Portion |

Removed With |

Jointer |

Figure 39. Bevel cutting produces an

angled edge.

Always wear safety glasses to prevent seri- ous personal injury!

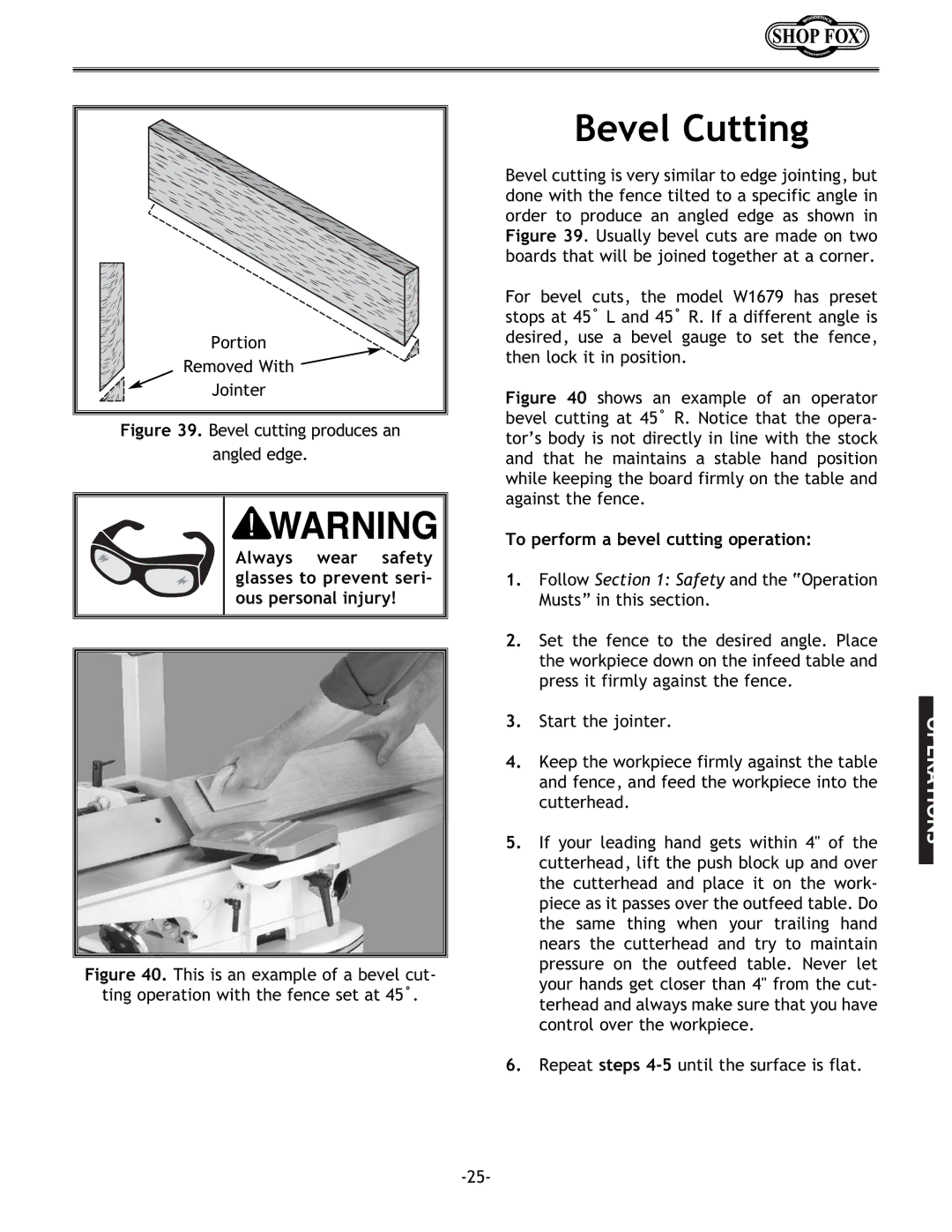

Figure 40. This is an example of a bevel cut- ting operation with the fence set at 45˚.

Bevel Cutting

Bevel cutting is very similar to edge jointing, but done with the fence tilted to a specific angle in order to produce an angled edge as shown in Figure 39. Usually bevel cuts are made on two boards that will be joined together at a corner.

For bevel cuts, the model W1679 has preset stops at 45˚ L and 45˚ R. If a different angle is desired, use a bevel gauge to set the fence, then lock it in position.

Figure 40 shows an example of an operator bevel cutting at 45˚ R. Notice that the opera- tor’s body is not directly in line with the stock and that he maintains a stable hand position while keeping the board firmly on the table and against the fence.

To perform a bevel cutting operation:

1.Follow Section 1: Safety and the “Operation Musts” in this section.

2.Set the fence to the desired angle. Place the workpiece down on the infeed table and press it firmly against the fence.

3.Start the jointer.

4.Keep the workpiece firmly against the table and fence, and feed the workpiece into the cutterhead.

5.If your leading hand gets within 4" of the cutterhead, lift the push block up and over the cutterhead and place it on the work- piece as it passes over the outfeed table. Do the same thing when your trailing hand nears the cutterhead and try to maintain pressure on the outfeed table. Never let your hands get closer than 4" from the cut- terhead and always make sure that you have control over the workpiece.

6.Repeat steps

OPERATIONS