Electrical requirements.

OBSERVE AU GOVEdNlNG COdES

AND ORDINANCES.

Electrical Shock Hazard

. Electrical ground Is required on this appliance.

. If cold water pipe Is interrupted by plastic,

. Do Not ground to a gas pipe.

. Do Not modify the power supply cord plugs. iflplugs will not fit the outlets, have proper outlets installed by a qualified electrician.

. Use new

. Do Not have a fuse in the neutral or grounding circuit. A fuse in the neutral or grounding circuit could result in an electrical shock.

. Do Not use an extension cord with this appliance.

. Check with a qualified electrician if you are in doubt as to whether the appliance is properly grounded.

.1Do Not plug the power supply cords (pigtails) into a live wail receptacle before connecting the pigtails to the dryer terminal blocks. Read ‘Direct

wiring connectton’. Pages 4 and 5 for detailed instructions.

F:aiiure to follow these instructions

c:ouid result in serious injury or death.

I ” codes | permit | and | a Separate | ’ | |

9’rounding wire Is used, it is recom- |

| ||||

mlended | that | a eiectriclan | determine |

| |

thtat the | grounding | path | Is adequate. |

| |

*. It

a:;ylr& that the electrlcai Installation is adequate and In conforjmance

w WI Natlonal ElectrIcal Code ANSI/ NIFPA

aI Dpllance so that It can be moved if SErrvlclng is ever necessary.

ihis appliance must be connectec to copper wlre only,

A 3/4’.

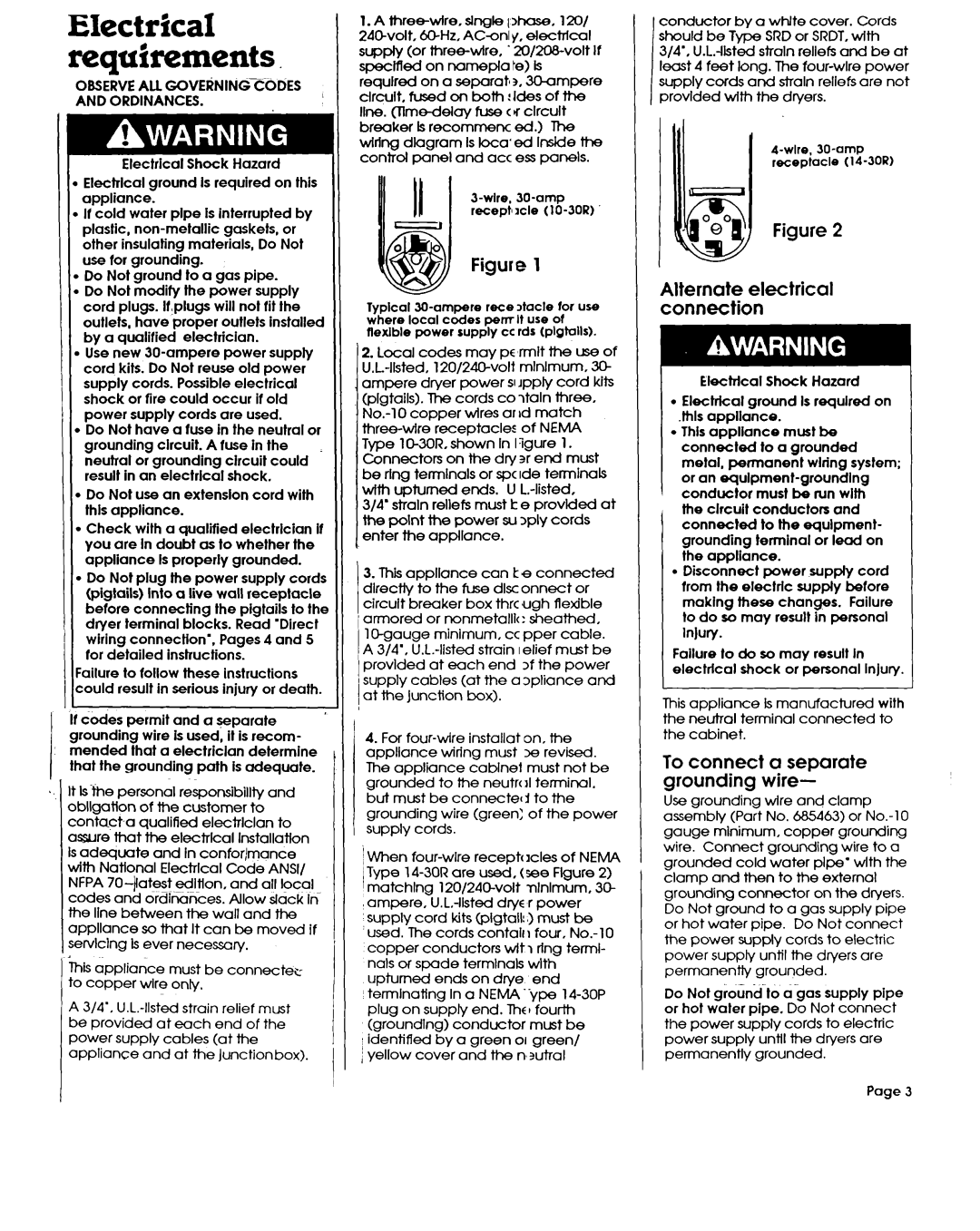

1.A

line.

recepL ~cie

Figure 1

Typical

2. Local codes may pc ~rrnlt the USB of

3/4’ strain reliefs must t 8 provlded at the polnt the power su >ply cords enter the appliance.

3. This appliance can t 8 connected dlrecity to the fuse disconnect or circuit breaker box thrcugh flexible

iarmored or nonmetallic: sheathed, lOgauge minimum, cc pper cable. A 3/4’,

1supply cables (at the a Dpliance and at the junction box).

4.For

must be connectec 1 to me grounding wire (green: of the power supply cords.

iWhen

: identified by a green OI green/ j yellow cover and the n, ?&al

CConductor by a white cover. Cords Skmuld be Type SRD or SRDT, with 3,/4’.

Figure 2

LIternate electrical :onnection

Eiectrlcal Shock Hazard

l Electrical ground Is required on

.this appilance.

l This appliance must be connected to a grounded

metal. permanent wiring system; or an

the circuit conductors and connected to the equipment- grounding terminal or lead on the appliance.

l Disconnect power supply cord from the electric supply before making these changes. Failure to do so may result in personal injury.

Failure to do so may result in electrical shock or personal injury.

his appliance ls manufactured with ie neutral terminal connected to Cle cabinet.

‘0 connect a separate younding wire-

Jse grounding wire and clamp lssembiy (Part No. 685463) or

permanently grounded.

Do Not ground to &gas supply pipe or hot water pipe, Do Not connect the power supply cords to electric power supply until the dryers are permanently grounded.

Page 3