MAINTENANCE

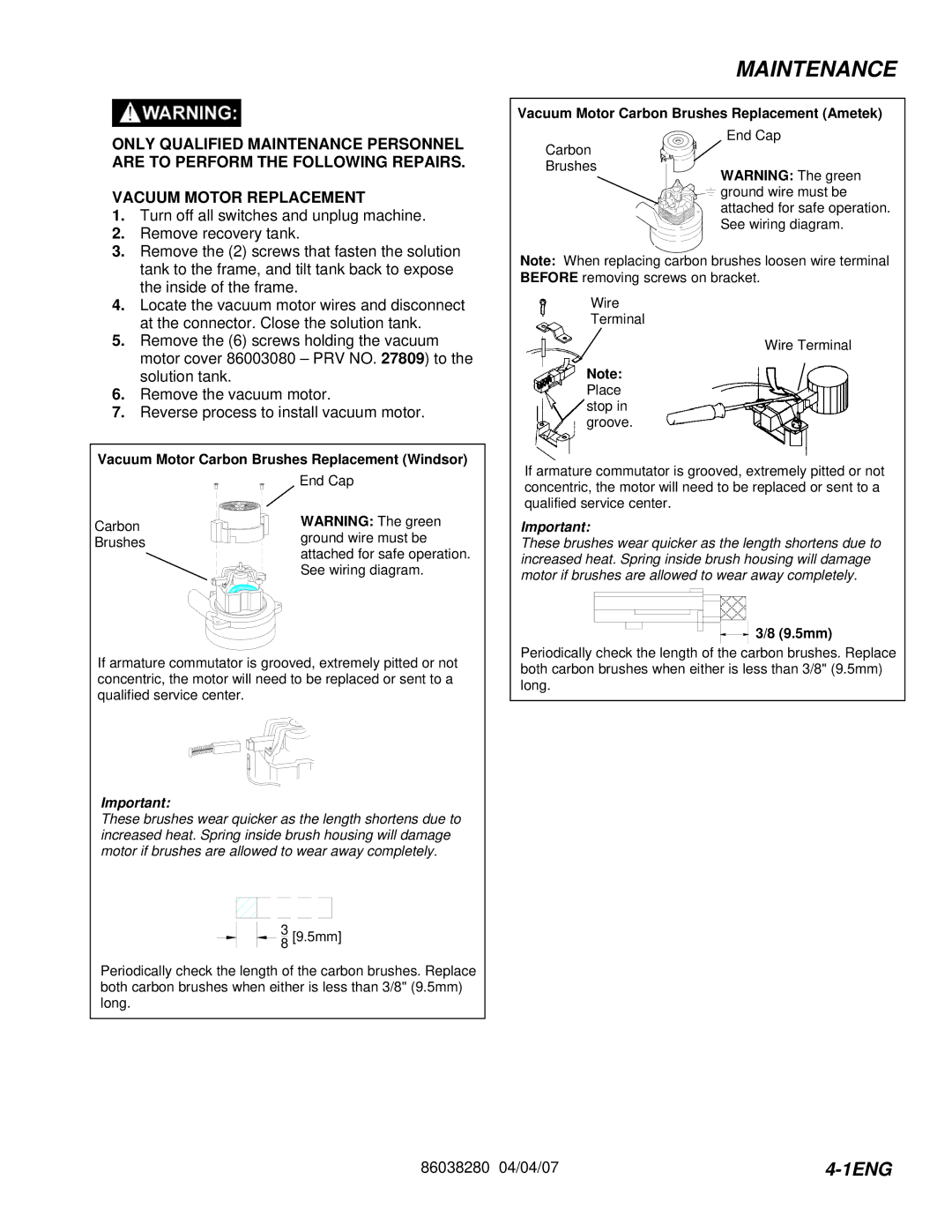

Vacuum Motor Carbon Brushes Replacement (Ametek)

ONLY QUALIFIED MAINTENANCE PERSONNEL ARE TO PERFORM THE FOLLOWING REPAIRS.

VACUUM MOTOR REPLACEMENT

1. | Turn off all switches and unplug machine. |

2. | Remove recovery tank. |

3. | Remove the (2) screws that fasten the solution |

Carbon Brushes

End Cap

WARNING: The green ![]()

![]()

![]()

![]()

![]()

![]() ground wire must be

ground wire must be

attached for safe operation. See wiring diagram.

| tank to the frame, and tilt tank back to expose |

| the inside of the frame. |

4. | Locate the vacuum motor wires and disconnect |

| at the connector. Close the solution tank. |

5. | Remove the (6) screws holding the vacuum |

| motor cover 86003080 – PRV NO. 27809) to the |

| solution tank. |

6. | Remove the vacuum motor. |

7. | Reverse process to install vacuum motor. |

Vacuum Motor Carbon Brushes Replacement (Windsor)

| End Cap |

Carbon | WARNING: The green |

Brushes | ground wire must be |

| attached for safe operation. |

| See wiring diagram. |

If armature commutator is grooved, extremely pitted or not concentric, the motor will need to be replaced or sent to a qualified service center.

Important:

These brushes wear quicker as the length shortens due to increased heat. Spring inside brush housing will damage motor if brushes are allowed to wear away completely.

![]() 38 [9.5mm]

38 [9.5mm]

Periodically check the length of the carbon brushes. Replace both carbon brushes when either is less than 3/8" (9.5mm) long.

Note: When replacing carbon brushes loosen wire terminal BEFORE removing screws on bracket.

Wire

Terminal

Wire Terminal

Note:

Place stop in groove.

If armature commutator is grooved, extremely pitted or not concentric, the motor will need to be replaced or sent to a qualified service center.

Important:

These brushes wear quicker as the length shortens due to increased heat. Spring inside brush housing will damage motor if brushes are allowed to wear away completely.

3/8 (9.5mm)

Periodically check the length of the carbon brushes. Replace both carbon brushes when either is less than 3/8" (9.5mm) long.

86038280 04/04/07 |