Guided’utilisationetd’entretien

W10054070A

Table of Contents

Índice

Dryer Safety

Your safety and the safety of others are very important

LocationRequirements

Installation Instructions

ToolsandParts

Electrical Requirements-U.S.A.Only

Mobile home Additional installation requirements

Mobile home installations require

It is your responsibility

If connecting by direct wire

ElectricalRequirements-CanadaOnly

Style 1 Power supply cord strain relief

Power Supply Cord Direct Wire

Install strain relief

ElectricalConnection-U.S.A.Only

Wire connection Power supply cord

Style 2 Direct wire strain relief

Wire connection Direct Wire

Remove center silver-colored terminal block screw

BDE CG F

Optional 3-wire connection

If this is a new vent system Vent material

If using an existing vent system

VentingRequirements

PlanVentSystem

Alternate installations for close clearances

Special provisions for mobile home installations

Determine vent path

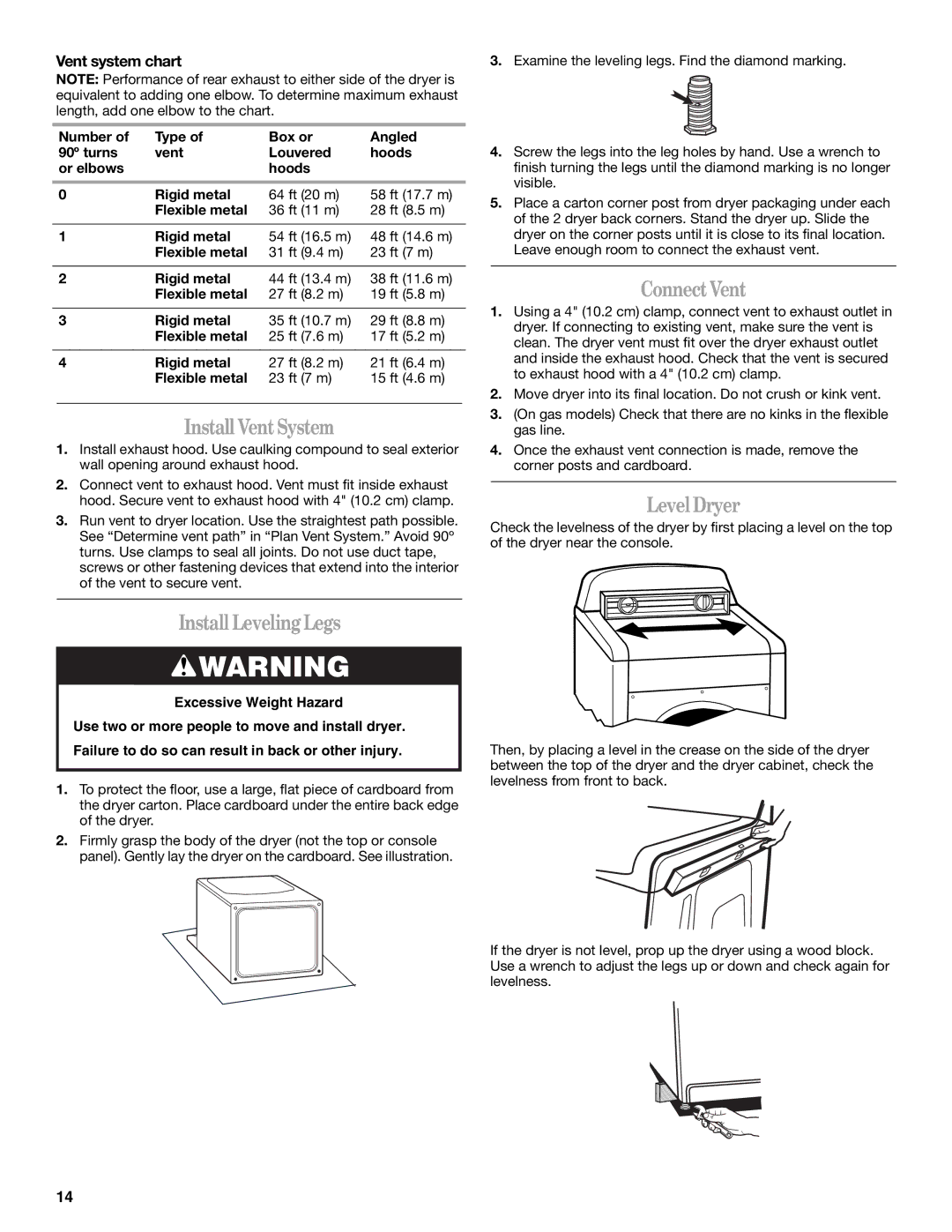

Vent system chart

Install VentSystem

Install LevelingLegs

ConnectVent

ReverseDoorSwing

Remove the door assembly

Reinstall the door

Reverse the strike

Canada

CompleteInstallation

U.S.A

If the dryer will not start, check the following

StartingYourDryer

Press PAUSE/CANCEL

Dryer USE

To use an Automatic Cycle

StatusLights

Stopping,PausingorRestarting

DryingandCycleTips

Cycles

Modifiers Options

ChangingCycles,Modifiers andOptions

Endof CycleSignal

DryingRackOption

CleaningtheLintScreen

CleaningtheDryer Location

CleaningtheDryerInterior

Dryer Care

ChangingtheDrumLight

Troubleshooting

VacationandMovingCare

DryerOperation

DryerResults

Dryer displaying code message

InCanada

Assistance or Service

TheU.S.A

Whirlpool Corporation Major Appliance Warranty

Call

Page

Seguridad DE LA Secadora

Su seguridad y la seguridad de los demás es muy importante

Requisitos deubicación

Instrucciones DE Instalación

Herramientasypiezas

Espacios de instalación

Dimensiones de la secadora

Requisitos eléctricos -Sóloen EE.UU

Usted es responsable de

Si el contacto de pared luce como éste

Conexión eléctrica

Si emplea un cable de suministro eléctrico

Si hace la conexión con cableado directo

Instale el protector de cables

Conexión eléctrica-SóloenEE.UU

Cable de suministro eléctrico Cable directo

Alambre de 4 hilos se recomienda

Conexión de 4 hilos Cable de suministro eléctrico

Estilo 2 Protector de cables para cable directo

Alambre de 3 hilos si no dispone de alambre de 4 hilos

Conexión de 4 hilos Cable directo

Conexión de 3 hilos Cable de suministro eléctrico

Conexión de 3 hilos Cable directo

Si usa un sistema de ventilación existente

Requisitosdeventilación

Conexión opcional de 3 hilos

Si éste es un nuevo sistema de ventilación

Planificacióndelsistemadeventilación

Determinación de la vía del ducto de escape

Instalación del sistemadeventilación

Instalaciones alternas para espacios limitados

Cuadro del sistema de ventilación

Nivelacióndelasecadora

Instalacióndelaspatasniveladoras

Conexióndel ductodeescape

Abra la puerta de la secadora

Cómo invertirel cierredelapuerta

Cómo quitar el ensamblaje de la puerta

Cómo invertir el tope

Completelainstalación-EE.UU

Si la secadora no funciona, revise lo siguiente

Para usar un ciclo automático

USO DE LA Secadora

Puestaenmarchadelasecadora

Para reanudar la marcha de la secadora

Para hacer cambios durante un ciclo automático

Cómo detener,pausaryvolveraponeren marcha

Cómo funciona el sistema de secado AccelerCare

Sugerenciasdeciclosy secado

Lucesdeestado

Ciclos

Modificadores

Opciones

Opción deestantedesecado

Señal defin deciclo EndofCycleSignal

Cambiodeciclos,modificadores yopciones

Limpiezadel filtrodepelusa

Cuidado DE LA Secadora

Limpiezadellugardondeestálasecadora

Limpieza de cada carga

Cambiodelaluz del tambor

Limpiezadel interiordelasecadora

Eliminacióndepelusaacumulada

Cuidadodurantelasvacacionesymudanzas

Solución DE Problemas

Funcionamientodelasecadora

¿Está la secadora ubicada en un armario?

Resultadosdelasecadora

¿Está el filtro de pelusa obstruido con pelusa?

Ayuda O Servicio Técnico

Whirlpool Corporation

En EE.UU., llame al 1-800-253-1301. En Canadá, llame al

Sécurité DE LA Sécheuse

Votre sécurité et celle des autres est très importante

Outillageetpièces

Instructions D’INSTALLATION

Exigences d’emplacement

Spécifications électriques-PourleCanada Seulement

Dimensions de la sécheuse

Linstallation dans une maison mobile exige

Dégagements de séparation à respecter

Conduit métallique rigide

Exigencesconcernantlévacuation

En cas dutilisation du système dévacuation existant

Conduit métallique flexible

Brides de serrage

Les styles de clapets recommandés sont illustrés ci-dessous

Planification dusystèmed’évacuation

Évacuation

Tableau des systèmes dévacuation

Déterminer litinéraire dacheminement du conduit

Une réduction de la longévité de la sécheuse

Raccordementduconduitd’évacuation

Installation dusystèmed’évacuation

Installation despiedsderéglagedel’aplomb

Réglagedelaplomb dela sécheuse

Dépose de la porte

Réinstallation de la porte

Inversiondusensdouverturedelaporte

Inversion de la gâche

Si la sécheuse ne démarre pas, vérifier ce qui suit

Acheverlinstallation

Fermer la porte vérifier l’engagement de la gâche

Utilisation dun programme automatique

Utilisation DE LA Sécheuse

Miseenmarchedelasécheuse

Pour mettre la sécheuse en pause ou larrêter à tout moment

Arrêt,pauseouremiseenmarche

Conseils pourleséchageetles programmes

Pour remettre la sécheuse en marche

Témoins lumineux

Programmes

Modificateurs

Signaldefin deprogramme

Modification des préréglages de niveau de séchage

Optiondegrilledeséchage

Changement des programmes après avoir appuyé sur Start

Utilisation de la grille de séchage

Nettoyage avant chaque charge

Nettoyagedelemplacementdelasécheuse

Nettoyagedufiltreàcharpie

Déménagement

Nettoyagedel’intérieurdelasécheuse

Retraitdelacharpieaccumulée

Changementdel’ampouled’éclairage Du tambour

Dépannage

Fonctionnementdela sécheuse

Le filtre à charpie est-il obstrué de charpie?

La sécheuse est-elle installée dans un placard?

Résultats delasécheuse

Le conduit dévacuation a-t-il la longueur appropriée?

Taches sur la charge ou sur le tambour

Temps de programme trop court

Charpie sur la charge

Charges avec faux plis

Pour plus d’assistance

Assistance OU Service

Si vous avez besoin de pièces de rechange

Pour trouver des pièces de rechange FSP dans votre région

W10054070A

Garantie DES Gros Appareils Ménagers Whirlpool Corporation

Composer le 1-800-253-1301. Au Canada, composer le

![]() WARNING

WARNING