REMOVE BROOM FROM SKID STEER

Do not allow bystanders in the area when oper- ating, attaching, removing, assembling, or servic- ing equipment.

Do not disconnect hydraulic lines until all sys- tem pressure is relieved. Lower unit to ground, stop engine, and operate all hydraulic control levers.

On a hard level surface, lower attachment to the ground.

Shut off engine, set brake, remove key, remove seat belt, and release operator restraint before leaving the skid steer operator's seat.

Disconnect hydraulic hoses from quick couplers. Install dust plugs and couple hoses together for storage.

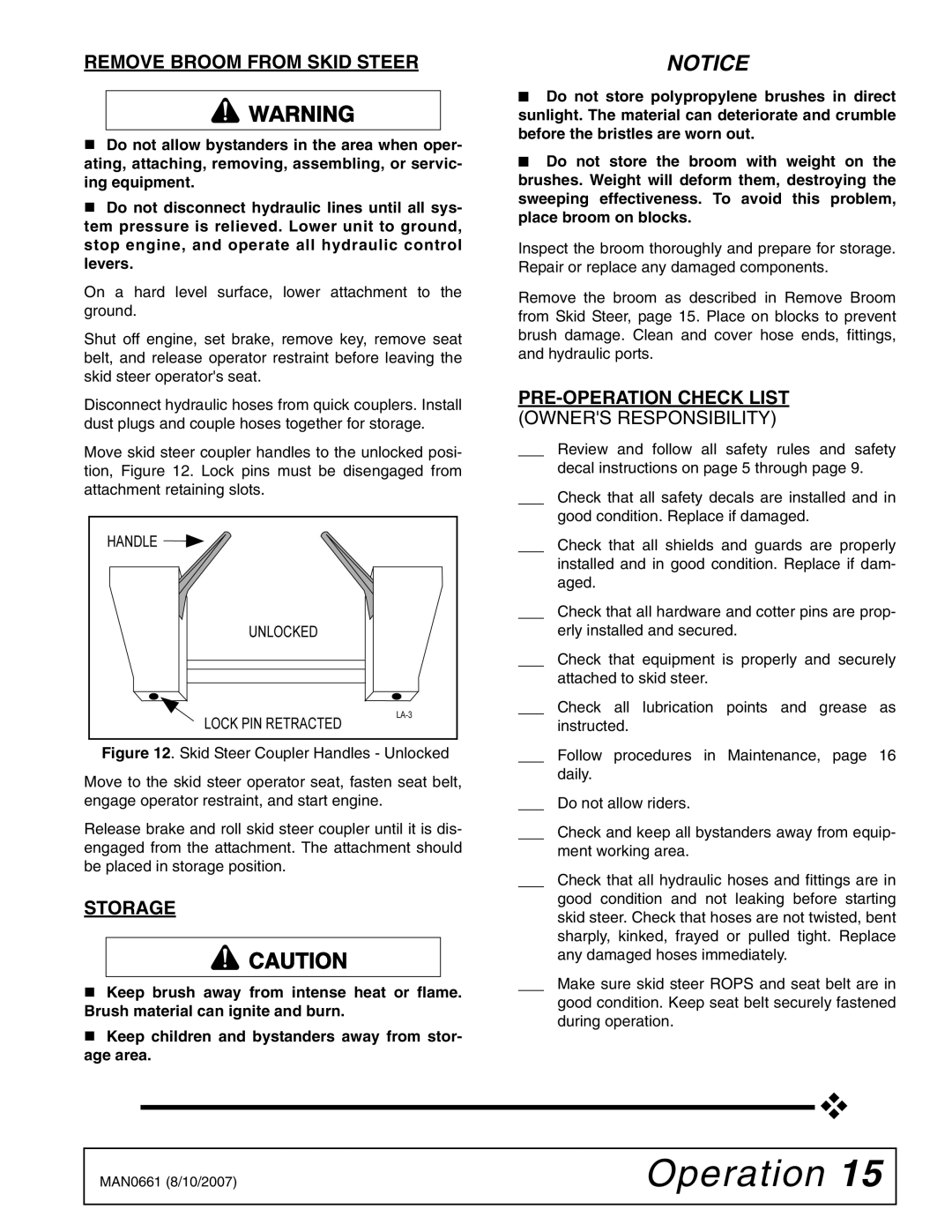

Move skid steer coupler handles to the unlocked posi- tion, Figure 12. Lock pins must be disengaged from attachment retaining slots.

Figure 12. Skid Steer Coupler Handles - Unlocked

Move to the skid steer operator seat, fasten seat belt, engage operator restraint, and start engine.

Release brake and roll skid steer coupler until it is dis- engaged from the attachment. The attachment should be placed in storage position.

STORAGE

![]() CAUTION

CAUTION

Keep brush away from intense heat or flame. Brush material can ignite and burn.

Keep children and bystanders away from stor- age area.

NOTICE

■Do not store polypropylene brushes in direct sunlight. The material can deteriorate and crumble before the bristles are worn out.

■Do not store the broom with weight on the brushes. Weight will deform them, destroying the sweeping effectiveness. To avoid this problem, place broom on blocks.

Inspect the broom thoroughly and prepare for storage. Repair or replace any damaged components.

Remove the broom as described in Remove Broom from Skid Steer, page 15. Place on blocks to prevent brush damage. Clean and cover hose ends, fittings, and hydraulic ports.

PRE-OPERATION CHECK LIST

(OWNER'S RESPONSIBILITY)

___ Review and follow all safety rules and safety decal instructions on page 5 through page 9.

___ Check that all safety decals are installed and in good condition. Replace if damaged.

___ Check that all shields and guards are properly installed and in good condition. Replace if dam- aged.

___ Check that all hardware and cotter pins are prop- erly installed and secured.

___ Check that equipment is properly and securely attached to skid steer.

___ Check all lubrication | points and grease | as | |

| instructed. |

|

|

___ Follow procedures in | Maintenance, page | 16 | |

| daily. |

|

|

___ | Do not allow riders. |

|

|

___ | Check and keep all bystanders away from equip- | ||

| ment working area. |

|

|

___ Check that all hydraulic hoses and fittings are in good condition and not leaking before starting skid steer. Check that hoses are not twisted, bent sharply, kinked, frayed or pulled tight. Replace any damaged hoses immediately.

___ Make sure skid steer ROPS and seat belt are in good condition. Keep seat belt securely fastened during operation.

MAN0661 (8/10/2007) | Operation 15 |

|

|