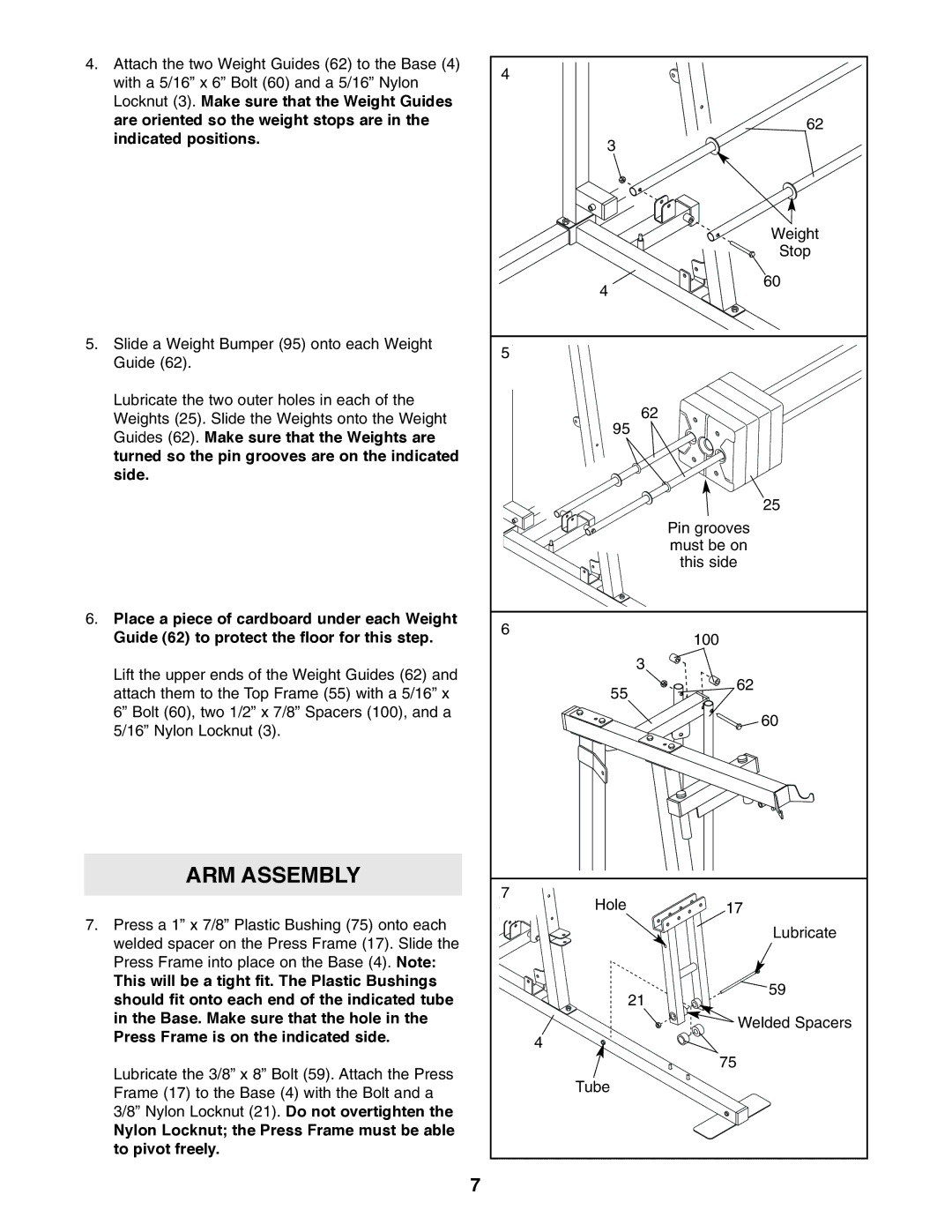

4.Attach the two Weight Guides (62) to the Base (4) with a 5/16” x 6” Bolt (60) and a 5/16” Nylon Locknut (3). Make sure that the Weight Guides are oriented so the weight stops are in the indicated positions.

5.Slide a Weight Bumper (95) onto each Weight Guide (62).

Lubricate the two outer holes in each of the Weights (25). Slide the Weights onto the Weight Guides (62). Make sure that the Weights are turned so the pin grooves are on the indicated side.

6.Place a piece of cardboard under each Weight Guide (62) to protect the floor for this step.

Lift the upper ends of the Weight Guides (62) and attach them to the Top Frame (55) with a 5/16” x 6” Bolt (60), two 1/2” x 7/8” Spacers (100), and a 5/16” Nylon Locknut (3).

ARM ASSEMBLY

7.Press a 1” x 7/8” Plastic Bushing (75) onto each welded spacer on the Press Frame (17). Slide the Press Frame into place on the Base (4). Note:

This will be a tight fit. The Plastic Bushings should fit onto each end of the indicated tube in the Base. Make sure that the hole in the Press Frame is on the indicated side.

Lubricate the 3/8” x 8” Bolt (59). Attach the Press Frame (17) to the Base (4) with the Bolt and a 3/8” Nylon Locknut (21). Do not overtighten the

Nylon Locknut; the Press Frame must be able to pivot freely.

4 |

|

| 62 |

3 |

|

| Weight |

| Stop |

4 | 60 |

| |

5 |

|

62 |

|

95 |

|

| 25 |

| Pin grooves |

| must be on |

| this side |

6 | 100 |

| |

3 |

|

55 | 62 |

| |

| 60 |

7 |

|

Hole | 17 |

| Lubricate |

21 | 59 |

| |

| Welded Spacers |

4 |

|

| 75 |

Tube |

|

7