|

|

| INSTALLATION | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

TECHNICAL | ||||||||||||

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

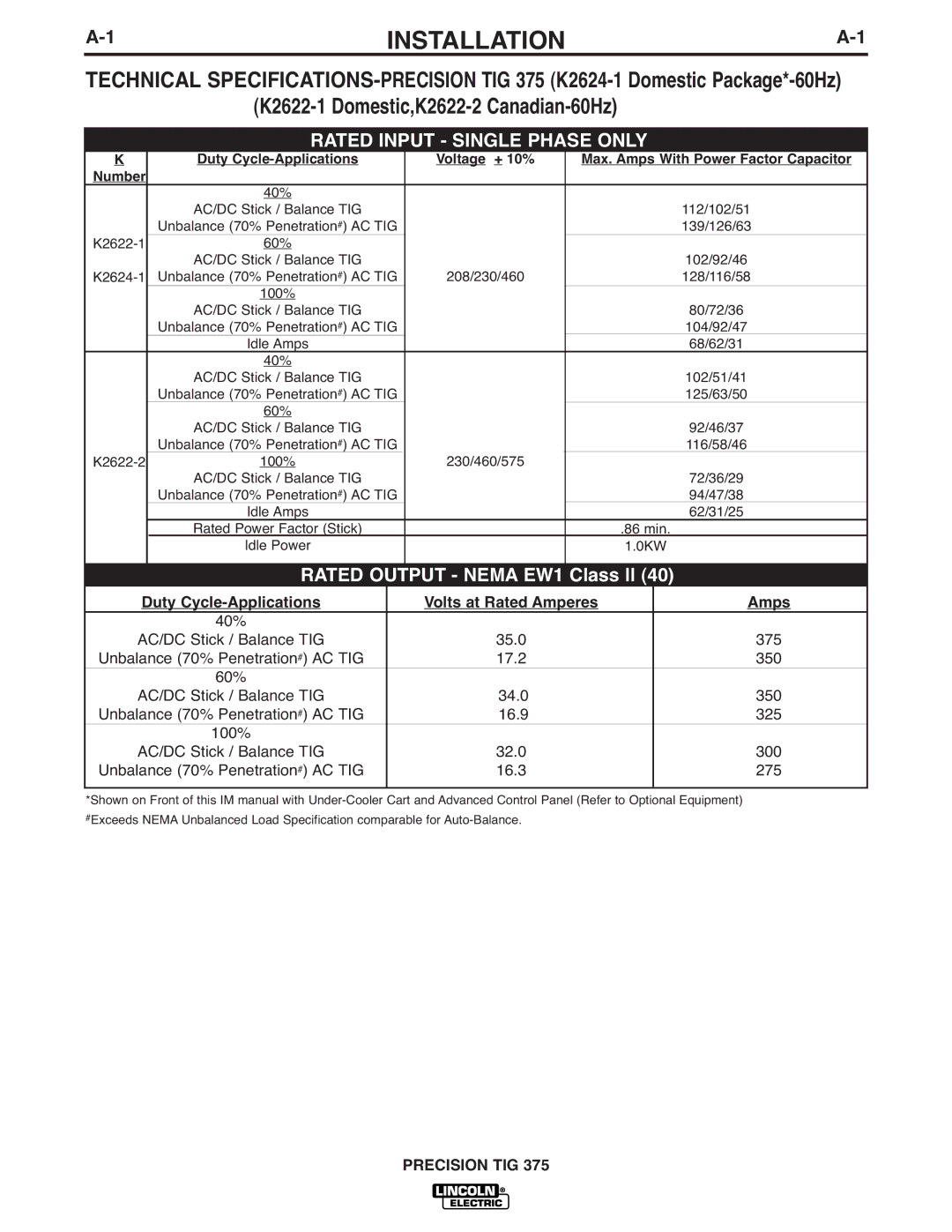

| RATED INPUT - SINGLE PHASE ONLY | |||||||

| K |

|

| Duty |

|

| Voltage + 10% |

|

| Max. Amps With Power Factor Capacitor |

| |

| Number |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| 40% |

|

|

|

|

|

|

|

|

|

|

|

| AC/DC Stick / Balance TIG |

|

|

|

|

| 112/102/51 |

|

|

|

|

|

| Unbalance (70% Penetration#) AC TIG |

|

|

|

|

| 139/126/63 |

|

|

|

| 60% |

|

|

|

|

|

|

| ||

|

|

|

|

| AC/DC Stick / Balance TIG |

|

|

|

|

| 102/92/46 |

|

|

|

| Unbalance (70% Penetration#) AC TIG |

|

| 208/230/460 |

|

| 128/116/58 |

| ||

|

|

|

|

| 100% |

|

|

|

|

| 80/72/36 |

|

|

|

|

|

| AC/DC Stick / Balance TIG |

|

|

|

|

|

| |

|

|

|

|

| Unbalance (70% Penetration#) AC TIG |

|

|

|

|

| 104/92/47 |

|

|

|

|

|

|

|

|

|

|

|

| 68/62/31 |

|

|

|

|

|

| Idle Amps |

|

|

|

|

|

| |

|

|

|

|

| 40% |

|

|

|

|

|

|

|

|

|

|

|

| AC/DC Stick / Balance TIG |

|

|

|

|

| 102/51/41 |

|

|

|

|

|

| Unbalance (70% Penetration#) AC TIG |

|

|

|

|

| 125/63/50 |

|

|

|

|

|

| 60% |

|

|

|

|

|

|

|

|

|

|

|

| AC/DC Stick / Balance TIG |

|

|

|

|

| 92/46/37 |

|

|

|

|

|

| Unbalance (70% Penetration#) AC TIG |

|

|

|

|

| 116/58/46 |

|

|

|

| 100% |

|

| 230/460/575 |

|

|

|

| ||

|

|

|

|

| AC/DC Stick / Balance TIG |

|

|

|

|

| 72/36/29 |

|

|

|

|

|

| Unbalance (70% Penetration#) AC TIG |

|

|

|

|

| 94/47/38 |

|

|

|

|

|

| Idle Amps |

|

|

|

|

| 62/31/25 |

|

|

|

|

|

| Rated Power Factor (Stick) |

|

|

|

|

| .86 min. |

|

|

|

|

|

| Idle Power |

|

|

|

|

| 1.0KW |

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RATED OUTPUT - NEMA EW1 Class ll (40)

|

|

|

|

|

|

|

|

|

| Duty |

|

| Volts at Rated Amperes |

|

| Amps |

|

| 40% |

|

|

|

|

|

|

|

| AC/DC Stick / Balance TIG |

|

| 35.0 |

|

| 375 |

|

| Unbalance (70% Penetration#) AC TIG |

|

| 17.2 |

|

| 350 |

|

| 60% |

|

|

|

|

|

|

|

| AC/DC Stick / Balance TIG |

|

| 34.0 |

|

| 350 |

|

| Unbalance (70% Penetration#) AC TIG |

|

| 16.9 |

|

| 325 |

|

| 100% |

|

|

|

|

|

|

|

| AC/DC Stick / Balance TIG |

|

| 32.0 |

|

| 300 |

|

| Unbalance (70% Penetration#) AC TIG |

|

| 16.3 |

|

| 275 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

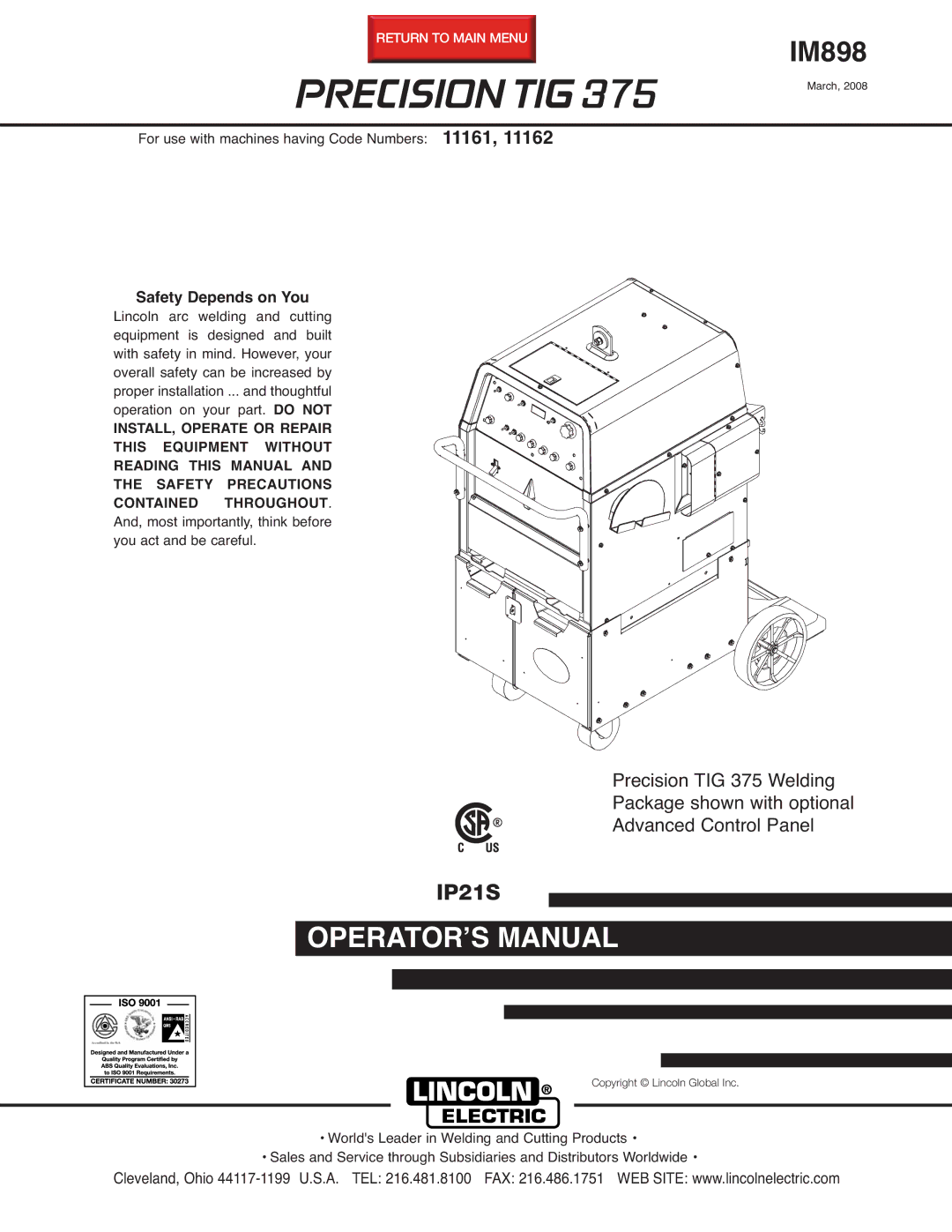

*Shown on Front of this IM manual with

#Exceeds NEMA Unbalanced Load Specification comparable for