M1048 10" x 18" Metal Cutting Bandsaw

Moving & Placing Unit

The Model M1048 comes with lifting brackets installed on the base. Use a forklift and straps rated for the machine weight to lift the machine off the pallet and onto a suit- able location (see Figure 8). The lifting brackets can be removed and saved for future use.

Figure 8. M1048 lifting points.

Shipping Bracket

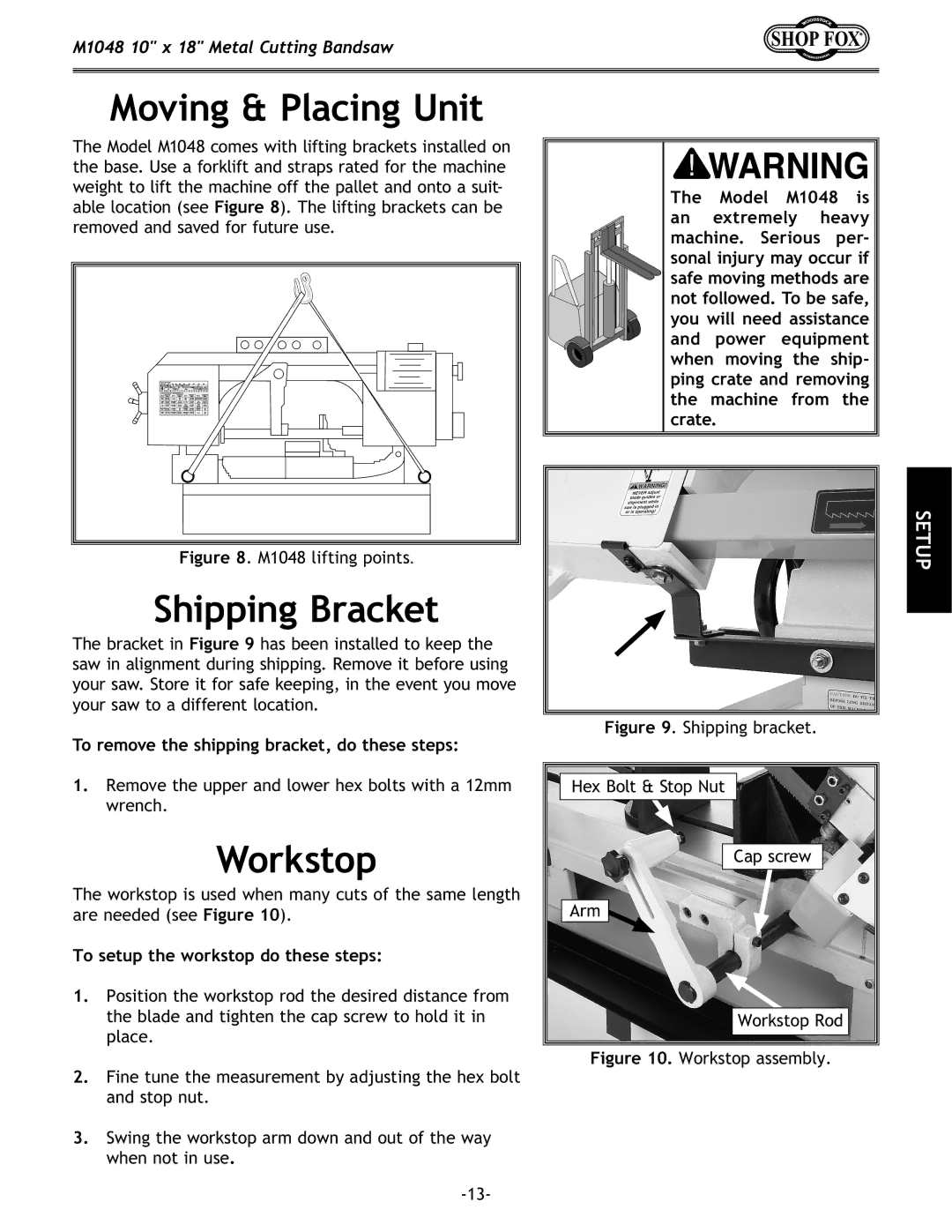

The bracket in Figure 9 has been installed to keep the saw in alignment during shipping. Remove it before using your saw. Store it for safe keeping, in the event you move your saw to a different location.

To remove the shipping bracket, do these steps:

The Model M1048 is an extremely heavy machine. Serious per- sonal injury may occur if safe moving methods are not followed. To be safe, you will need assistance and power equipment when moving the ship- ping crate and removing the machine from the crate.

Figure 9. Shipping bracket.

SETUP

1. Remove the upper and lower hex bolts with a 12mm | Hex Bolt & Stop Nut | |

| wrench. |

|

| Workstop | Cap screw |

|

| |

The workstop is used when many cuts of the same length | Arm | |

are needed (see Figure 10). | ||

To setup the workstop do these steps: |

| |

1. | Position the workstop rod the desired distance from |

|

| the blade and tighten the cap screw to hold it in | Workstop Rod |

| place. | |

|

| |