Shortening Driveline

1.Move cutter up and down to get the shortest possible distance between tractor PTO shaft and gearbox input shaft.

2.Separate driveline into two halves and connect them to the tractor PTO and gearbox.

3.Place driveline halves parallel to one another to determine how much to shorten the driveline.

DP2

Figure 5. Drive Halves Placed Parallel

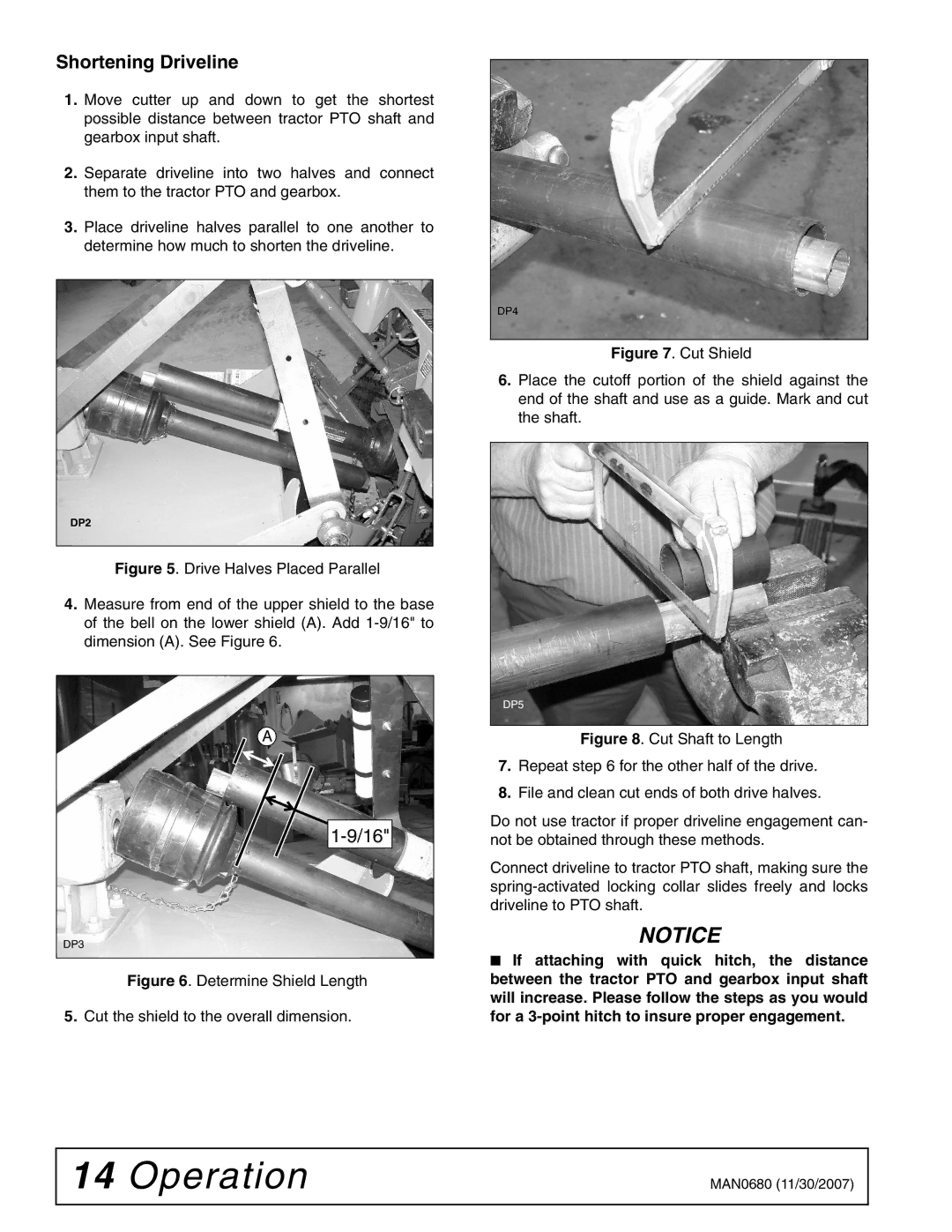

4.Measure from end of the upper shield to the base of the bell on the lower shield (A). Add 1-9/16" to dimension (A). See Figure 6.

A

DP3

Figure 6. Determine Shield Length

5.Cut the shield to the overall dimension.

DP4

Figure 7. Cut Shield

6.Place the cutoff portion of the shield against the end of the shaft and use as a guide. Mark and cut the shaft.

DP5

Figure 8. Cut Shaft to Length

7.Repeat step 6 for the other half of the drive.

8.File and clean cut ends of both drive halves.

Do not use tractor if proper driveline engagement can- not be obtained through these methods.

Connect driveline to tractor PTO shaft, making sure the spring-activated locking collar slides freely and locks driveline to PTO shaft.

NOTICE

■If attaching with quick hitch, the distance between the tractor PTO and gearbox input shaft will increase. Please follow the steps as you would for a

14 Operation | MAN0680 (11/30/2007) |

|

|