7100 Series specifications

Wayne-Dalton's 7100 Series is a line of high-quality insulated steel garage doors designed to provide both style and functionality. These doors are characterized by their exceptional durability, energy efficiency, and aesthetic appeal, making them a popular choice among homeowners and builders alike.One of the standout features of the Wayne-Dalton 7100 Series is its construction. Made from double-layered steel with a core of expanded polystyrene insulation, these doors offer superior thermal performance. This insulation helps maintain a consistent temperature within the garage, which is especially beneficial in areas with extreme weather conditions. With an R-value of up to 10.15, the 7100 Series doors significantly reduce energy costs and enhance the comfort of adjacent living spaces.

In addition to energy efficiency, the 7100 Series is designed with sturdiness in mind. The steel construction is reinforced to withstand impact and resist denting, ensuring that the doors maintain their appearance even after years of use. This durability is further enhanced by a corrosion-resistant finish, which helps the doors resist rust and other forms of degradation.

Aesthetically, the Wayne-Dalton 7100 Series offers a range of design options. Homeowners can choose from several panel styles and colors to complement their home's exterior. The doors can also be customized with decorative hardware, including windows and handles, allowing for a personalized touch that enhances curb appeal.

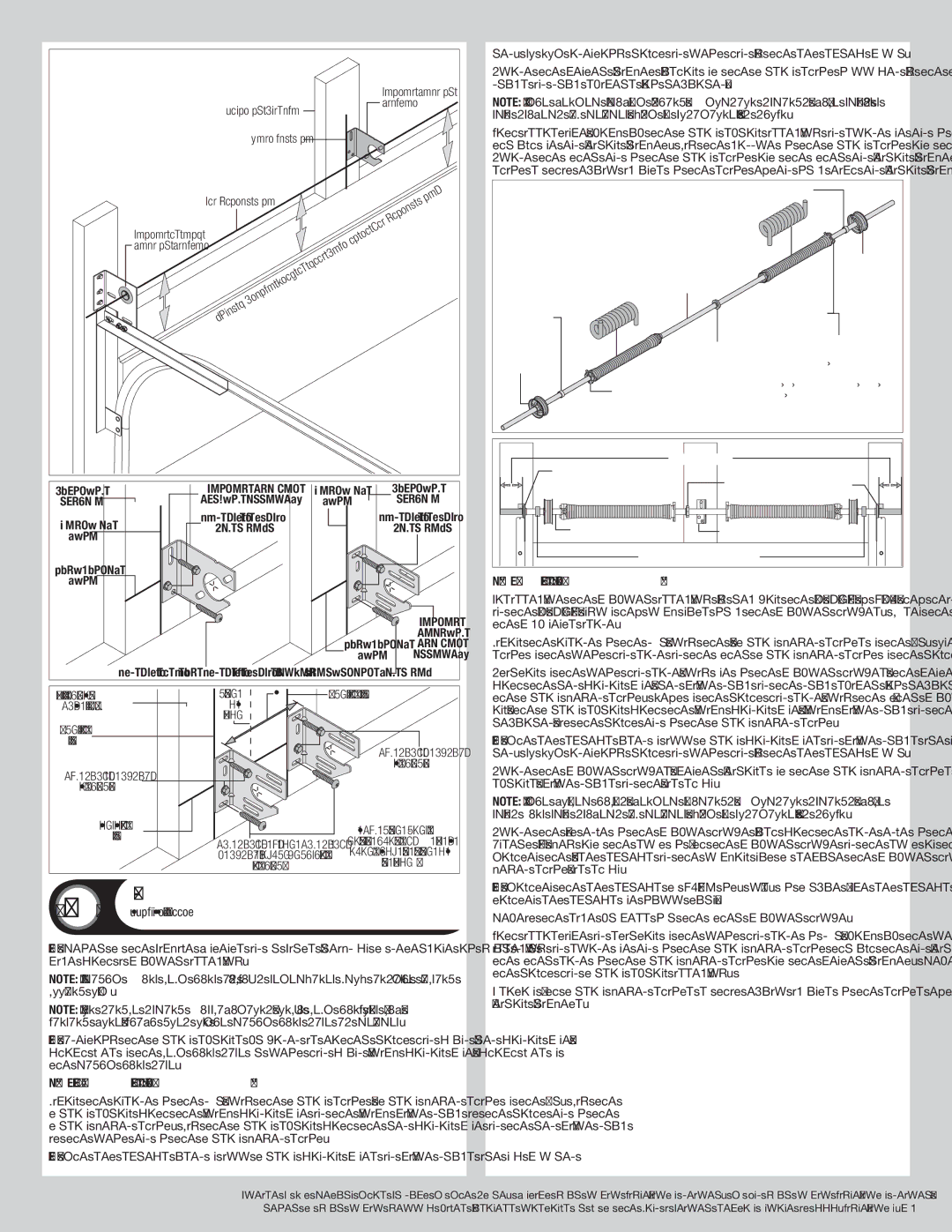

Wayne-Dalton incorporates advanced technology into the 7100 Series, making operation smooth and reliable. The doors are equipped with a high-quality torsion spring system, which ensures easy lifting and lower costs of maintenance. Additionally, the optional Wi-Fi-enabled garage door opener provides enhanced convenience and security, allowing users to monitor and control the door from their smartphones.

The 7100 Series also prioritizes safety, featuring pinch-resistant technology, which prevents fingers from getting caught during operation. This thoughtful design consideration makes the doors safer for families with children and pets.

In conclusion, the Wayne-Dalton 7100 Series is an excellent investment for anyone looking to upgrade their garage door. With its blend of durability, energy efficiency, aesthetic appeal, and advanced technological features, it stands out as one of the top choices on the market today. Whether for new construction or a remodel, this series offers homeowners a versatile and stylish solution for their garage door needs.