OPERATIONS

Edge Jointing

Edge jointing is passing the workpiece over the jointer on its edge as shown in Figure 37. This process makes the edges of a workpiece per- fectly flat.

Stock must be edge jointed on the concave side. The convex side should then be cut straight with a table saw. This process is commonly used to prepare the workpiece to be

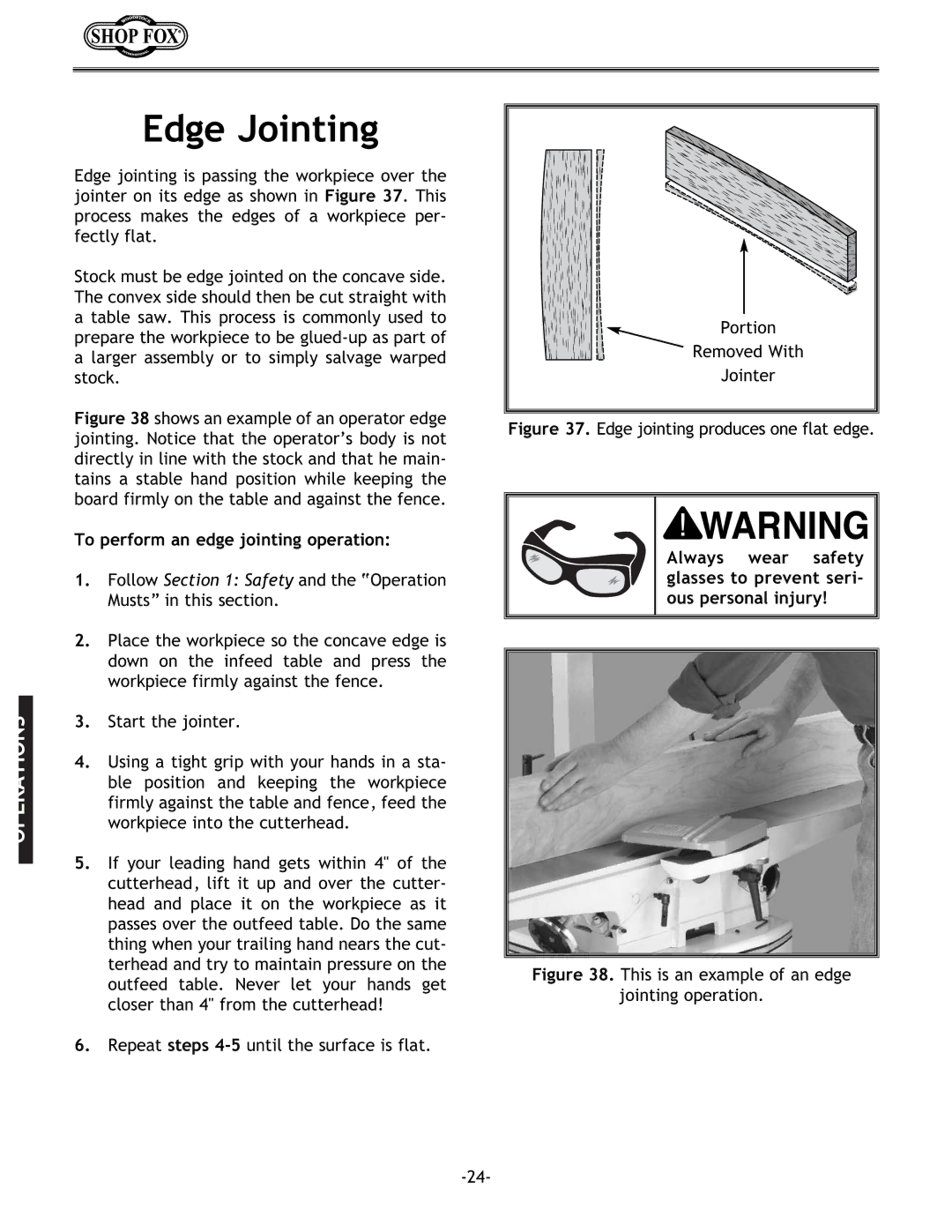

Figure 38 shows an example of an operator edge jointing. Notice that the operator’s body is not directly in line with the stock and that he main- tains a stable hand position while keeping the board firmly on the table and against the fence.

To perform an edge jointing operation:

1.Follow Section 1: Safety and the “Operation Musts” in this section.

2.Place the workpiece so the concave edge is down on the infeed table and press the workpiece firmly against the fence.

3.Start the jointer.

4.Using a tight grip with your hands in a sta- ble position and keeping the workpiece firmly against the table and fence, feed the workpiece into the cutterhead.

5.If your leading hand gets within 4" of the cutterhead, lift it up and over the cutter- head and place it on the workpiece as it passes over the outfeed table. Do the same thing when your trailing hand nears the cut- terhead and try to maintain pressure on the outfeed table. Never let your hands get closer than 4" from the cutterhead!

6.Repeat steps

Portion |

Removed With |

Jointer |

Figure 37. Edge jointing produces one flat edge.

Always wear safety glasses to prevent seri- ous personal injury!