E. PARALLELISM

If your table saw has been properly adjusted, the saw blade should be parallel to the miter slot. If your blade and miter slot are not parallel, refer to your table saw manual to adjust the saw blade to the miter slot correctly. Disconnect all electrical power to the table saw and follow all safety rules before you make any adjustments to your table saw.

Align the front edge of the fence to the front edge of the miter slot. Check to see if the fence is paral- lel along the length of the miter slot.

Adjusting the fence parallel to the miter slot is somewhat misleading in that it should not be adjusted perfectly in line. The back end of the fence should fall away from the miter slot approx- imately 1⁄64" so the workpiece clears the opposite end of the saw blade without binding. Figure 17. This is called “lead” (pronounced leed). You don’t have enough lead if there is “feather” or burning on the wood as it is being cut.

CAUTION: DO NOT cut from the right side of the fence if lead was adjusted for cutting on the left side of the fence. The wood will pinch and could cause dangerous

To adjust the fence to the miter slot:

Step 1.

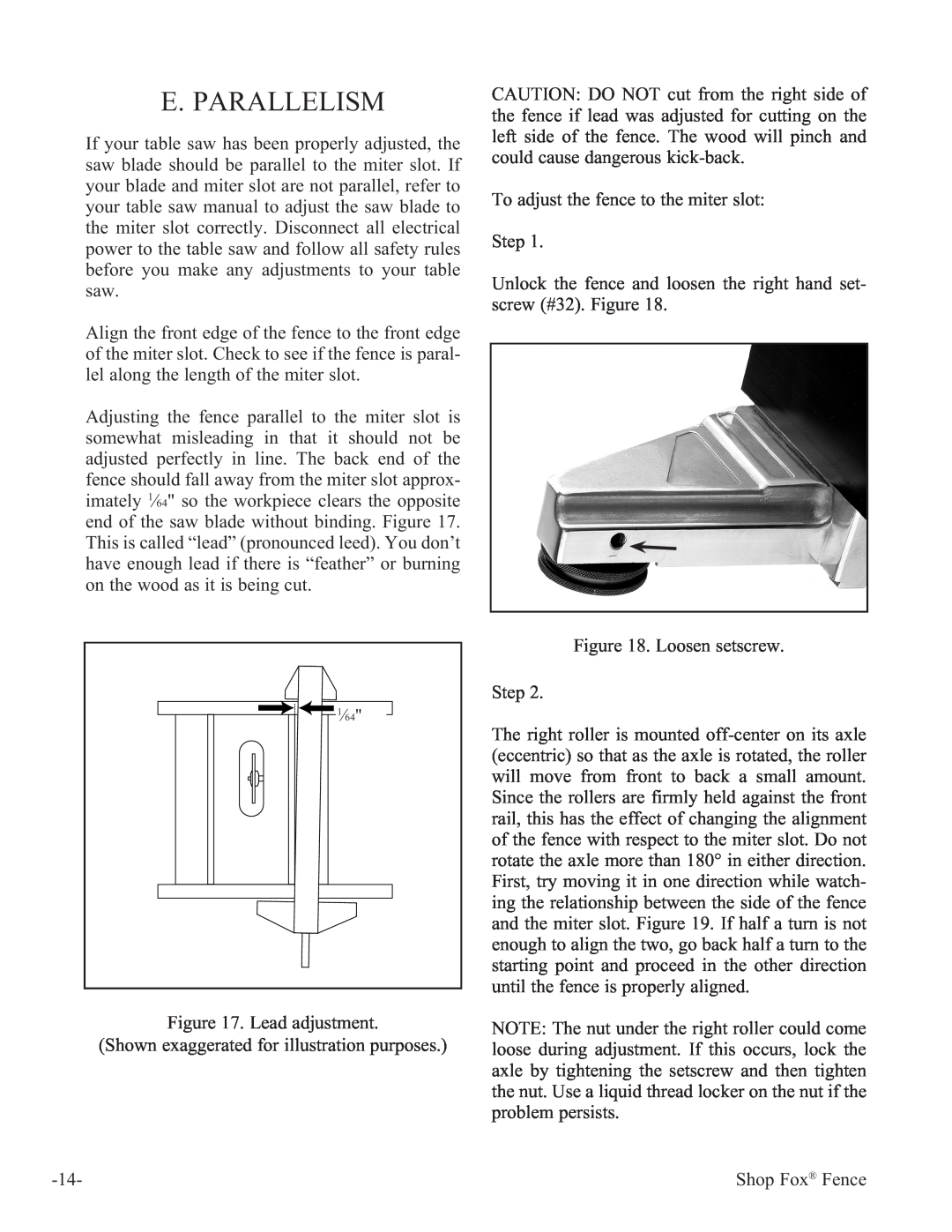

Unlock the fence and loosen the right hand set- screw (#32). Figure 18.

![]()

![]()

![]() 1⁄64"

1⁄64"

Figure 17. Lead adjustment.

(Shown exaggerated for illustration purposes.)

Figure 18. Loosen setscrew.

Step 2.

The right roller is mounted

NOTE: The nut under the right roller could come loose during adjustment. If this occurs, lock the axle by tightening the setscrew and then tighten the nut. Use a liquid thread locker on the nut if the problem persists.

Shop Fox® Fence |