ASSEMBLY

DEALER SET-UP INSTRUCTIONS

Assembly of this cutter is the responsibility of the Woods dealer. If should be delivered to the owner com- pletely assembled, lubricated, and adjusted for normal cutting conditions.

Complete Dealer Check Lists, page 34 when you have completed the assembly.

The cutter is shipped partially assembled. Assembly will be easier if aligned and loosely assembled before tightening hardware. Recommended torque values for hardware are located in the Bolt Torque Chart, page 45.

Full chain, rubber, or steel band shielding must be installed when operating in populated areas or other areas where thrown objects could injure peo- ple or damage property.

•If this machine is not equipped with full chain, rubber, or steel band shielding, operation must

be stopped when anyone comes within 300 feet (92 m).

•This shielding is designed to reduce the risk of thrown objects. The mower deck and protec- tive devices cannot prevent all objects from escaping the blade enclosure in every mowing condition. It is possible for objects to ricochet and escape, traveling as much as 300 feet (92 m).

Make sure

Operate tractor PTO at 540 RPM. Do not exceed.

![]() CAUTION

CAUTION

Always wear relatively tight and belted clothing to avoid getting caught in moving parts. Wear sturdy,

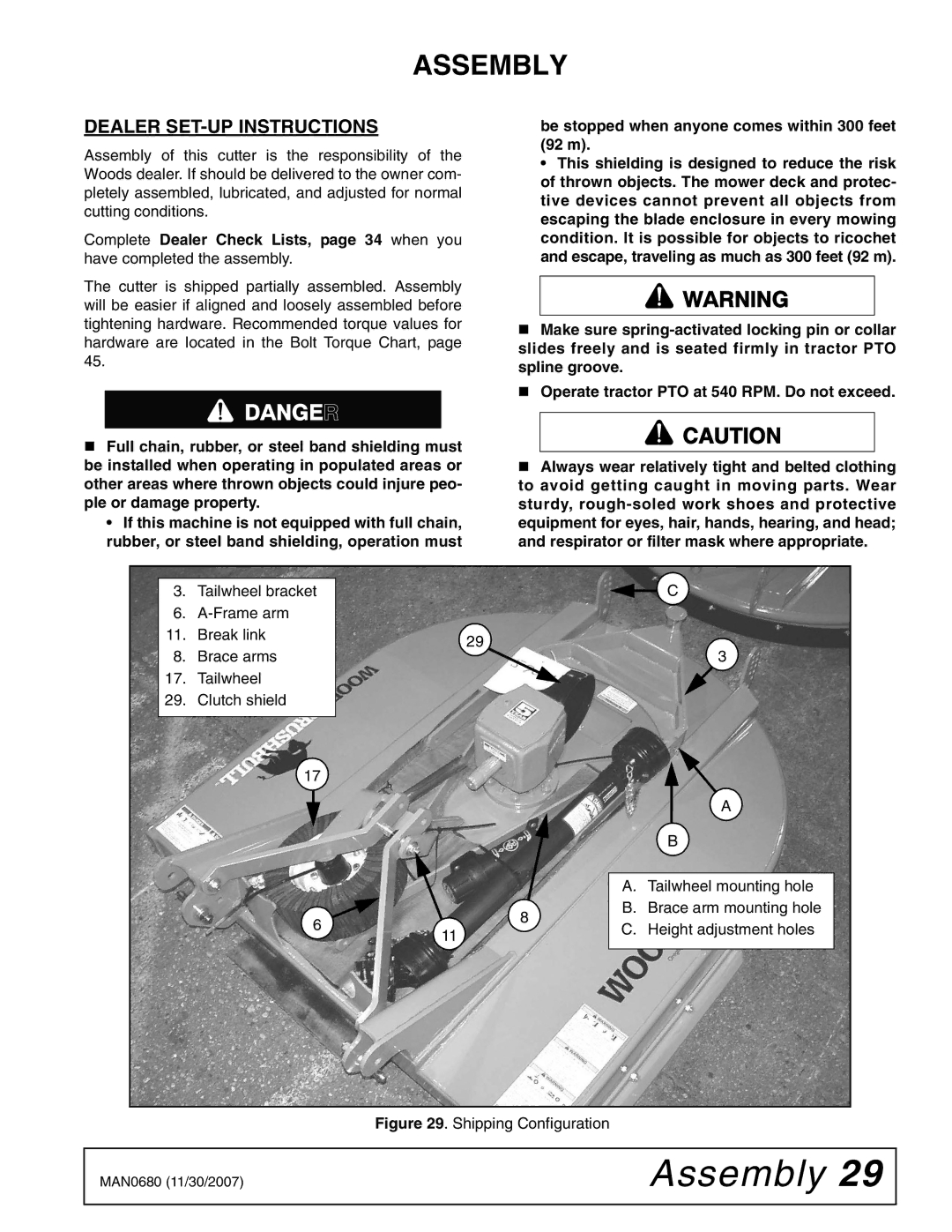

3. Tailwheel bracket

6.

11. Break link

8. Brace arms

17. Tailwheel

29. Clutch shield

17

6

29

8

11

C

3

A

B

A.Tailwheel mounting hole

B.Brace arm mounting hole

C.Height adjustment holes

Figure 29. Shipping Configuration

MAN0680 (11/30/2007) | Assembly 29 |

|

|