D1NA018, D2NA060 specifications

The York D1NA018 and D2NA060 are advanced rooftop air conditioning units that combine efficiency, reliability, and innovative technologies to provide optimal climate control for commercial buildings. These units are designed to deliver robust performance while ensuring ease of installation and maintenance.The D1NA018 is a compact model with a nominal cooling capacity of 1.5 tons, making it an ideal choice for smaller commercial spaces or applications where space is limited. In contrast, the D2NA060 offers a higher cooling capacity of 5 tons, catering to larger areas or environments that require more substantial cooling solutions. Both units are built with high-quality materials that enhance their durability and extend their operational life.

One of the key features of both models is their energy efficiency. They utilize advanced scroll compressor technology that ensures a quieter operation while optimizing energy consumption. The units are designed to achieve high Seasonal Energy Efficiency Ratios (SEER), which makes them compliant with modern energy regulations. This not only reduces operational costs but also minimizes the environmental impact.

Additionally, the York D1NA018 and D2NA060 come equipped with enhanced airflow technologies. They feature multi-speed blowers that can adapt to varying load conditions, ensuring consistent temperature control throughout the indoor space. The airflow systems are designed to provide even distribution, enhancing comfort for occupants.

These units are also equipped with user-friendly control options. The integrated digital controls allow for precise temperature management and programming, further increasing efficiency. Building managers can easily monitor and control the units, leading to improved operational convenience.

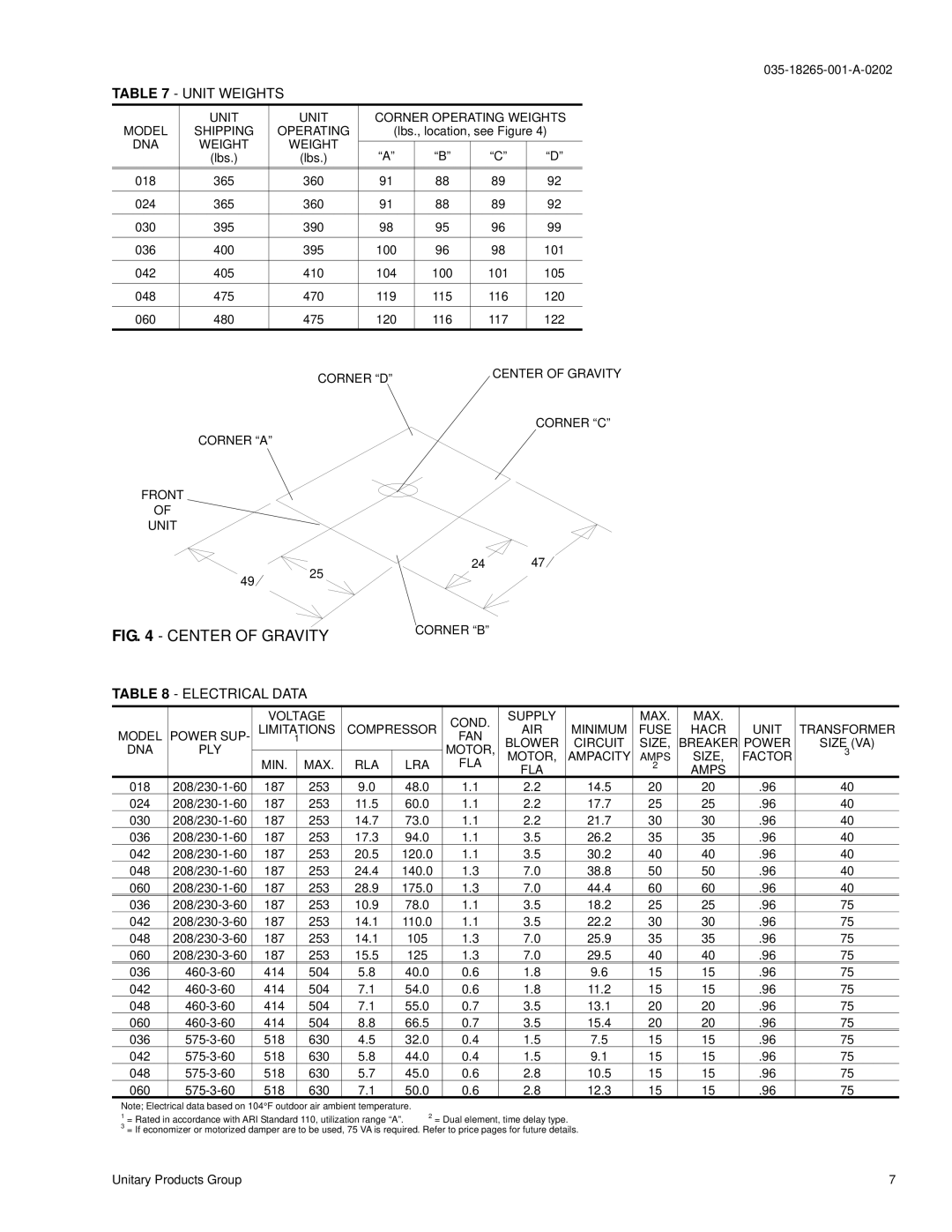

Another standout characteristic is their ease of installation. The compact design and lightweight construction of the D1NA018 simplify rooftop installations. The D2NA060, while larger, maintains a straightforward installation process, ensuring minimal disruption to building operations.

In terms of maintenance, the York D1NA018 and D2NA060 incorporate features that facilitate routine service and upkeep. Access panels are strategically placed, allowing technicians to reach components quickly and perform necessary maintenance checks with ease.

Overall, the York D1NA018 and D2NA060 represent a blend of efficiency, innovation, and practicality, making them suitable choices for a wide range of commercial applications. Their advanced technologies provide reliable climate control while reducing energy consumption, making them a preferred option for businesses seeking sustainable solutions.