M1048 10" x 18" Metal Cutting Bandsaw

Squaring Blade to Table

This adjustment has been made at the factory and should not need to be adjusted under normal circumstances. However, if you find the saw is not cutting square, you may need to adjust the blade. Only make this adjustment after factors such as excessive feed rate or the blade guide being set too far away from the workpiece have been ruled out.

To square the blade the to the table, do these steps:

1.DISCONNECT THE BANDSAW FROM POWER!

2.Examine your workpiece for clues as to which way the blade is twisted, or set up a machinist square on the table and blade as shown in Figure 39.

3.Check for gaps along several points of the blade length between the two blade guides. Set the machinist square between the blade teeth for a more accurate reading.

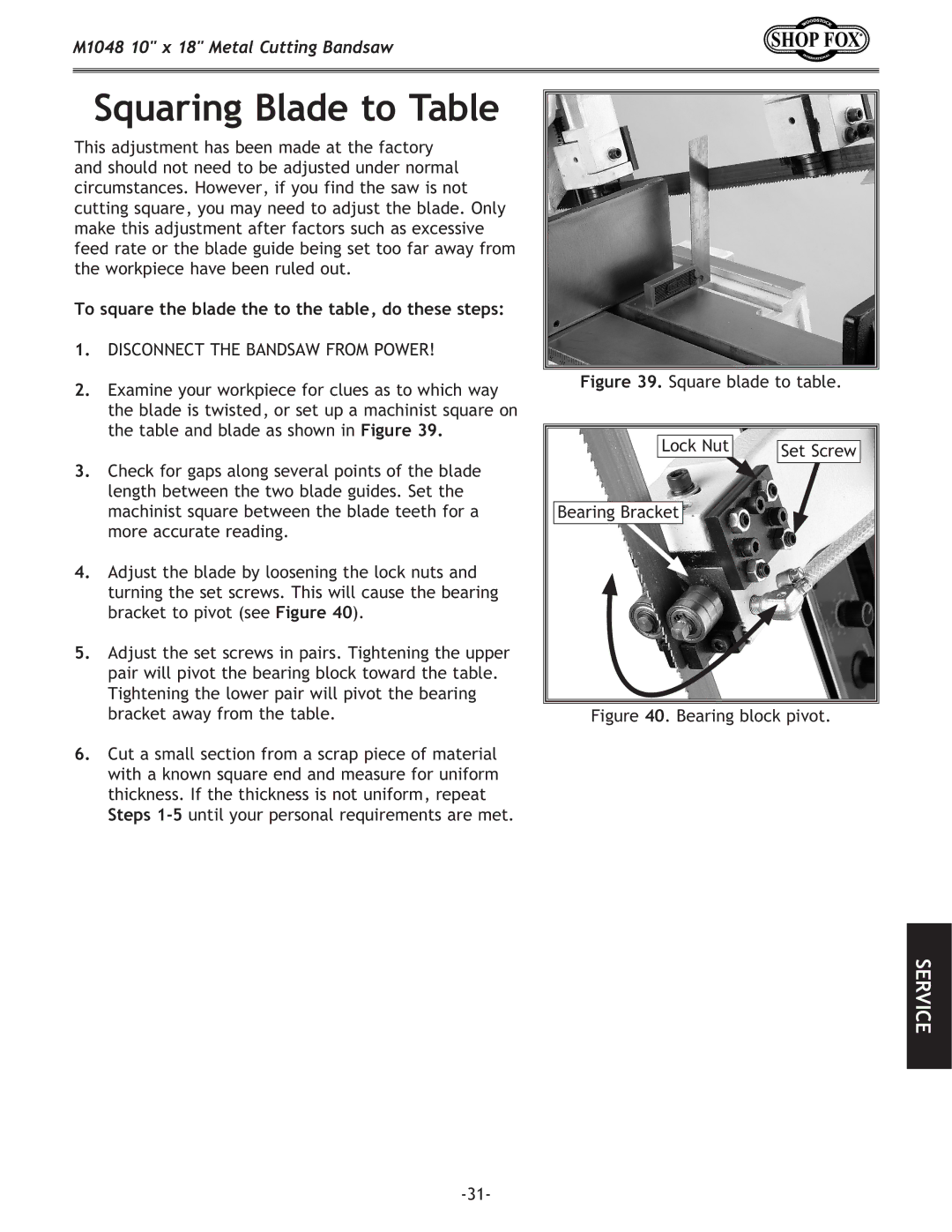

4.Adjust the blade by loosening the lock nuts and turning the set screws. This will cause the bearing bracket to pivot (see Figure 40).

5.Adjust the set screws in pairs. Tightening the upper pair will pivot the bearing block toward the table. Tightening the lower pair will pivot the bearing bracket away from the table.

Figure 39. Square blade to table.

Lock Nut | Set Screw |

| |

Bearing Bracket |

|

Figure 40. Bearing block pivot.

6.Cut a small section from a scrap piece of material with a known square end and measure for uniform thickness. If the thickness is not uniform, repeat Steps 1-5 until your personal requirements are met.

SERVICE