MAINTENANCE AND REPAIR INSTRUCTIONS

LINE INSTALLATION FOR THE SPEEDSPOOL®

Always use genuine Ryobi 0.080 inch (2.03 mm) replacement line. Line other than specified may make the engine overheat or fail.

WARNING: Never use

There are two methods to replace the SpeedSpool® trimming line.

•Wind the inner reel with new line

•Install a prewound inner reel

Winding the Inner Reel With New Line

NOTE: It Is unnecessary to remove the bump knob to install new trimming line.

1.Cut two pieces of 0.080 inch (2.03 mm) trimming line, 10 feet (3 m) long.

WARNING: Always use the correct line length when installing trimming line on the unit. The line may not release properly if the line is too long.

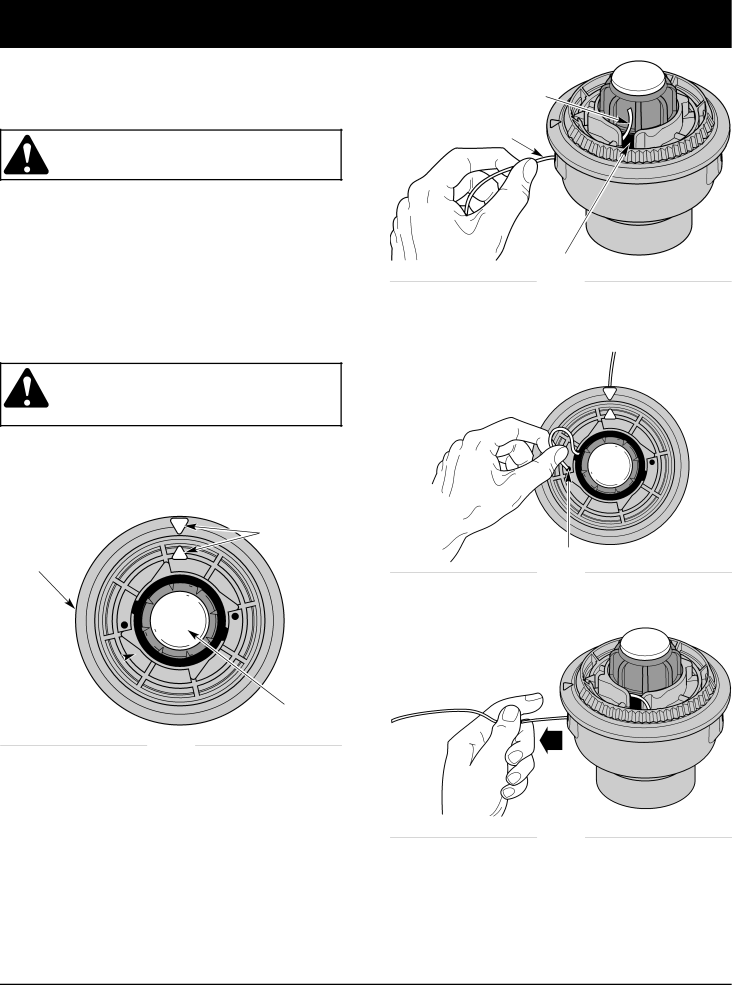

2.Hold the outer spool and turn the inner reel counterclockwise to line up the arrows on the outer spool and inner reel (Fig. 17).

Top View Of The SpeedSpool®

Arrows

Outer Spool

Inner Reel ![]()

Bump Knob

Fig. 17

3.Pull old line out of the line loading and line locking holes (Figs. 18 and 19).

4.Insert a piece of trimming line into one of the two eyelets in the outer spool. Push it up through the line loading hole in the inner reel (Fig. 18). Do not bend the line when inserting it into the eyelet.

Trimming Line

Eyelet

Line Loading Hole

Fig. 18

5.Insert the line into the locking hole (Fig. 18). Do not push the line more than 1/2 inch (12.7 mm) into the line locking hole. When inserted correctly the line will form a small loop (Fig. 19).

Line Locking Hole

Fig. 19

6.Pull the line from the outer spool until the line is tight against the inner reel (Fig. 20).

Fig. 20

16