United Technologies Electronics Controls

Operation of the Series

Ignition Control

On a call for heat a five second

If ignition is not achieved within 15 seconds, the control shuts off the gas and locks out. If the trial for ignition has been accomplished without ignition, the control shuts off

all outputs and enters lockout. Reset is accomplished by cycling the power off for a minimum of 5 seconds.

If flame is lost once it has been established, the control will shut off the gas valve within 0.8 seconds and locks out.

If flame is sensed during a purge period when no flame should be present, the control will remain in purge with the gas valve off until the false flame disappears.

If the gas valve is found to be powered when it should be off, or not powered when it should be on, the control will enter lockout with all outputs off. Reset is accomplished by cycling the power off for a minimum of 5 seconds.

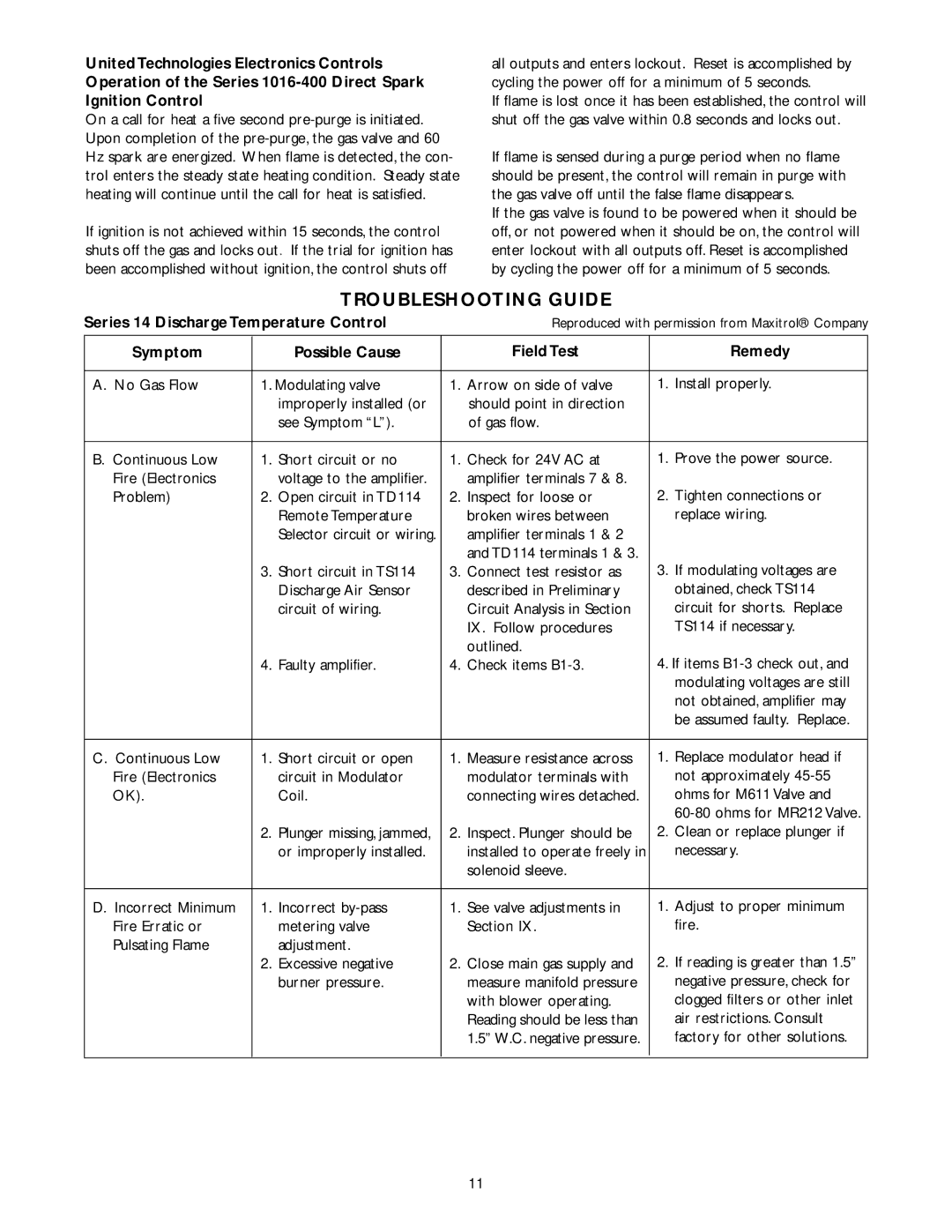

TROUBLESHOOTING GUIDE

Series 14 Discharge Temperature Control |

| Reproduced with permission from Maxitrol® Company | |||||

Symptom |

|

| Possible Cause |

| Field Test |

| Remedy |

|

|

|

|

|

|

| |

A. No Gas Flow |

|

|

| 1. | Arrow on side of valve | 1. | Install properly. |

1. Modulating valve | |||||||

|

|

| improperly installed (or |

| should point in direction |

|

|

|

|

| see Symptom “L”). |

| of gas flow. |

|

|

|

|

|

|

|

|

|

|

B. Continuous Low |

| 1. | Short circuit or no | 1. | Check for 24V AC at | 1. | Prove the power source. |

Fire (Electronics |

|

| voltage to the amplifier. |

| amplifier terminals 7 & 8. | 2. | Tighten connections or |

Problem) |

| 2. | Open circuit in TD114 | 2. | Inspect for loose or | ||

|

|

| Remote Temperature |

| broken wires between |

| replace wiring. |

|

|

| Selector circuit or wiring. |

| amplifier terminals 1 & 2 |

|

|

|

|

|

|

| and TD114 terminals 1 & 3. | 3. | If modulating voltages are |

|

| 3. | Short circuit in TS114 | 3. | Connect test resistor as | ||

|

|

| Discharge Air Sensor |

| described in Preliminary |

| obtained, check TS114 |

|

|

| circuit of wiring. |

| Circuit Analysis in Section |

| circuit for shorts. Replace |

|

|

|

|

| IX. Follow procedures |

| TS114 if necessary. |

|

|

|

|

| outlined. | 4. If items | |

|

| 4. | Faulty amplifier. | 4. | Check items | ||

|

|

|

|

|

|

| modulating voltages are still |

|

|

|

|

|

|

| not obtained, amplifier may |

|

|

|

|

|

|

| be assumed faulty. Replace. |

|

|

|

|

|

|

|

|

C. Continuous Low |

| 1. | Short circuit or open | 1. | Measure resistance across | 1. | Replace modulator head if |

Fire (Electronics |

|

| circuit in Modulator |

| modulator terminals with |

| not approximately |

OK). |

|

| Coil. |

| connecting wires detached. |

| ohms for M611 Valve and |

|

|

|

|

|

|

| |

|

| 2. | Plunger missing, jammed, | 2. | Inspect. Plunger should be | 2. | Clean or replace plunger if |

|

|

| or improperly installed. |

| installed to operate freely in |

| necessary. |

|

|

|

|

| solenoid sleeve. |

|

|

|

|

|

|

|

|

|

|

D. Incorrect Minimum |

| 1. | Incorrect | 1. | See valve adjustments in | 1. | Adjust to proper minimum |

Fire Erratic or |

|

| metering valve |

| Section IX. |

| fire. |

Pulsating Flame |

|

| adjustment. |

|

| 2. | If reading is greater than 1.5” |

|

| 2. | Excessive negative | 2. | Close main gas supply and | ||

|

|

| burner pressure. |

| measure manifold pressure |

| negative pressure, check for |

|

|

|

|

| with blower operating. |

| clogged filters or other inlet |

|

|

|

|

| Reading should be less than |

| air restrictions. Consult |

|

|

|

|

| 1.5” W.C. negative pressure. |

| factory for other solutions. |

|

|

|

|

|

|

|

|

11