| TROUBLESHOOTING | |||

|

|

|

|

|

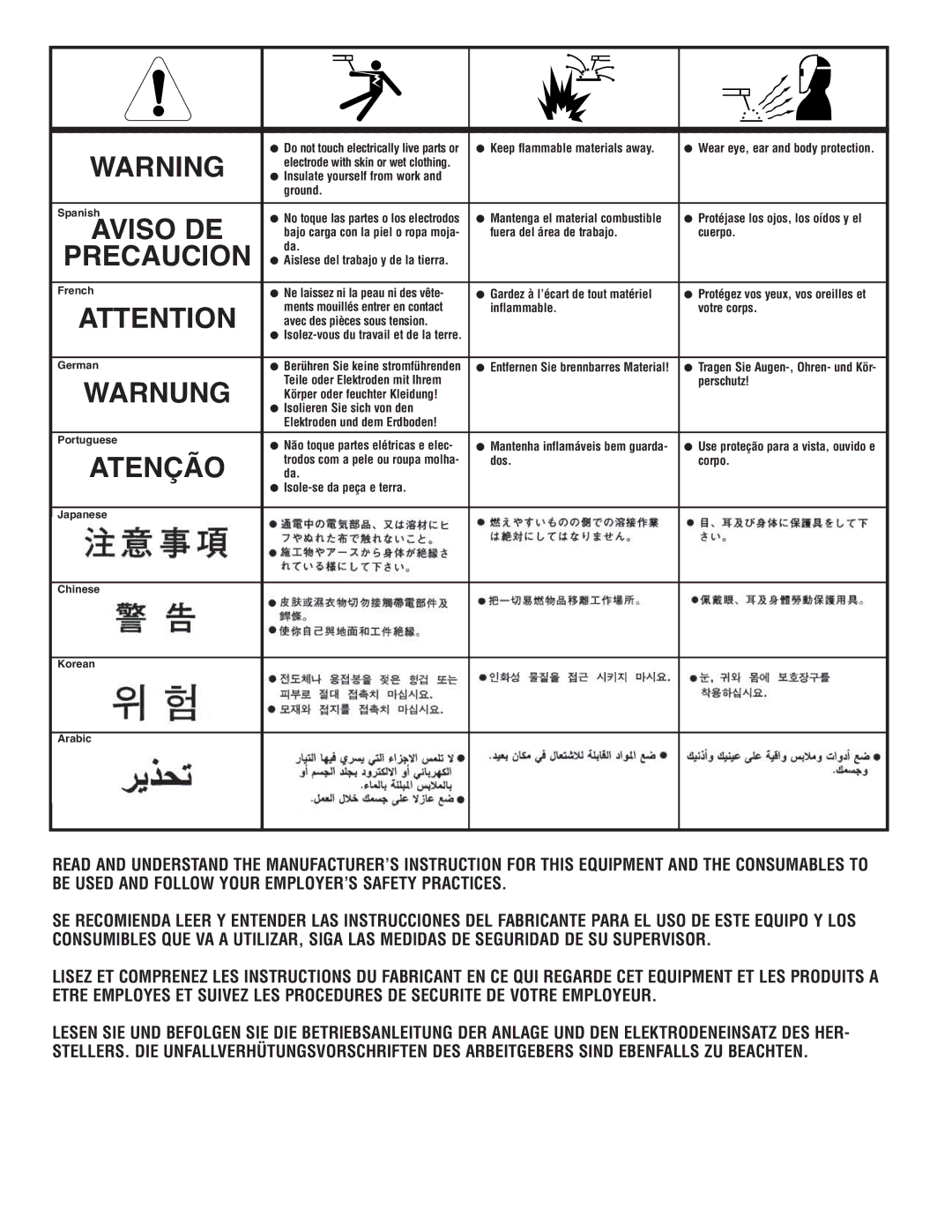

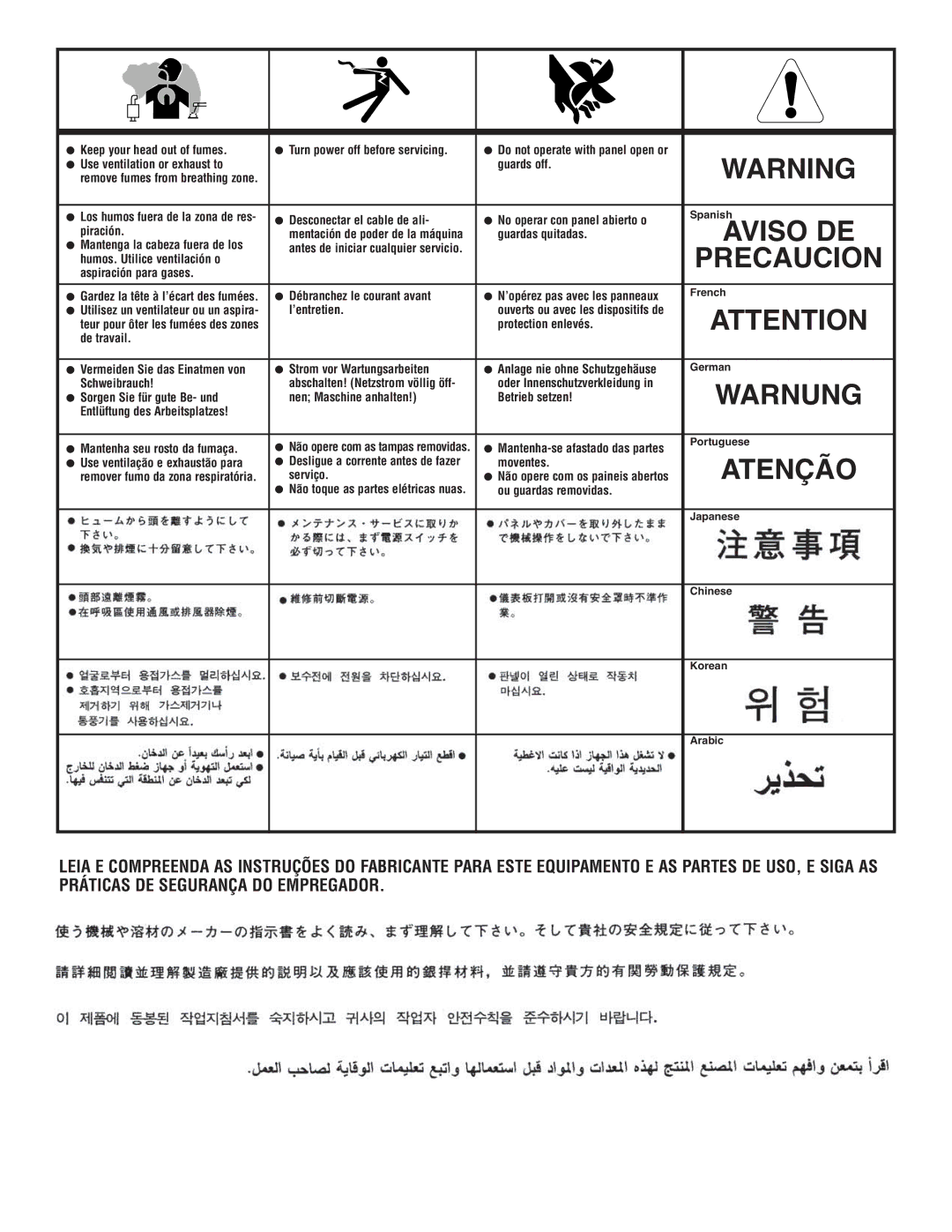

| Observe all Safety Guidelines detailed throughout this manual | |||

|

|

|

|

|

| PROBLEMS | POSSIBLE | RECOMMENDED |

|

| (SYMPTOMS) | CAUSE | COURSE OF ACTION |

|

|

|

|

|

|

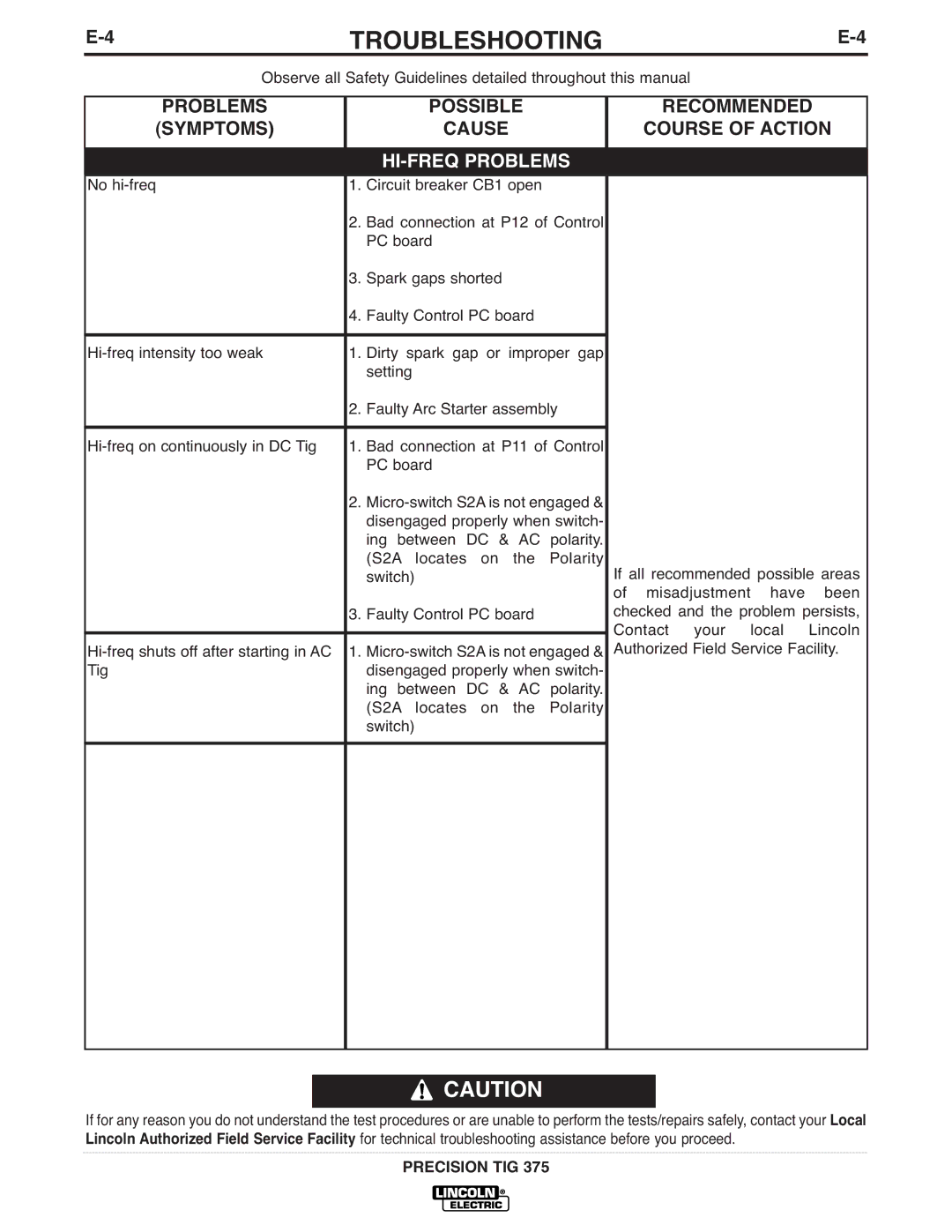

HI-FREQ PROBLEMS

No | 1. Circuit breaker CB1 open | |

| 2. | Bad connection at P12 of Control |

|

| PC board |

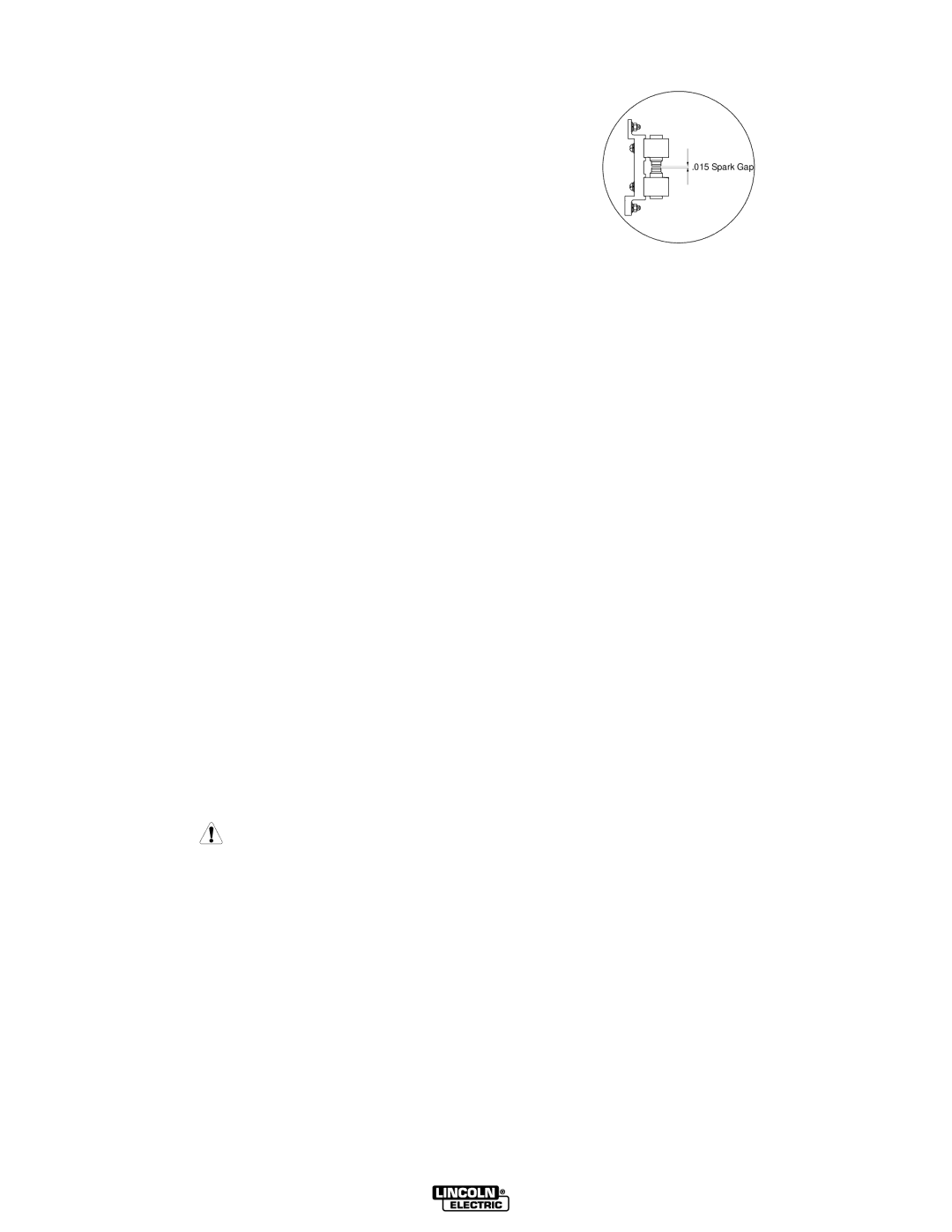

| 3. | Spark gaps shorted |

| 4. | Faulty Control PC board |

|

| |

1. Dirty spark gap or improper gap | ||

|

| setting |

| 2. | Faulty Arc Starter assembly |

|

| |

1. Bad connection at P11 of Control | ||

|

| PC board |

| 2. | |

|

| disengaged properly when switch- |

|

| ing between DC & AC polarity. |

|

| (S2A locates on the Polarity |

|

| switch) |

| 3. | Faulty Control PC board |

|

| |

1. | ||

Tig |

| disengaged properly when switch- |

|

| ing between DC & AC polarity. |

|

| (S2A locates on the Polarity |

|

| switch) |

|

|

|

|

|

|

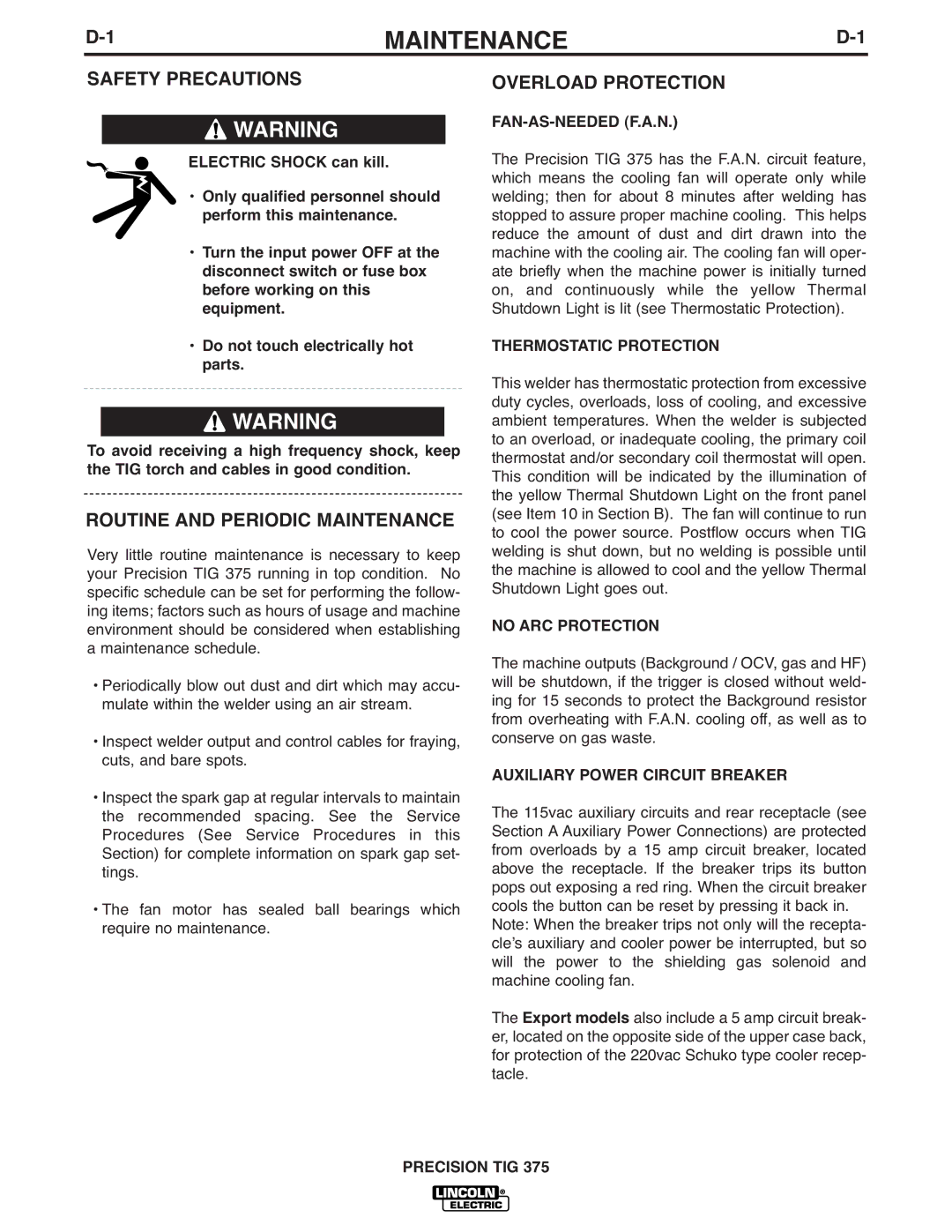

If all recommended possible areas of misadjustment have been checked and the problem persists, Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.