M1048 10" x 18" Metal Cutting Bandsaw

4.Look for the following signs to determine the best feed rate setting for your workpiece.

•If you get warn

•Blue looking chips are from extreme heat caused by high blade speed.

•Thin

•The best cut and feed rate will give you evenly shaped

Coolant System

This bandsaw has a

See Cutting Fluid on Page 22 for additional information. To use the coolant system do these steps:

1.Access the reservoir by removing the rear panel on the base (see Figure 24).

2.Thoroughly clean and remove any foreign material that may have fallen inside the reservoir during ship- ping.

3.Fill the reservoir with your chosen cutting fluid solu- tion and replace the rear panel.

4.Make sure the coolant control valve is turned OFF.

5.Turn the coolant pump switch ON before making your cut.

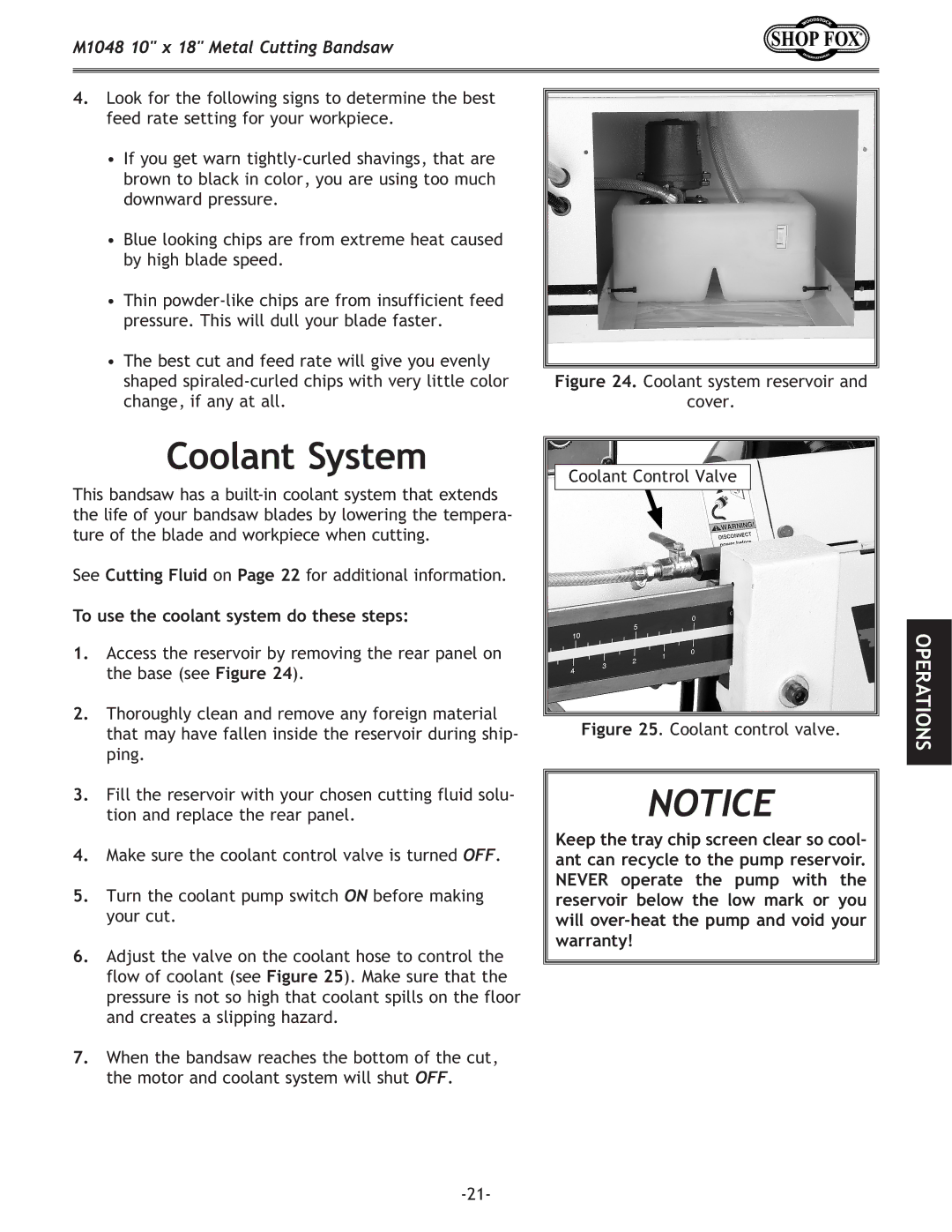

6.Adjust the valve on the coolant hose to control the flow of coolant (see Figure 25). Make sure that the pressure is not so high that coolant spills on the floor and creates a slipping hazard.

7.When the bandsaw reaches the bottom of the cut, the motor and coolant system will shut OFF.

Figure 24. Coolant system reservoir and

cover.

Coolant Control Valve

Figure 25. Coolant control valve.

NOTICE

Keep the tray chip screen clear so cool- ant can recycle to the pump reservoir. NEVER operate the pump with the reservoir below the low mark or you will