OPERATIONS

Operation Musts

•Never allow hands or push blocks to come within 4" of the cutterhead while it is mov- ing.

•Carefully inspect any lumber that you plan to run through the jointer. Some defects such as moderate twisting, loose knots or severe cracks may make the stock unusable.

•Only use clean stock. See Figure 33. Remove all dirt, nails, staples, imbedded gravel, etc. from any lumber you plan on using. A hidden nail in a workpiece will instantly damage the sharp edges of the knives. This will cause unsatisfactory results in future operations.

•Use ONLY natural wood fiber. Never use wood composites such as particle board, plywood or MDF. Also, never use laminates, formica or other synthetic materials.

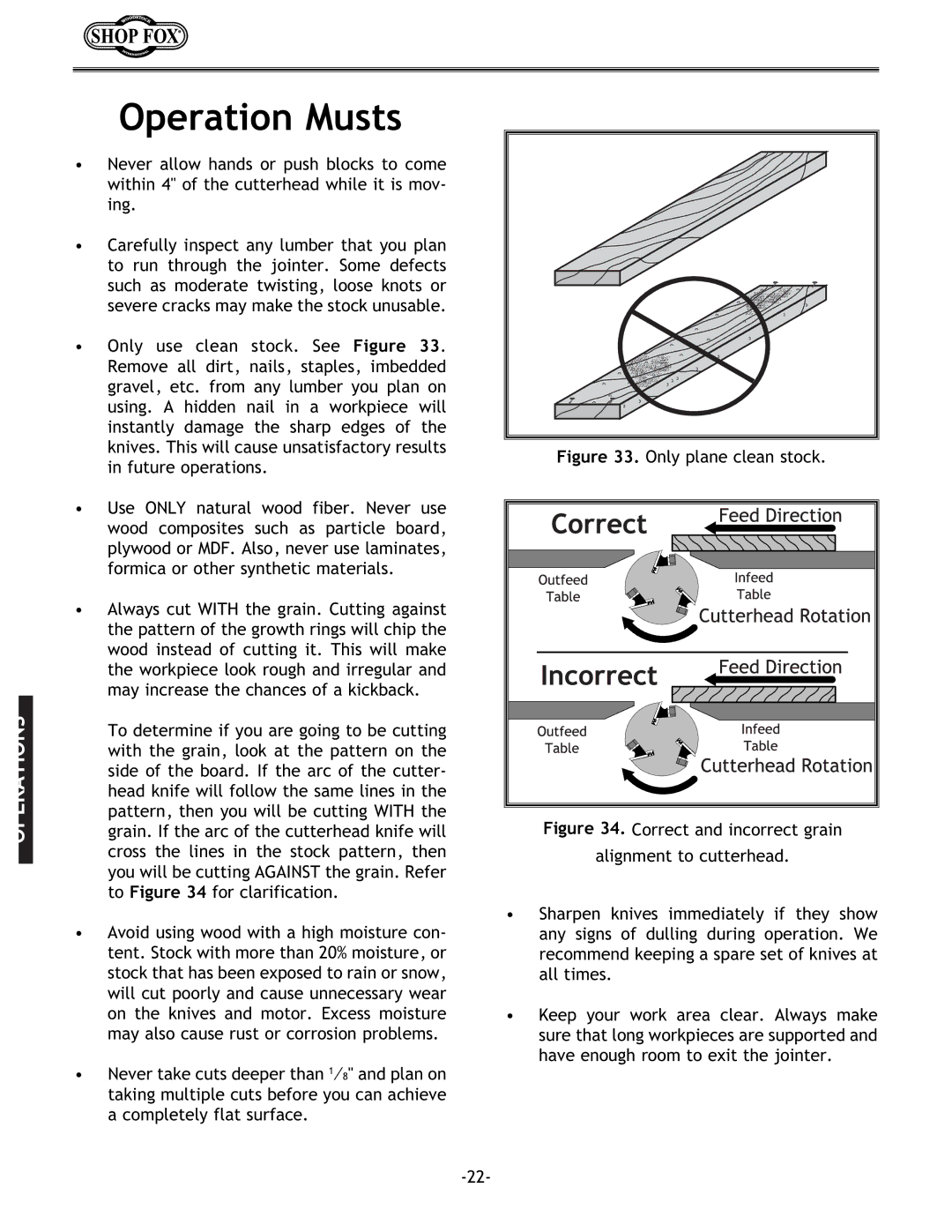

•Always cut WITH the grain. Cutting against the pattern of the growth rings will chip the wood instead of cutting it. This will make the workpiece look rough and irregular and may increase the chances of a kickback.

To determine if you are going to be cutting with the grain, look at the pattern on the side of the board. If the arc of the cutter- head knife will follow the same lines in the pattern, then you will be cutting WITH the grain. If the arc of the cutterhead knife will cross the lines in the stock pattern, then you will be cutting AGAINST the grain. Refer to Figure 34 for clarification.

•Avoid using wood with a high moisture con- tent. Stock with more than 20% moisture, or stock that has been exposed to rain or snow, will cut poorly and cause unnecessary wear on the knives and motor. Excess moisture may also cause rust or corrosion problems.

•Never take cuts deeper than 1⁄8" and plan on taking multiple cuts before you can achieve a completely flat surface.