|

|

|

| |

|

|

| Warning label | #4 |

|

|

|

| |

|

|

|

| Graduated |

5/16” x 1 5/8” Hex head lag screws | Top section | end hinge | ||

| ||||

| (as required) | screws (as required) |

| |

|

|

| #3 | #3 Graduated |

|

|

|

| |

|

|

| Warning label | end hinge |

(2) | (4) | Intermediate section | ||

Truss head bolts | Carriage bolts | Track bolts (as required) |

| |

|

|

| #2 | #2 Graduated |

|

|

|

| |

|

|

|

| end hinge |

Drawbar operator |

|

|

| Lock section |

| |

bracket arm |

|

|

| 7/8” | ||

|

|

|

| |||

|

|

|

|

|

| |

|

|

|

| #1 |

| #1 Graduated |

|

|

|

|

|

| |

|

|

|

|

| Bottom corner bracket warning labels | end hinge |

5/16” x |

| Cotter pin |

|

| Bottom corner | |

|

|

|

|

| Bottom section | |

|

|

|

| Astragal | bracket | |

|

|

|

|

| Astragal | |

|

|

|

|

|

| |

|

|

|

| Typical graduated end | Section side view illustration | |

|

|

| #10 x 5/8” | hinge stamping | ||

Pull handles (as required) | Lift handles (as required) | Phillips pan head screws | location |

|

| |

(black painted heads) |

|

|

| |||

#8 x | #8 x |

| Removing an Existing Door | |||

|

|

|

|

| ||

|

| Important: Counterbalance spring tension must always be released before any |

| 5/16” x | attempt is made to start removing an existing door. |

| lag screw (as required) | WARNING |

|

| |

|

| A powerful spring releasing its energy suddenly can cause severe |

| 5/16” x 2” | or fatal injury. To avoid injury, have a trained door systems tech- |

Counterbalance lift | nician, using proper tools and instructions, release the spring | |

cables | lag screw (as required) | tension. |

|

|

Door Section Identification | For detailed information see supplemental instructions “Removing an Existing Door/ Preparing | |

the Opening”. These instructions are not supplied with the door, but are available at no charge | ||

| from | |

| 44660, or at | |

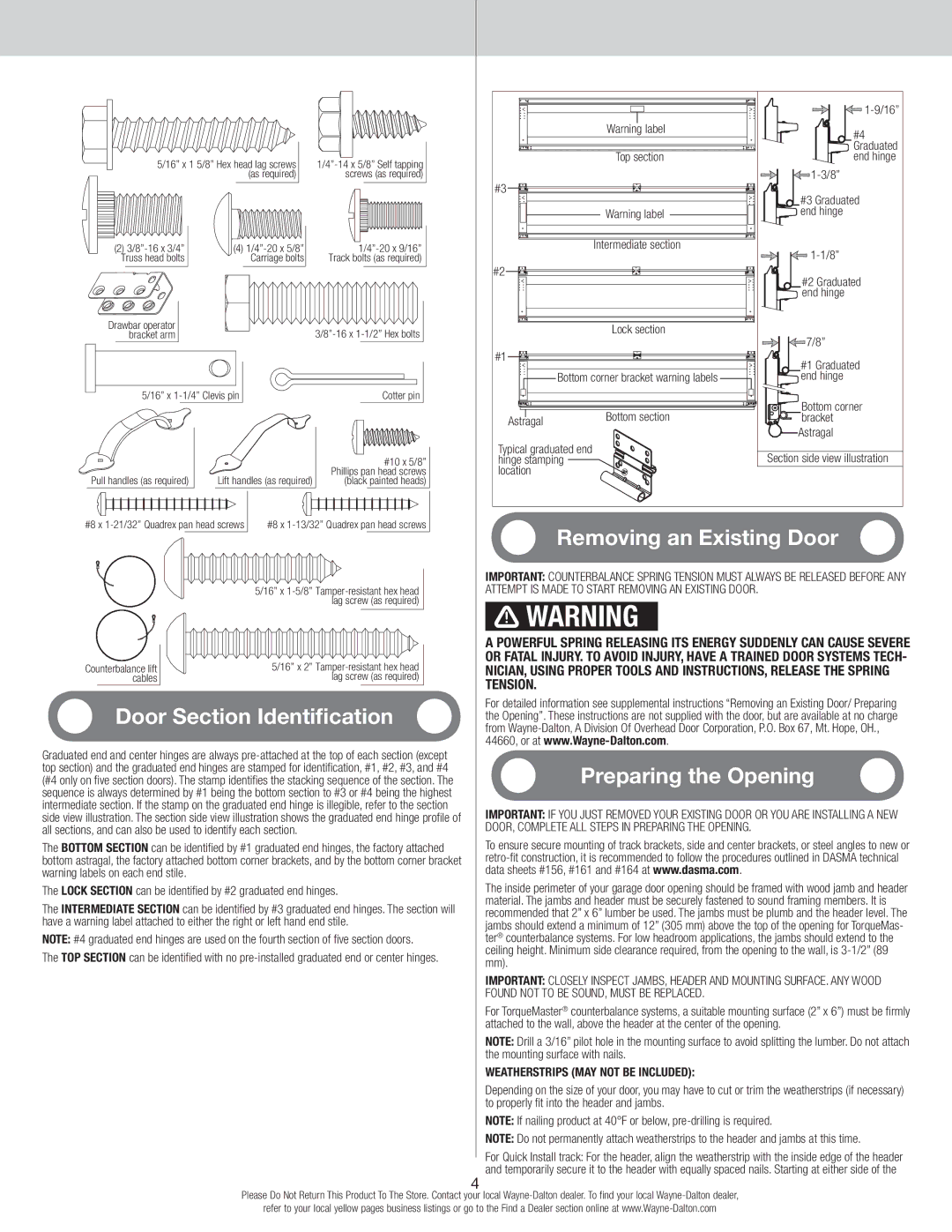

Graduated end and center hinges are always |

| |

top section) and the graduated end hinges are stamped for identification, #1, #2, #3, and #4 | Preparing the Opening | |

(#4 only on five section doors). The stamp identifies the stacking sequence of the section. The | ||

sequence is always determined by #1 being the bottom section to #3 or #4 being the highest |

| |

intermediate section. If the stamp on the graduated end hinge is illegible, refer to the section | IMPORTANT: If you just removed your existing door or you are installing a new | |

side view illustration. The section side view illustration shows the graduated end hinge profile of | ||

all sections, and can also be used to identify each section. | door, complete all steps in preparing the opening. | |

The BOTTOM SECTION can be identified by #1 graduated end hinges, the factory attached | To ensure secure mounting of track brackets, side and center brackets, or steel angles to new or | |

bottom astragal, the factory attached bottom corner brackets, and by the bottom corner bracket | ||

warning labels on each end stile. | data sheets #156, #161 and #164 at www.dasma.com. | |

The LOCK SECTION can be identified by #2 graduated end hinges. | The inside perimeter of your garage door opening should be framed with wood jamb and header | |

The INTERMEDIATE SECTION can be identified by #3 graduated end hinges. The section will | material. The jambs and header must be securely fastened to sound framing members. It is | |

recommended that 2” x 6” lumber be used. The jambs must be plumb and the header level. The | ||

have a warning label attached to either the right or left hand end stile. | ||

jambs should extend a minimum of 12” (305 mm) above the top of the opening for TorqueMas- | ||

| ||

Note: #4 graduated end hinges are used on the fourth section of five section doors. | ter® counterbalance systems. For low headroom applications, the jambs should extend to the | |

The TOP SECTION can be identified with no | ceiling height. Minimum side clearance required, from the opening to the wall, is | |

mm). | ||

| ||

| Important: Closely inspect jambs, header and mounting surface. Any wood | |

| found not to be sound, must be replaced. | |

| For TorqueMaster® counterbalance systems, a suitable mounting surface (2” x 6”) must be firmly | |

| attached to the wall, above the header at the center of the opening. | |

| Note: Drill a 3/16” pilot hole in the mounting surface to avoid splitting the lumber. Do not attach | |

| the mounting surface with nails. | |

| Weatherstrips (may not be included): | |

| Depending on the size of your door, you may have to cut or trim the weatherstrips (if necessary) | |

| to properly fit into the header and jambs. | |

| Note: If nailing product at 40°F or below, | |

| Note: Do not permanently attach weatherstrips to the header and jambs at this time. | |

| For Quick Install track: For the header, align the weatherstrip with the inside edge of the header | |

| and temporarily secure it to the header with equally spaced nails. Starting at either side of the |

4

Please Do Not Return This Product To The Store. Contact your local

refer to your local yellow pages business listings or go to the Find a Dealer section online at