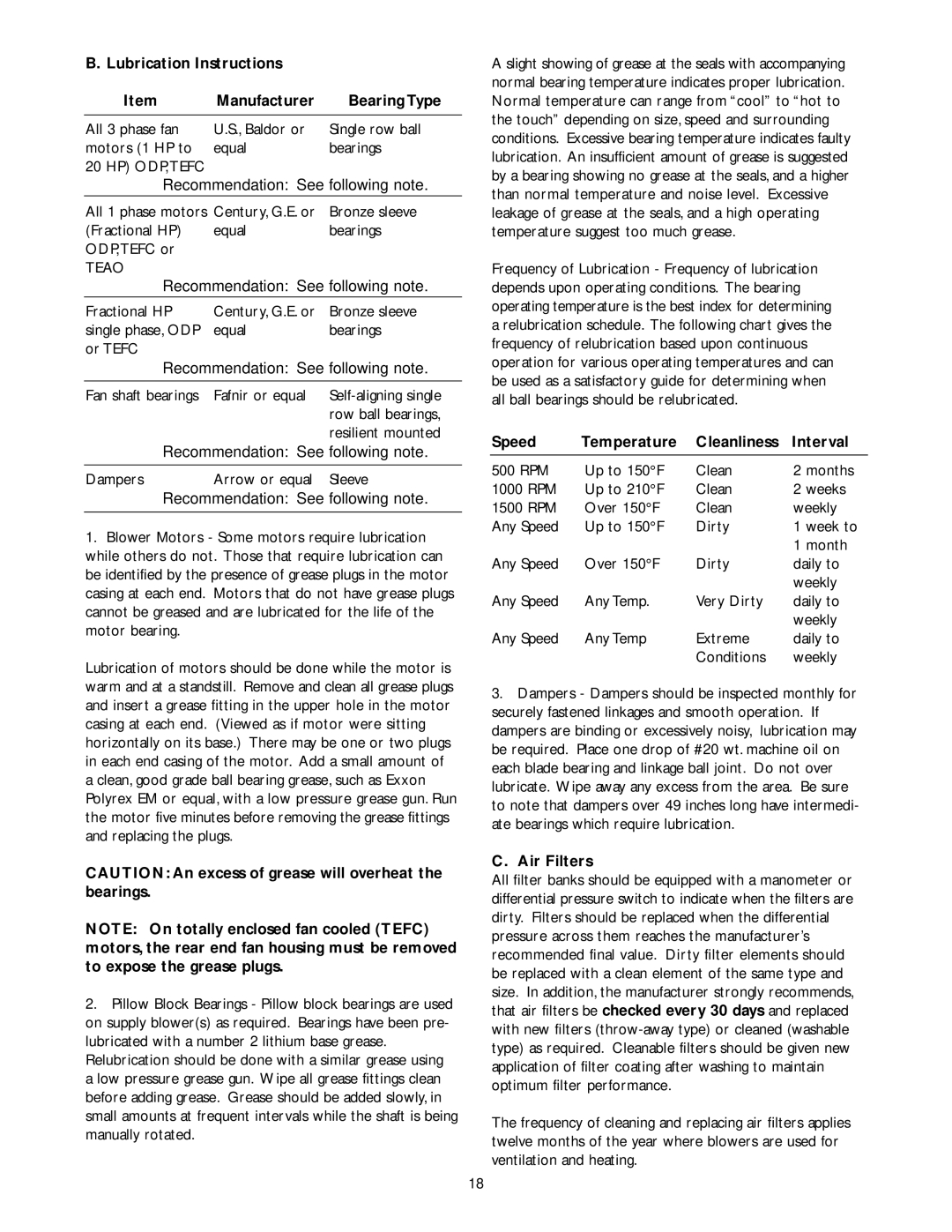

B. Lubrication Instructions |

| |

Item | Manufacturer | Bearing Type |

|

|

|

All 3 phase fan | U.S., Baldor or | Single row ball |

motors (1 HP to | equal | bearings |

20 HP) ODP,TEFC

Recommendation: See following note.

All 1 phase motors | Century, G.E. or | Bronze sleeve |

(Fractional HP) | equal | bearings |

ODP,TEFC or |

|

|

TEAO |

|

|

Recommendation: See following note.

Fractional HP | Century, G.E. or | Bronze sleeve |

single phase, ODP | equal | bearings |

or TEFC |

|

|

Recommendation: See following note. | ||

|

|

|

Fan shaft bearings | Fafnir or equal | |

|

| row ball bearings, |

|

| resilient mounted |

Recommendation: See following note. | ||

|

|

|

Dampers | Arrow or equal | Sleeve |

Recommendation: See following note.

1.Blower Motors - Some motors require lubrication while others do not. Those that require lubrication can be identified by the presence of grease plugs in the motor casing at each end. Motors that do not have grease plugs cannot be greased and are lubricated for the life of the motor bearing.

Lubrication of motors should be done while the motor is warm and at a standstill. Remove and clean all grease plugs and insert a grease fitting in the upper hole in the motor casing at each end. (Viewed as if motor were sitting horizontally on its base.) There may be one or two plugs in each end casing of the motor. Add a small amount of a clean, good grade ball bearing grease, such as Exxon Polyrex EM or equal, with a low pressure grease gun. Run the motor five minutes before removing the grease fittings and replacing the plugs.

CAUTION: An excess of grease will overheat the bearings.

NOTE: On totally enclosed fan cooled (TEFC) motors, the rear end fan housing must be removed to expose the grease plugs.

2.Pillow Block Bearings - Pillow block bearings are used on supply blower(s) as required. Bearings have been pre- lubricated with a number 2 lithium base grease.

Relubrication should be done with a similar grease using a low pressure grease gun. Wipe all grease fittings clean before adding grease. Grease should be added slowly, in small amounts at frequent intervals while the shaft is being manually rotated.

A slight showing of grease at the seals with accompanying normal bearing temperature indicates proper lubrication. Normal temperature can range from “cool” to “hot to the touch” depending on size, speed and surrounding conditions. Excessive bearing temperature indicates faulty lubrication. An insufficient amount of grease is suggested by a bearing showing no grease at the seals, and a higher than normal temperature and noise level. Excessive leakage of grease at the seals, and a high operating temperature suggest too much grease.

Frequency of Lubrication - Frequency of lubrication depends upon operating conditions. The bearing operating temperature is the best index for determining a relubrication schedule. The following chart gives the frequency of relubrication based upon continuous operation for various operating temperatures and can be used as a satisfactory guide for determining when all ball bearings should be relubricated.

Speed | Temperature | Cleanliness | Interval |

500 RPM | Up to 150°F | Clean | 2 months |

1000 RPM | Up to 210°F | Clean | 2 weeks |

1500 RPM | Over 150°F | Clean | weekly |

Any Speed | Up to 150°F | Dirty | 1 week to |

|

|

| 1 month |

Any Speed | Over 150°F | Dirty | daily to |

|

|

| weekly |

Any Speed | Any Temp. | Very Dirty | daily to |

|

|

| weekly |

Any Speed | Any Temp | Extreme | daily to |

|

| Conditions | weekly |

3.Dampers - Dampers should be inspected monthly for securely fastened linkages and smooth operation. If dampers are binding or excessively noisy, lubrication may be required. Place one drop of #20 wt. machine oil on each blade bearing and linkage ball joint. Do not over lubricate. Wipe away any excess from the area. Be sure to note that dampers over 49 inches long have intermedi- ate bearings which require lubrication.

C. Air Filters

All filter banks should be equipped with a manometer or differential pressure switch to indicate when the filters are dirty. Filters should be replaced when the differential pressure across them reaches the manufacturer’s recommended final value. Dirty filter elements should be replaced with a clean element of the same type and size. In addition, the manufacturer strongly recommends, that air filters be checked every 30 days and replaced with new filters

The frequency of cleaning and replacing air filters applies twelve months of the year where blowers are used for ventilation and heating.

18