dependent upon properadjustmentof remotecontrolson the powered

equipment .

TO CHECK OPERATIONOF CHOKE CONTROLS:

Removeair cleaner.Moveremotecontrol leverto"CHOKE" or "START" position . Choke should be fully closed as shown . Replaceair cleaner .

CHOKE LINK

To Adjust:

Placeremotecontrolleveron equipmentin FASTposition . Chokeoperatinglink"A"shouldbejusttouchingbellcrank

leverat "8 . " See illustration .

ADJUSTMENTS

CARBURETORADJUSTMENTS

Minor carburetor adjustment may be required to com- pensatelor differencesin fuel, temperature,altitude or load .

TO ADJUST CARBURETOR- Turn needlevalveclock - wise until it just closes .

CAUTION:Valvemay be damagedby turning it in too far'

Now open needlevalve 172turns counterclockwiseThis. initialadjustmentwill permitthe engineto be startedand warmed up prior to final adjustment .

SPEEDCONTROLADJUSTMENT

The acceptableoperatingspeedrangeis 1800to3600RPM . ldle speed is 1750RPM .The manufacturerof the equip -