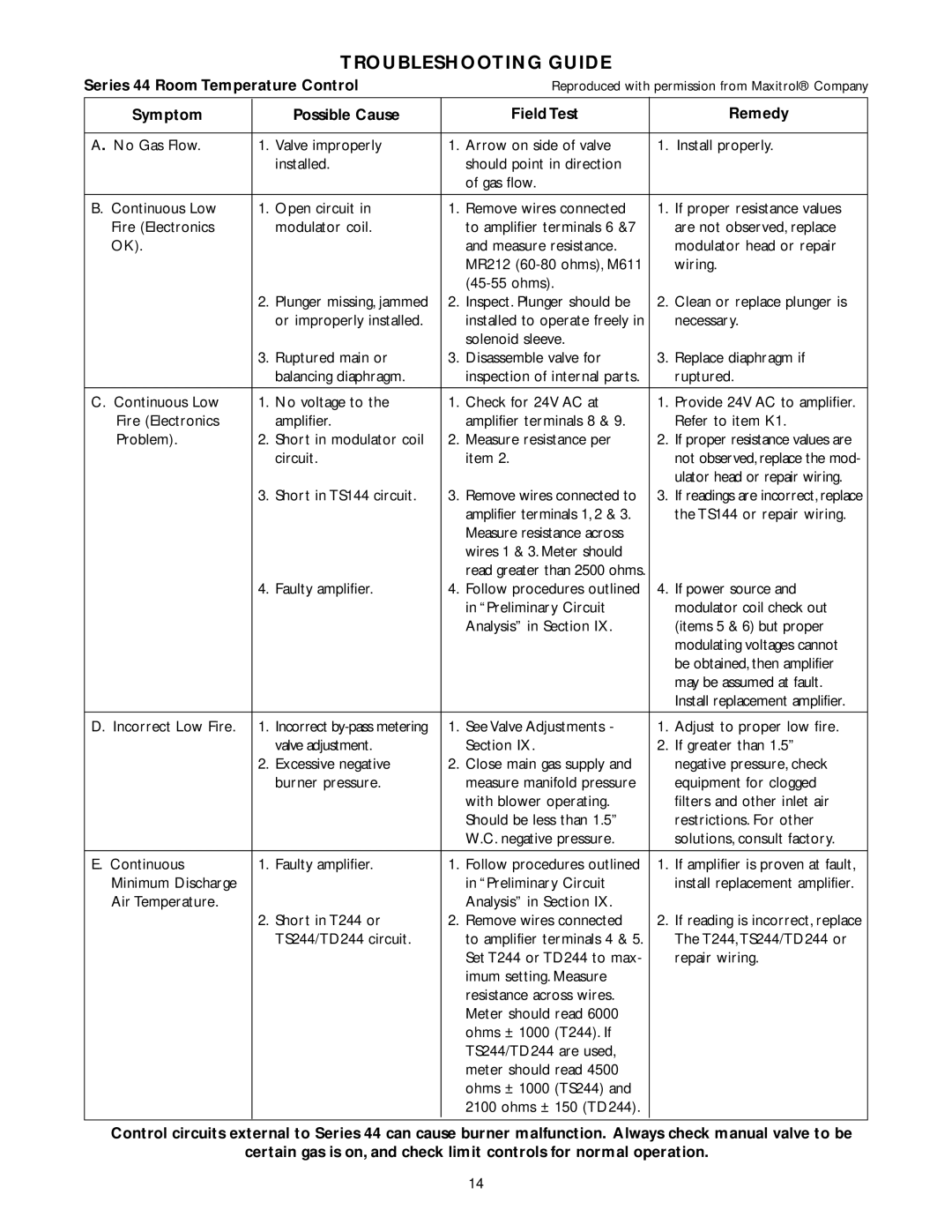

TROUBLESHOOTING GUIDE

Series 44 Room Temperature Control |

| Reproduced with permission from Maxitrol® Company | |||||

Symptom |

|

| Possible Cause |

| Field Test |

| Remedy |

|

|

|

|

|

|

|

|

A. No Gas Flow. |

|

|

| 1. | Arrow on side of valve | 1. | Install properly. |

1. | Valve improperly | ||||||

|

|

| installed. |

| should point in direction |

|

|

|

|

|

|

| of gas flow. |

|

|

|

|

|

|

|

|

|

|

B. Continuous Low |

| 1. | Open circuit in | 1. | Remove wires connected | 1. | If proper resistance values |

Fire (Electronics |

|

| modulator coil. |

| to amplifier terminals 6 &7 |

| are not observed, replace |

OK). |

|

|

|

| and measure resistance. |

| modulator head or repair |

|

|

|

|

| MR212 |

| wiring. |

|

|

|

|

|

|

| |

|

| 2. | Plunger missing, jammed | 2. | Inspect. Plunger should be | 2. | Clean or replace plunger is |

|

|

| or improperly installed. |

| installed to operate freely in |

| necessary. |

|

|

|

|

| solenoid sleeve. |

|

|

|

| 3. | Ruptured main or | 3. | Disassemble valve for | 3. | Replace diaphragm if |

|

|

| balancing diaphragm. |

| inspection of internal parts. |

| ruptured. |

|

|

|

|

|

|

|

|

C. Continuous Low |

| 1. | No voltage to the | 1. | Check for 24V AC at | 1. | Provide 24V AC to amplifier. |

Fire (Electronics |

|

| amplifier. |

| amplifier terminals 8 & 9. |

| Refer to item K1. |

Problem). |

| 2. | Short in modulator coil | 2. | Measure resistance per | 2. | If proper resistance values are |

|

|

| circuit. |

| item 2. |

| not observed, replace the mod- |

|

|

|

|

|

|

| ulator head or repair wiring. |

|

| 3. | Short in TS144 circuit. | 3. | Remove wires connected to | 3. If readings are incorrect, replace | |

|

|

|

|

| amplifier terminals 1, 2 & 3. |

| the TS144 or repair wiring. |

|

|

|

|

| Measure resistance across |

|

|

|

|

|

|

| wires 1 & 3. Meter should |

|

|

|

|

|

|

| read greater than 2500 ohms. |

|

|

|

| 4. | Faulty amplifier. | 4. | Follow procedures outlined | 4. | If power source and |

|

|

|

|

| in “Preliminary Circuit |

| modulator coil check out |

|

|

|

|

| Analysis” in Section IX. |

| (items 5 & 6) but proper |

|

|

|

|

|

|

| modulating voltages cannot |

|

|

|

|

|

|

| be obtained, then amplifier |

|

|

|

|

|

|

| may be assumed at fault. |

|

|

|

|

|

|

| Install replacement amplifier. |

|

|

|

|

|

|

|

|

D. Incorrect Low Fire. |

| 1. | Incorrect | 1. | See Valve Adjustments - | 1. | Adjust to proper low fire. |

|

|

| valve adjustment. |

| Section IX. | 2. | If greater than 1.5” |

|

| 2. | Excessive negative | 2. | Close main gas supply and |

| negative pressure, check |

|

|

| burner pressure. |

| measure manifold pressure |

| equipment for clogged |

|

|

|

|

| with blower operating. |

| filters and other inlet air |

|

|

|

|

| Should be less than 1.5” |

| restrictions. For other |

|

|

|

|

| W.C. negative pressure. |

| solutions, consult factory. |

|

|

|

|

|

|

|

|

E. Continuous |

| 1. | Faulty amplifier. | 1. | Follow procedures outlined | 1. | If amplifier is proven at fault, |

Minimum Discharge |

|

|

|

| in “Preliminary Circuit |

| install replacement amplifier. |

Air Temperature. |

|

|

|

| Analysis” in Section IX. |

|

|

|

| 2. | Short in T244 or | 2. | Remove wires connected | 2. | If reading is incorrect, replace |

|

|

| TS244/TD244 circuit. |

| to amplifier terminals 4 & 5. |

| The T244,TS244/TD244 or |

|

|

|

|

| Set T244 or TD244 to max- |

| repair wiring. |

|

|

|

|

| imum setting. Measure |

|

|

|

|

|

|

| resistance across wires. |

|

|

|

|

|

|

| Meter should read 6000 |

|

|

|

|

|

|

| ohms ± 1000 (T244). If |

|

|

|

|

|

|

| TS244/TD244 are used, |

|

|

|

|

|

|

| meter should read 4500 |

|

|

|

|

|

|

| ohms ± 1000 (TS244) and |

|

|

|

|

|

|

|

|

| |

|

|

|

|

| 2100 ohms ± 150 (TD244). |

|

|

|

|

|

|

|

|

|

|

Control circuits external to Series 44 can cause burner malfunction. Always check manual valve to be certain gas is on, and check limit controls for normal operation.

14