CGi, PFG, PEG, LGB, CGs specifications

Weil-McLain is a highly regarded manufacturer of boilers and hydronic heating systems, well-known for its innovative approach and commitment to quality. Among its extensive product lineup, the PEG, LGB, CGs, PFG, and CGi series stands out due to their advanced engineering, efficiency, and reliability. Each series caters to varying residential and commercial heating needs, making them versatile options for consumers.The PEG series is recognized for its impressive efficiency ratings and robust construction. It utilizes a cast iron heat exchanger, which not only enhances heat retention but also ensures longevity. Its low water content and advanced control features allow for quick heating response times, making it ideal for homes requiring reliable heat. The PEG series is available in a range of sizes, ensuring a fit for any application.

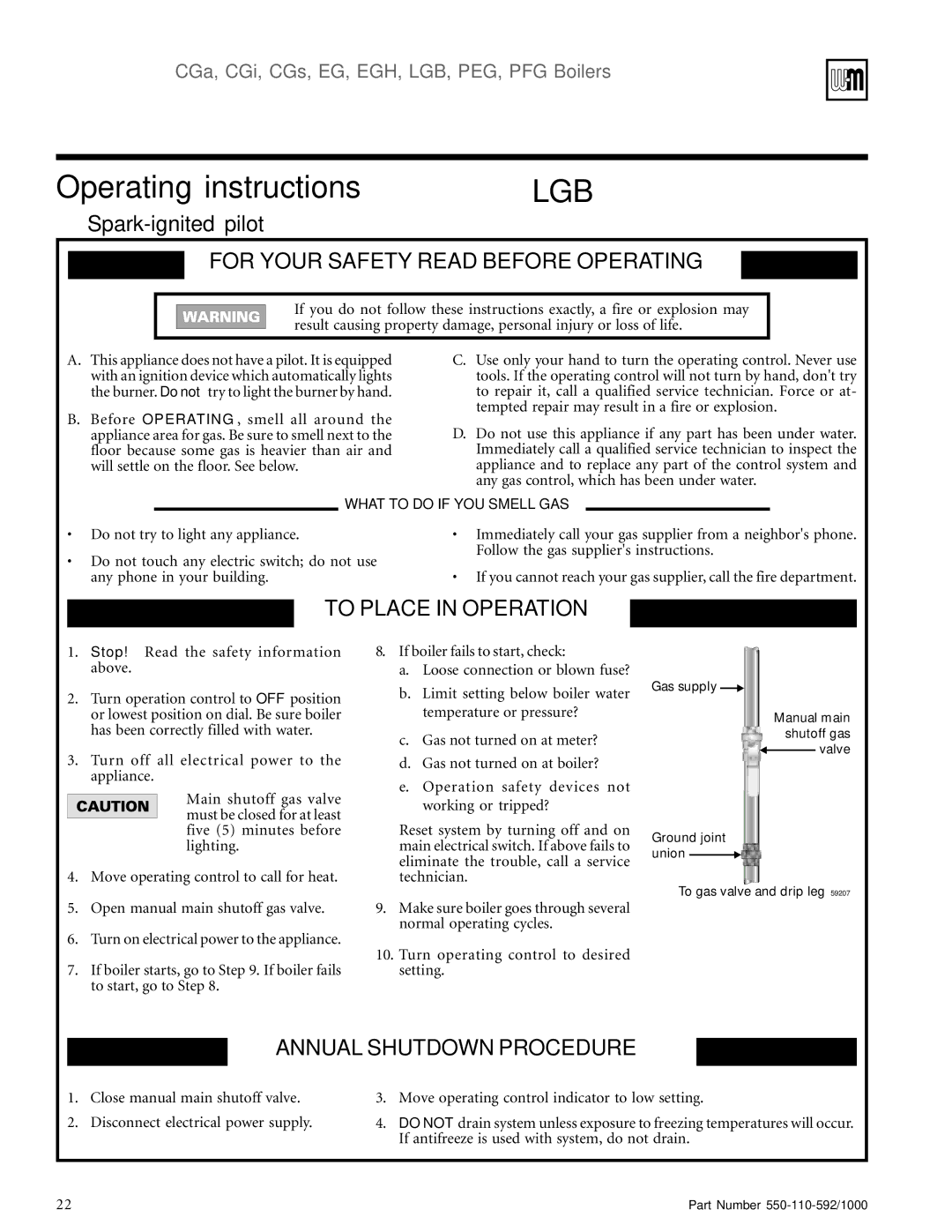

The LGB series is tailored for light commercial applications, combining efficiency with remarkable performance. Built with Weil-McLain’s signature high-grade cast iron, the LGB models are designed for durability and ease of maintenance. They offer an impressive thermal efficiency and feature a compact design, making them suitable for installations where space is a concern. Advanced options such as multiple venting configurations contribute to their versatility, adapting to various building designs.

The CGs series is specifically designed for commercial applications and emphasizes efficiency through advanced technology, including an intelligent control system that optimizes operation based on demand. Its low NOx design helps meet stringent environmental standards, while its robust build ensures high performance under heavy load conditions. The CGs is often sought after for larger facilities requiring consistent and efficient heating.

Weil-McLain’s PFG series takes efficiency to the next level with its highly efficient gas-fired design. It features a light-weight configuration and quick-connect venting options, which simplify installation. This series is known for its low emissions and high energy efficiency, making it an eco-friendly choice for today’s environmentally conscious consumers.

Lastly, the CGi series is a standout for residential applications, offering flexibility and ease of use. The series features a cast iron heat exchanger and is compatible with various control systems, providing an adaptable and efficient solution for home heating.

Overall, Weil-McLain’s PEG, LGB, CGs, PFG, and CGi series exemplify the company’s dedication to quality, energy efficiency, and customer satisfaction, providing reliable heating solutions for diverse applications.