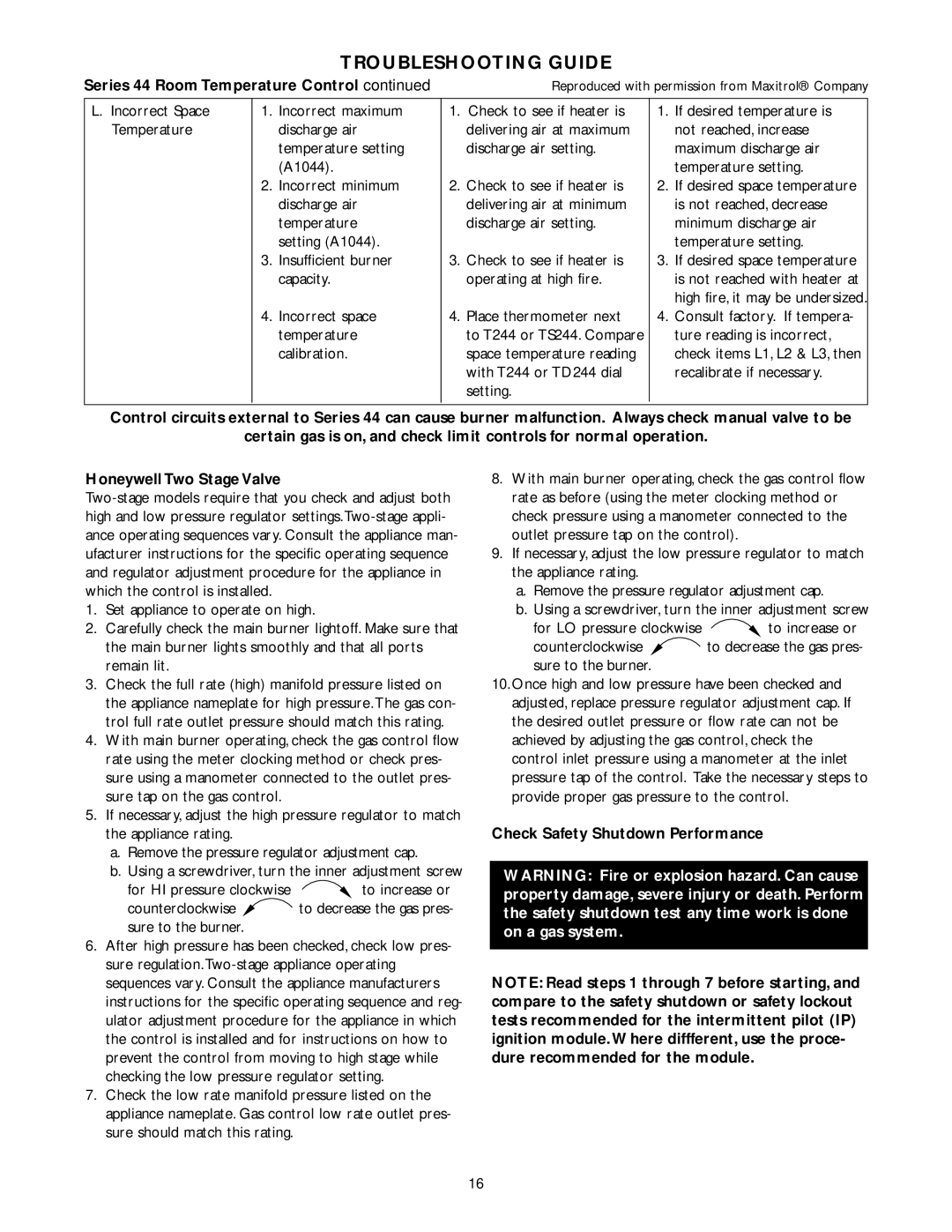

TROUBLESHOOTING GUIDE

Series 44 Room Temperature Control continued |

| Reproduced with permission from Maxitrol® Company | ||||

L. Incorrect Space | 1. | Incorrect maximum | 1. | Check to see if heater is | 1. | If desired temperature is |

Temperature |

| discharge air |

| delivering air at maximum |

| not reached, increase |

|

| temperature setting |

| discharge air setting. |

| maximum discharge air |

|

| (A1044). |

|

|

| temperature setting. |

| 2. | Incorrect minimum | 2. | Check to see if heater is | 2. | If desired space temperature |

|

| discharge air |

| delivering air at minimum |

| is not reached, decrease |

|

| temperature |

| discharge air setting. |

| minimum discharge air |

|

| setting (A1044). |

|

|

| temperature setting. |

| 3. | Insufficient burner | 3. | Check to see if heater is | 3. | If desired space temperature |

|

| capacity. |

| operating at high fire. |

| is not reached with heater at |

|

|

|

|

|

| high fire, it may be undersized. |

| 4. | Incorrect space | 4. | Place thermometer next | 4. | Consult factory. If tempera- |

|

| temperature |

| to T244 or TS244. Compare |

| ture reading is incorrect, |

|

| calibration. |

| space temperature reading |

| check items L1, L2 & L3, then |

|

|

|

| with T244 or TD244 dial |

| recalibrate if necessary. |

|

|

|

| setting. |

|

|

|

|

|

|

|

|

|

Control circuits external to Series 44 can cause burner malfunction. Always check manual valve to be certain gas is on, and check limit controls for normal operation.

Honeywell Two Stage Valve

1.Set appliance to operate on high.

2.Carefully check the main burner lightoff. Make sure that the main burner lights smoothly and that all ports remain lit.

3.Check the full rate (high) manifold pressure listed on the appliance nameplate for high pressure.The gas con- trol full rate outlet pressure should match this rating.

4.With main burner operating, check the gas control flow rate using the meter clocking method or check pres- sure using a manometer connected to the outlet pres- sure tap on the gas control.

5.If necessary, adjust the high pressure regulator to match the appliance rating.

a.Remove the pressure regulator adjustment cap.

b.Using a screwdriver, turn the inner adjustment screw

for HI pressure clockwise ![]() to increase or

to increase or

counterclockwise ![]() to decrease the gas pres- sure to the burner.

to decrease the gas pres- sure to the burner.

6.After high pressure has been checked, check low pres- sure

7.Check the low rate manifold pressure listed on the appliance nameplate. Gas control low rate outlet pres- sure should match this rating.

8.With main burner operating, check the gas control flow rate as before (using the meter clocking method or check pressure using a manometer connected to the outlet pressure tap on the control).

9.If necessary, adjust the low pressure regulator to match the appliance rating.

a.Remove the pressure regulator adjustment cap.

b.Using a screwdriver, turn the inner adjustment screw

for LO pressure clockwise ![]() to increase or

to increase or

counterclockwise ![]() to decrease the gas pres- sure to the burner.

to decrease the gas pres- sure to the burner.

10.Once high and low pressure have been checked and adjusted, replace pressure regulator adjustment cap. If the desired outlet pressure or flow rate can not be achieved by adjusting the gas control, check the control inlet pressure using a manometer at the inlet pressure tap of the control. Take the necessary steps to provide proper gas pressure to the control.

Check Safety Shutdown Performance

WARNING: Fire or explosion hazard. Can cause property damage, severe injury or death. Perform the safety shutdown test any time work is done on a gas system.

NOTE: Read steps 1 through 7 before starting, and compare to the safety shutdown or safety lockout tests recommended for the intermittent pilot (IP) ignition module.Where diffferent, use the proce- dure recommended for the module.

16