B

If loc:l codes DO NOT permit

cablnetgroundlng to the neutral wires of the power supply cords:

1. Disconnect the power supply.

2.Attach a 3/4’.

3.Remove the grounding wires

(green wlth yellow stripes) from the external groundlng connectors and fasten under center,

Connect separate copper groundlng wlre from external grounding connector

to approved ground.

mower supply cord

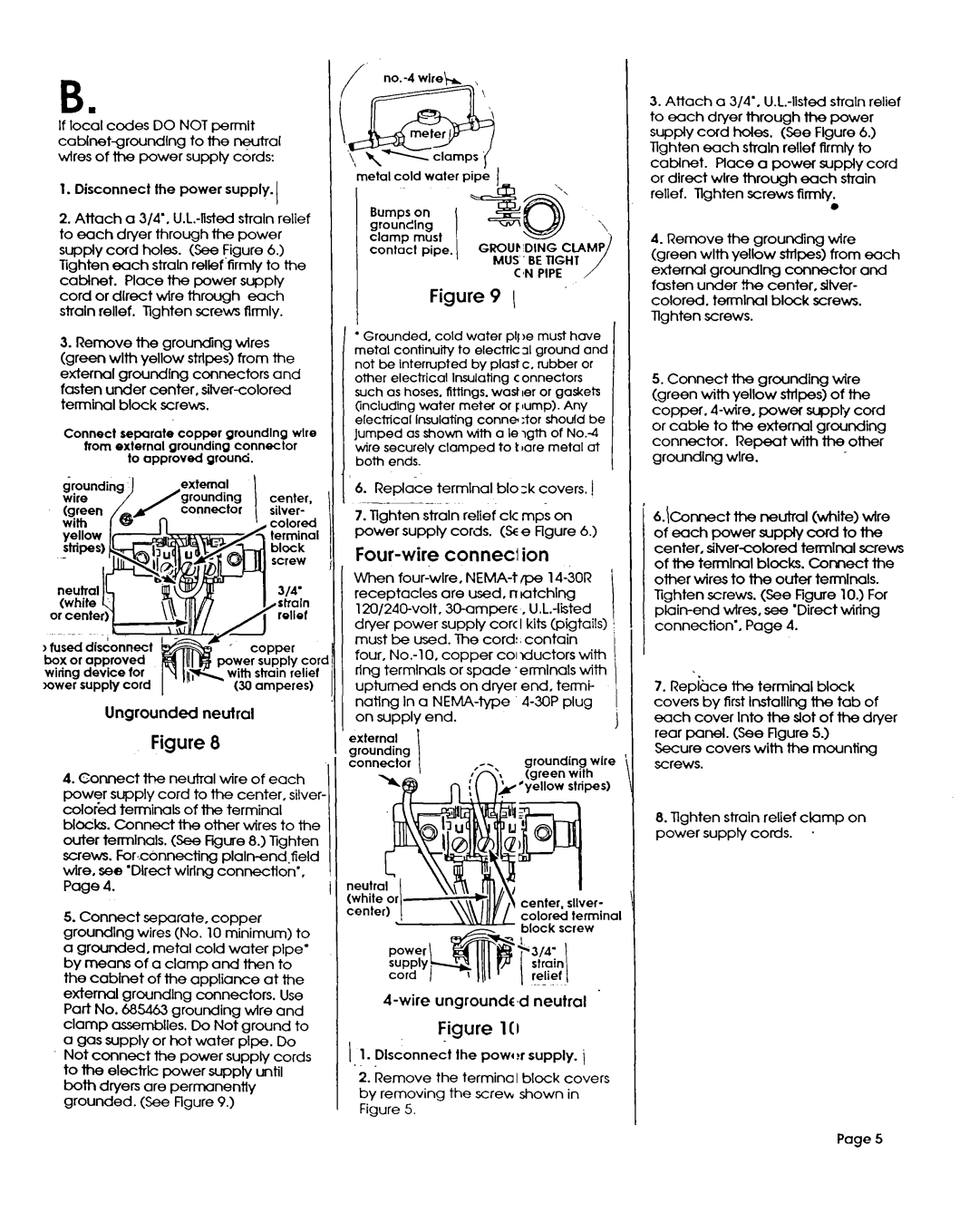

Ungrounded neutral

Figure 8

4.Connect the neutral wire of each power supply cord to the center, silver- color&d terminals of the terminal blocks. Connect the other wires to the outer termlnals. (See Fgure 8.) Tighten

screws. Forc6nnecting

5.Connect separate, copper

groundlng wires (No. 10 minimum) to a grounded, metal cold water pipe’ by means of a clamp and then to the cabinet of the appliance at the external groundlng connectors. Use Part No. 685463 grounding wire and clamp assemblies. Do Not ground to a gas supply or hot water pipe. Do Not connect the power supply cords to the electric power supply until bath dryers are permanently grounded. (See Figure 9.)

metal cold water pipe 1

Bumps on

grounllng *cB \ clamp must

contact pipe. I GROUF :DlNG CLAMP MUS BE TIGHT

C’N PIPE /

Figure 9 \

l Grounded. cold water plj )e must hove metal continuity to electric 31ground and not be interrupted by plast c. rubber or other electrical Insulating connectors such as hoses. fifflngs. wast ler or gaskets (including water meter or Flump). Any electrical Insulating tonne :tor should be jumped as shown with a le igth of

6.Replace termlnal blo zk covers. )

7.Tighten straln relief ck mps on power supply cords. (SEe Flgure 6.)

Four-wire conned ion

When fouriwlre,

nating In a

4-wire ungroundcmd neutral .

Figure 1[1

1. Disconnect the powder supply. i

2.Remove the terminal block covers by removing the screw shown in Figure 5.

3.Attach a 3/4’,

l

4. Remove the grounding wire (green with yellow stripes) from each external groundlng connector and fasten under the center, sitver- colored. termlnal block screws. llghten screws.

5.Connect the grounding wire (green with yellow stripes) of the copper.

connector. Remt with the other grounding wire.

&\Connect the neutral (white) wire of each power supply card to the center,

connection’. Page 4.

7.Red&e the terminal block covers by first InstallIng the tab of each cover Into the slot of the dryer rear panel. (See Figure 5.)

Secure covers with the mounting screws.

8.Tlghten straln relief clamp on

power supply cords. .

Page 5