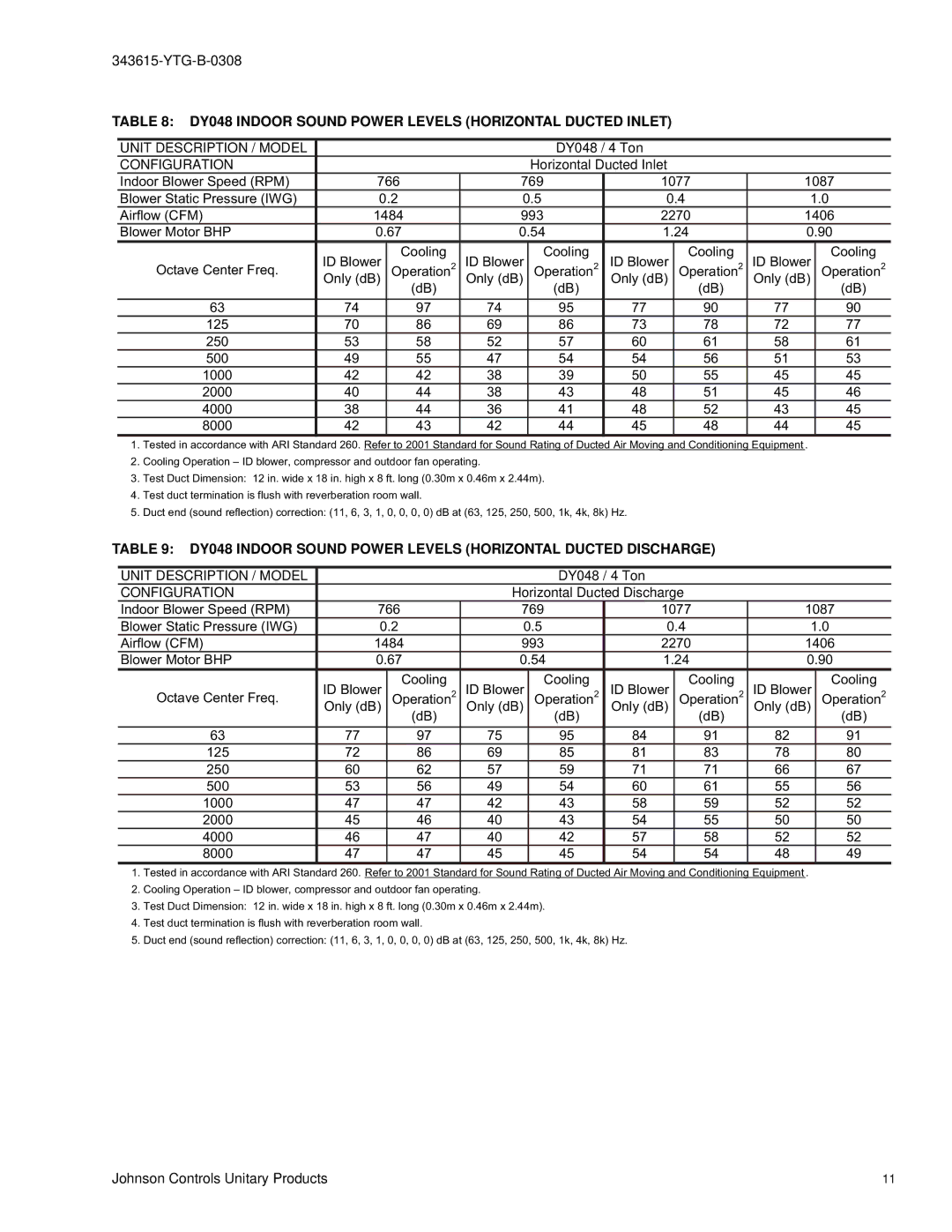

TABLE 8: DY048 INDOOR SOUND POWER LEVELS (HORIZONTAL DUCTED INLET)

UNIT DESCRIPTION / MODEL |

|

|

| DY048 / 4 Ton |

|

|

| ||

CONFIGURATION |

|

|

| Horizontal Ducted Inlet |

|

|

| ||

Indoor Blower Speed (RPM) | 766 | 769 | 1077 | 1087 | |||||

Blower Static Pressure (IWG) | 0.2 | 0.5 | 0.4 | 1.0 | |||||

Airflow (CFM) | 1484 | 993 | 2270 | 1406 | |||||

Blower Motor BHP | 0.67 | 0.54 | 1.24 | 0.90 | |||||

| ID Blower | Cooling | ID Blower | Cooling | ID Blower |

| Cooling | ID Blower | Cooling |

Octave Center Freq. | Operation2 | Operation2 |

| Operation2 | Operation2 | ||||

| Only (dB) | (dB) | Only (dB) | (dB) | Only (dB) |

| (dB) | Only (dB) | (dB) |

|

|

|

|

|

| ||||

63 | 74 | 97 | 74 | 95 | 77 |

| 90 | 77 | 90 |

125 | 70 | 86 | 69 | 86 | 73 |

| 78 | 72 | 77 |

250 | 53 | 58 | 52 | 57 | 60 |

| 61 | 58 | 61 |

500 | 49 | 55 | 47 | 54 | 54 |

| 56 | 51 | 53 |

1000 | 42 | 42 | 38 | 39 | 50 |

| 55 | 45 | 45 |

2000 | 40 | 44 | 38 | 43 | 48 |

| 51 | 45 | 46 |

4000 | 38 | 44 | 36 | 41 | 48 |

| 52 | 43 | 45 |

8000 | 42 | 43 | 42 | 44 | 45 |

| 48 | 44 | 45 |

1.Tested in accordance with ARI Standard 260. Refer to 2001 Standard for Sound Rating of Ducted Air Moving and Conditioning Equipment .

2.Cooling Operation – ID blower, compressor and outdoor fan operating.

3.Test Duct Dimension: 12 in. wide x 18 in. high x 8 ft. long (0.30m x 0.46m x 2.44m).

4.Test duct termination is flush with reverberation room wall.

5.Duct end (sound reflection) correction: (11, 6, 3, 1, 0, 0, 0, 0) dB at (63, 125, 250, 500, 1k, 4k, 8k) Hz.

TABLE 9: DY048 INDOOR SOUND POWER LEVELS (HORIZONTAL DUCTED DISCHARGE)

UNIT DESCRIPTION / MODEL |

|

|

| DY048 / 4 Ton |

|

|

| |

CONFIGURATION |

|

| Horizontal Ducted Discharge |

|

| |||

Indoor Blower Speed (RPM) | 766 | 769 | 1077 | 1087 | ||||

Blower Static Pressure (IWG) | 0.2 | 0.5 | 0.4 | 1.0 | ||||

Airflow (CFM) | 1484 | 993 | 2270 | 1406 | ||||

Blower Motor BHP | 0.67 | 0.54 | 1.24 | 0.90 | ||||

| ID Blower | Cooling | ID Blower | Cooling | ID Blower | Cooling | ID Blower | Cooling |

Octave Center Freq. | Operation2 | Operation2 | Operation2 | Operation2 | ||||

| Only (dB) | (dB) | Only (dB) | (dB) | Only (dB) | (dB) | Only (dB) | (dB) |

|

|

|

|

| ||||

63 | 77 | 97 | 75 | 95 | 84 | 91 | 82 | 91 |

125 | 72 | 86 | 69 | 85 | 81 | 83 | 78 | 80 |

250 | 60 | 62 | 57 | 59 | 71 | 71 | 66 | 67 |

500 | 53 | 56 | 49 | 54 | 60 | 61 | 55 | 56 |

1000 | 47 | 47 | 42 | 43 | 58 | 59 | 52 | 52 |

2000 | 45 | 46 | 40 | 43 | 54 | 55 | 50 | 50 |

4000 | 46 | 47 | 40 | 42 | 57 | 58 | 52 | 52 |

8000 | 47 | 47 | 45 | 45 | 54 | 54 | 48 | 49 |

1.Tested in accordance with ARI Standard 260. Refer to 2001 Standard for Sound Rating of Ducted Air Moving and Conditioning Equipment .

2.Cooling Operation – ID blower, compressor and outdoor fan operating.

3.Test Duct Dimension: 12 in. wide x 18 in. high x 8 ft. long (0.30m x 0.46m x 2.44m).

4.Test duct termination is flush with reverberation room wall.

5.Duct end (sound reflection) correction: (11, 6, 3, 1, 0, 0, 0, 0) dB at (63, 125, 250, 500, 1k, 4k, 8k) Hz.

Johnson Controls Unitary Products | 11 |