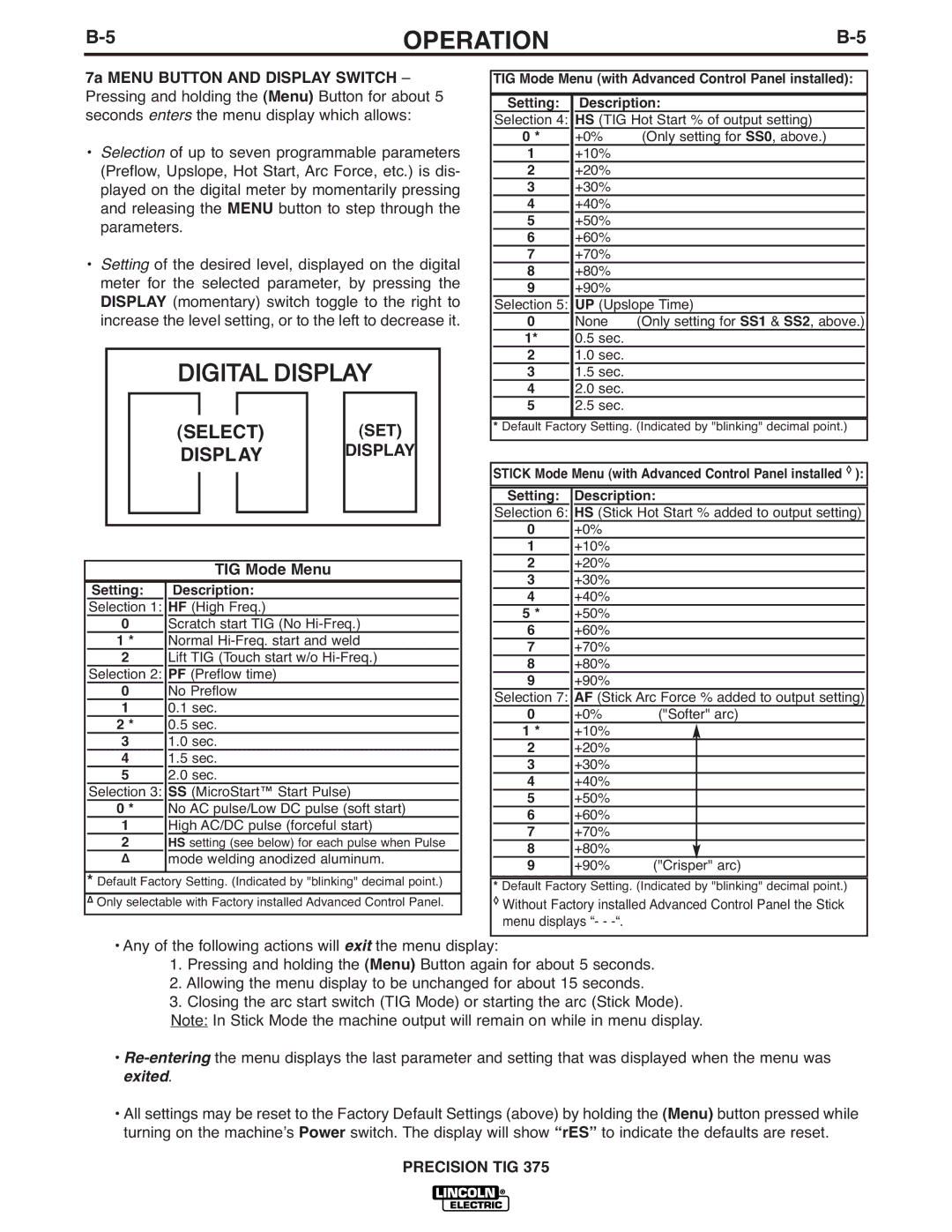

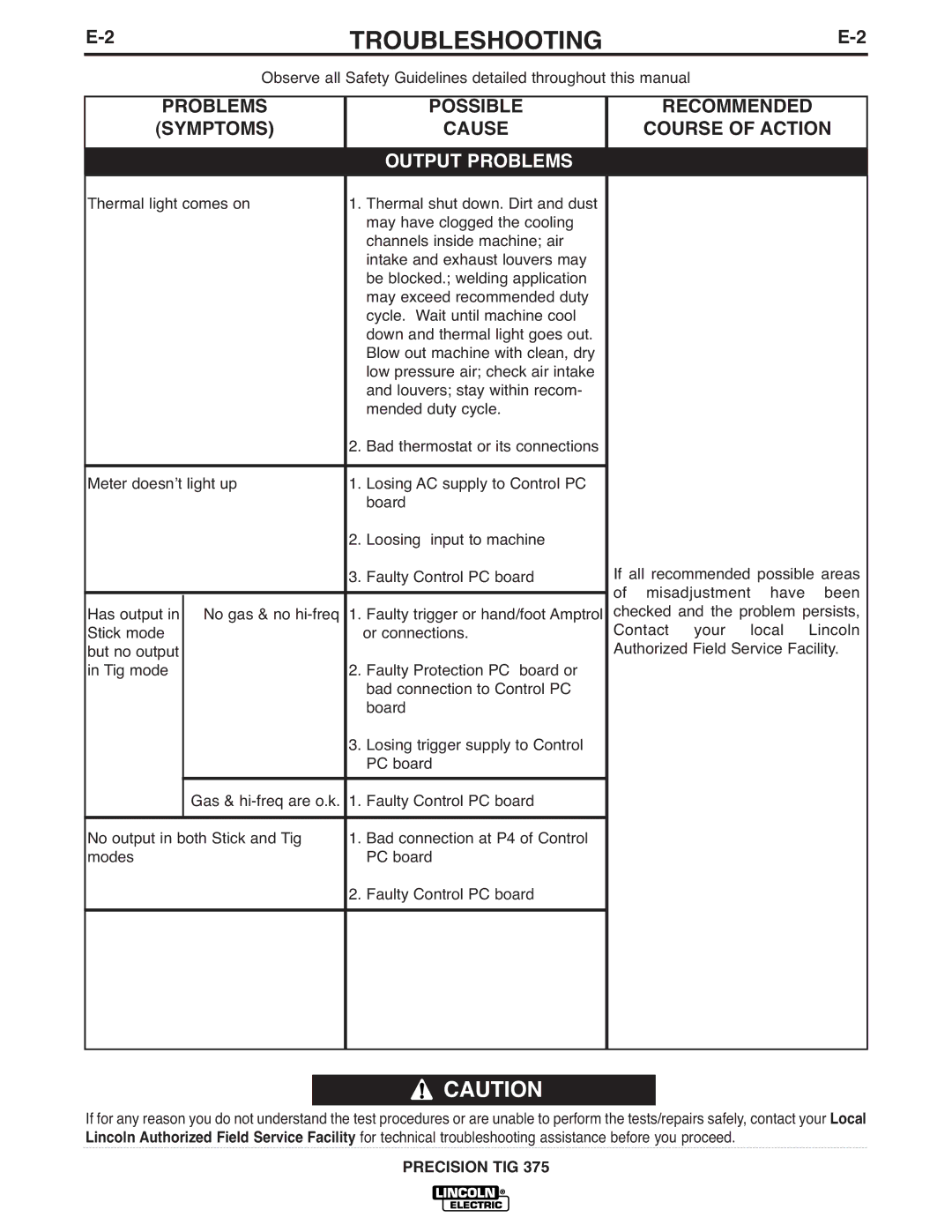

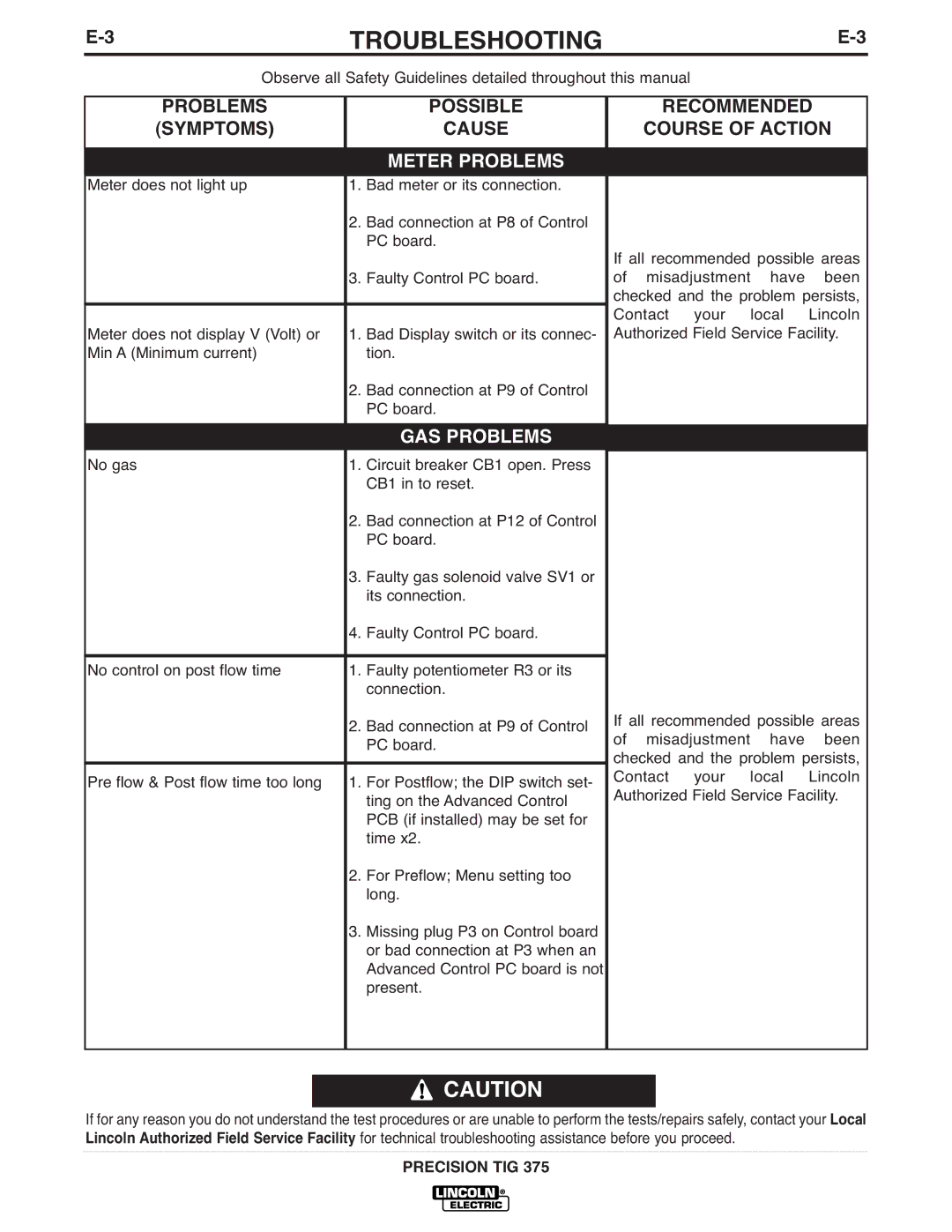

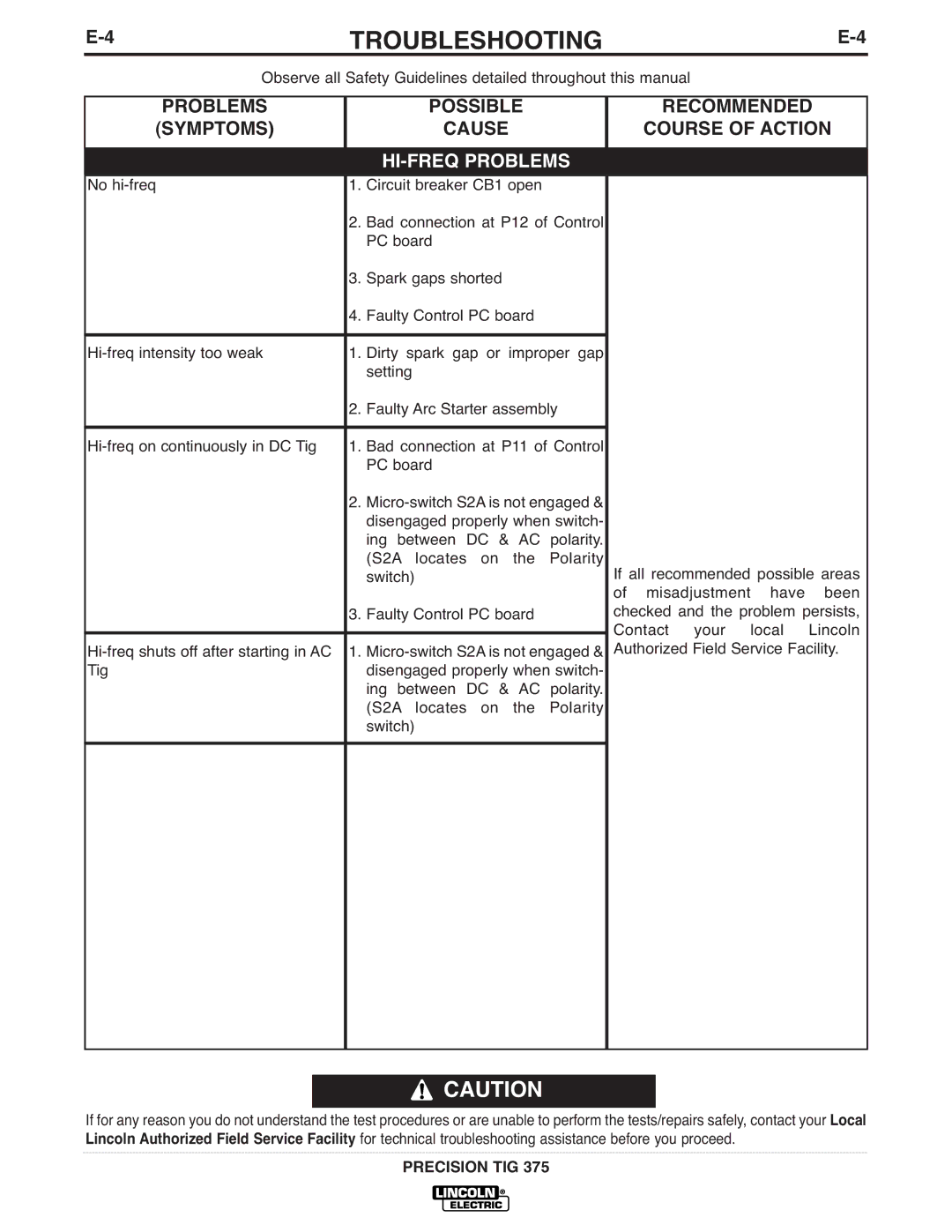

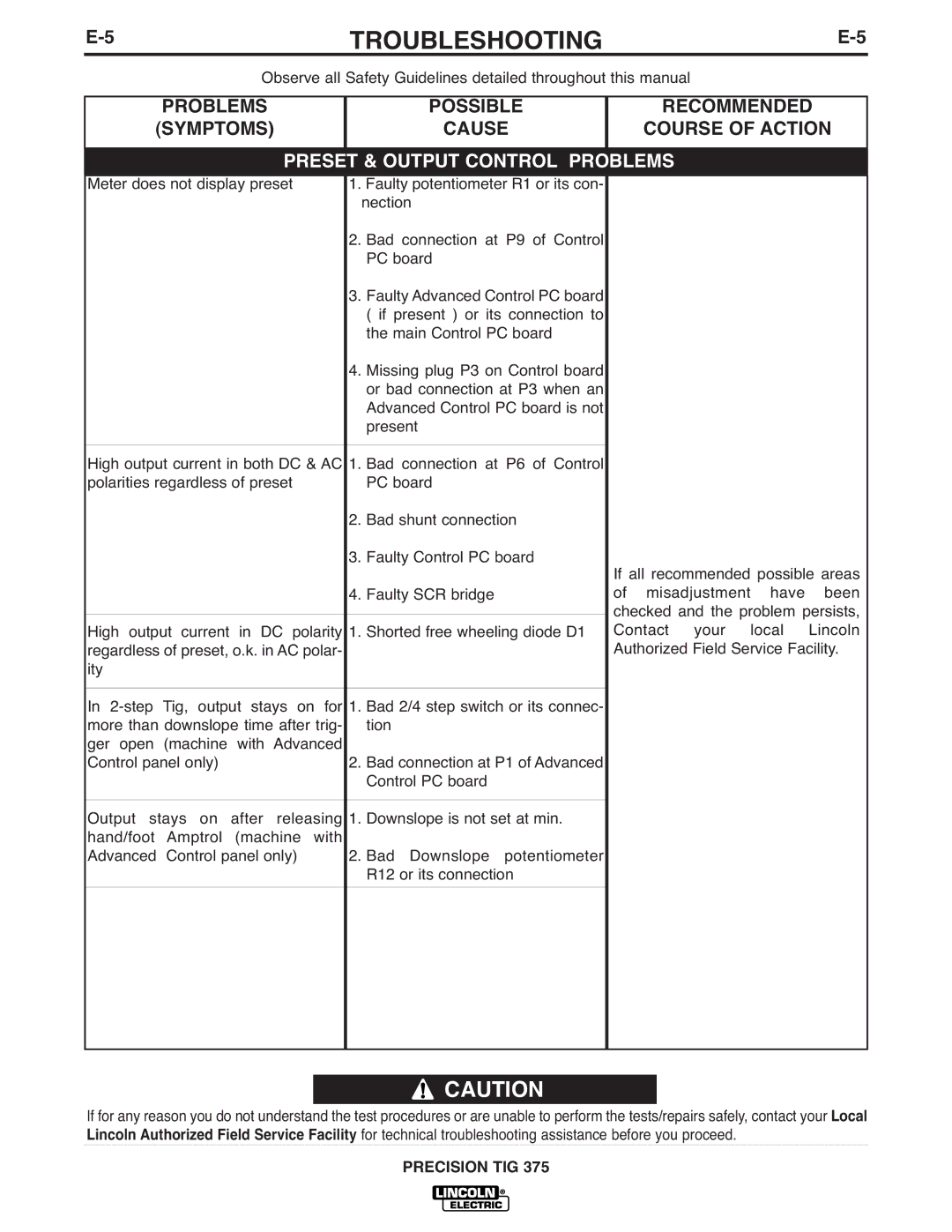

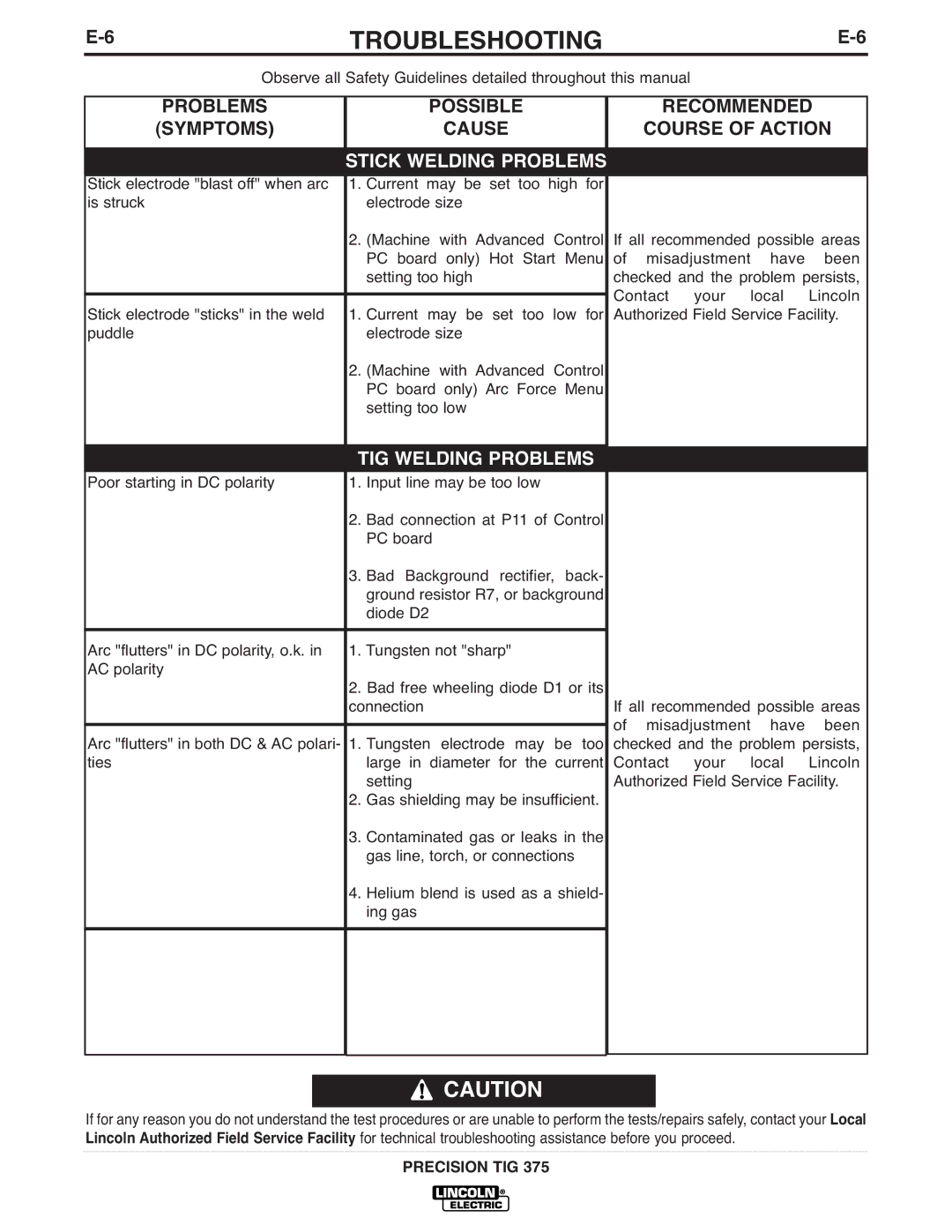

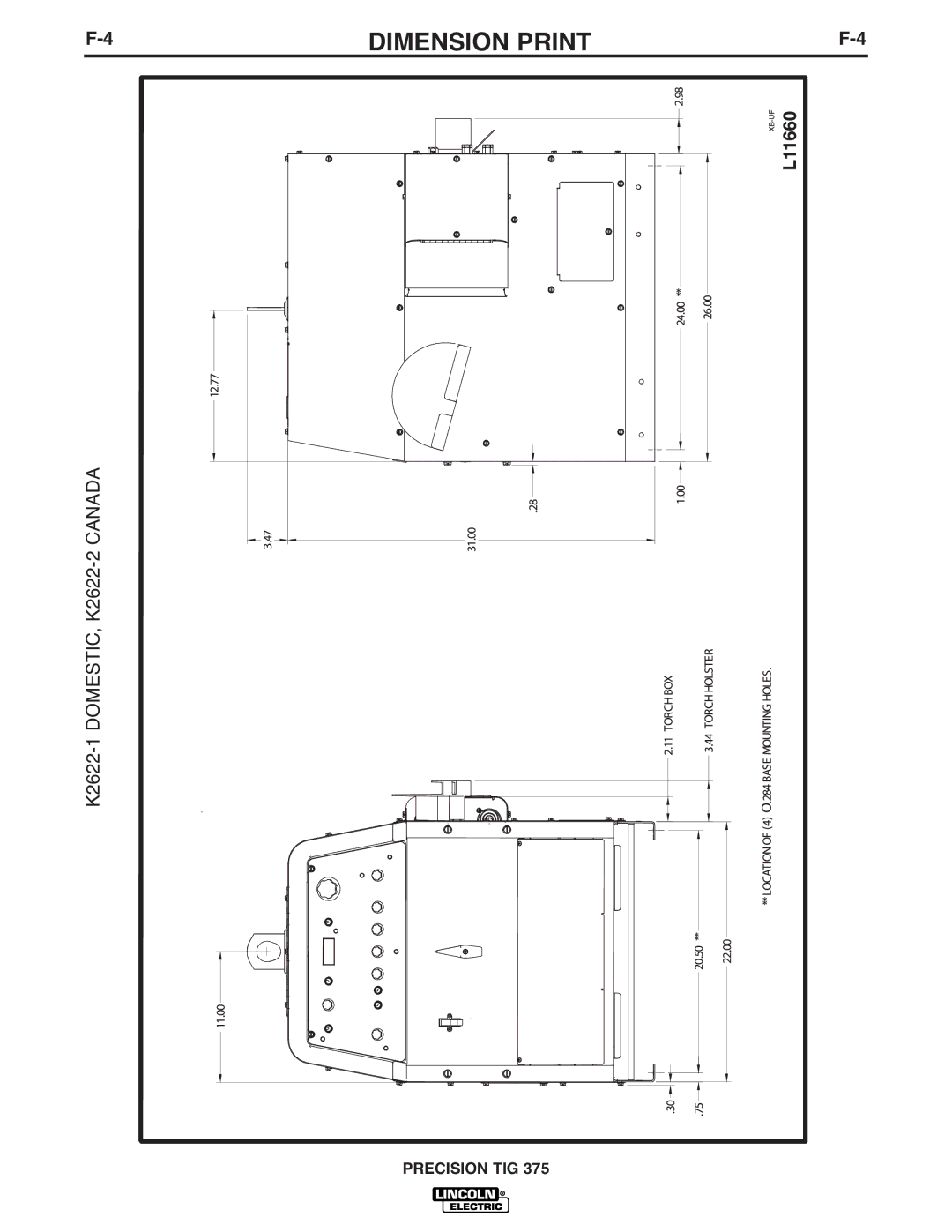

OPERATION | ||

|

|

|

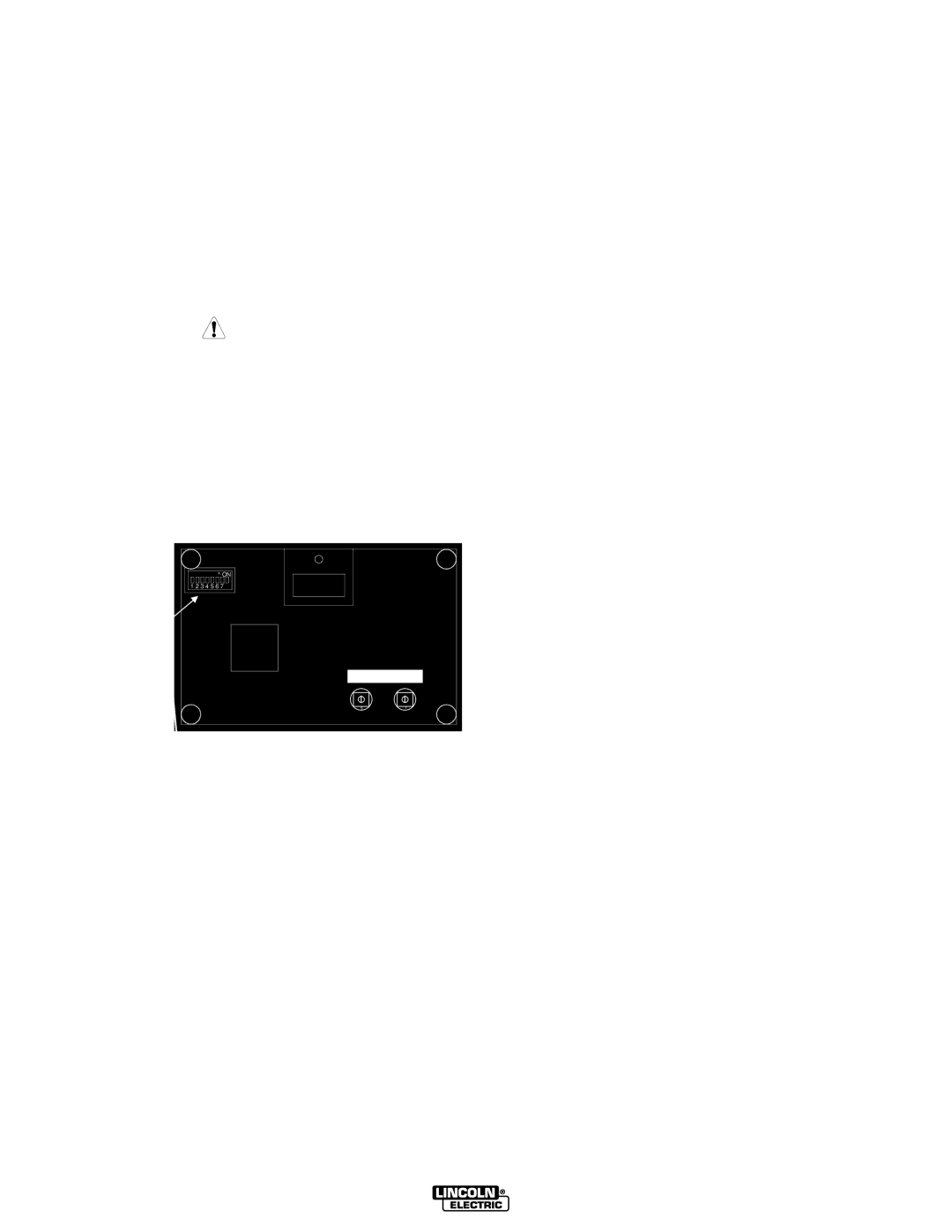

INTERNAL SET UP CONTROLS

Precision TIG 375 Advanced Panel has the following additional control features which are set up using the DIP Switch (S1) provided on the internal panel of this option.

Access to this internal panel is obtained by removing the two screws securing the top corners of the Precision TIG front control panel and swinging the con- trol panel down to reveal the panel mounted on the sur- face of the Precision TIG Control board:

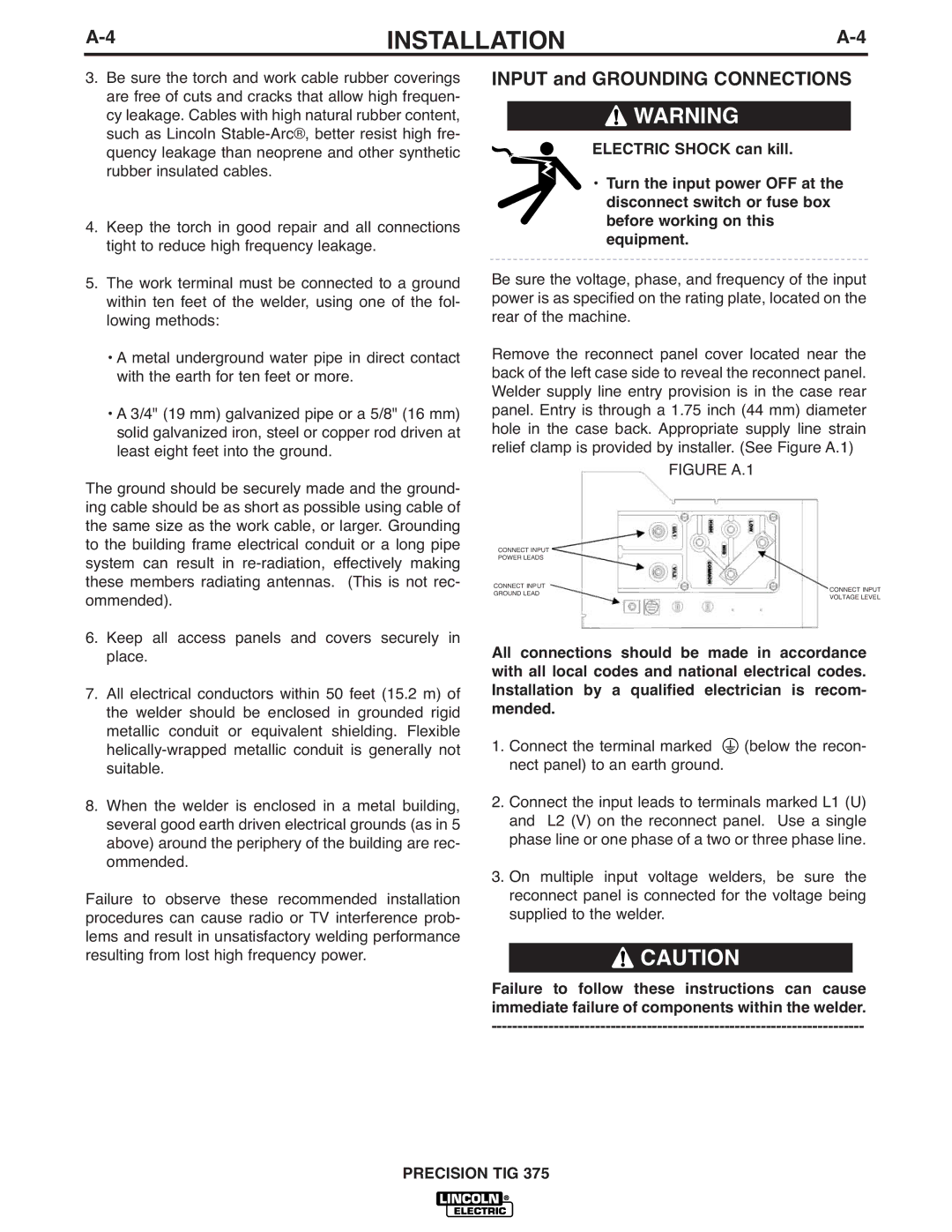

![]() CAUTION

CAUTION

•THE CONTROL BOARDS CONTAIN STATIC SEN- SITIVE COMPONENTS

•To avoid possible damage to these components be sure to ground yourself by touching the

machineʼs sheet metal while handling or making settings on the internal control box components.

PRECISION TIG ADVANCED PANEL

(M21115 Internal Panel)

TIG WELDING FEATURES

The following DIP switch feature selections function only when the Precision TIG is set to TIG mode (See Item 3):

• Switch #1 Postflow Time Extension* (See Item 9)

ON – Doubles the time ranges.

OFF – Standard time range (as shipped).

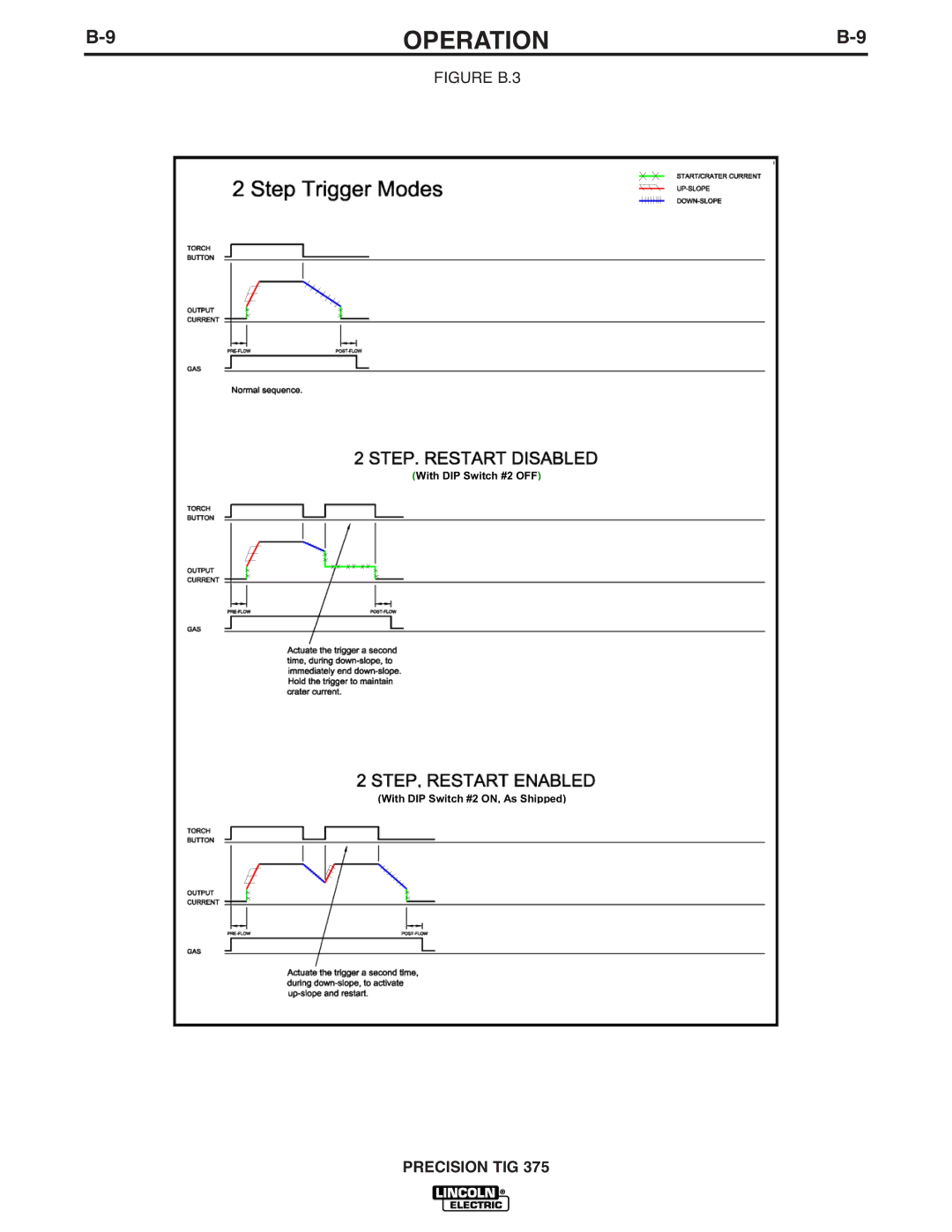

•Switch #2

ON – Restart Enabled (as shipped).

OFF – Restart Disabled.

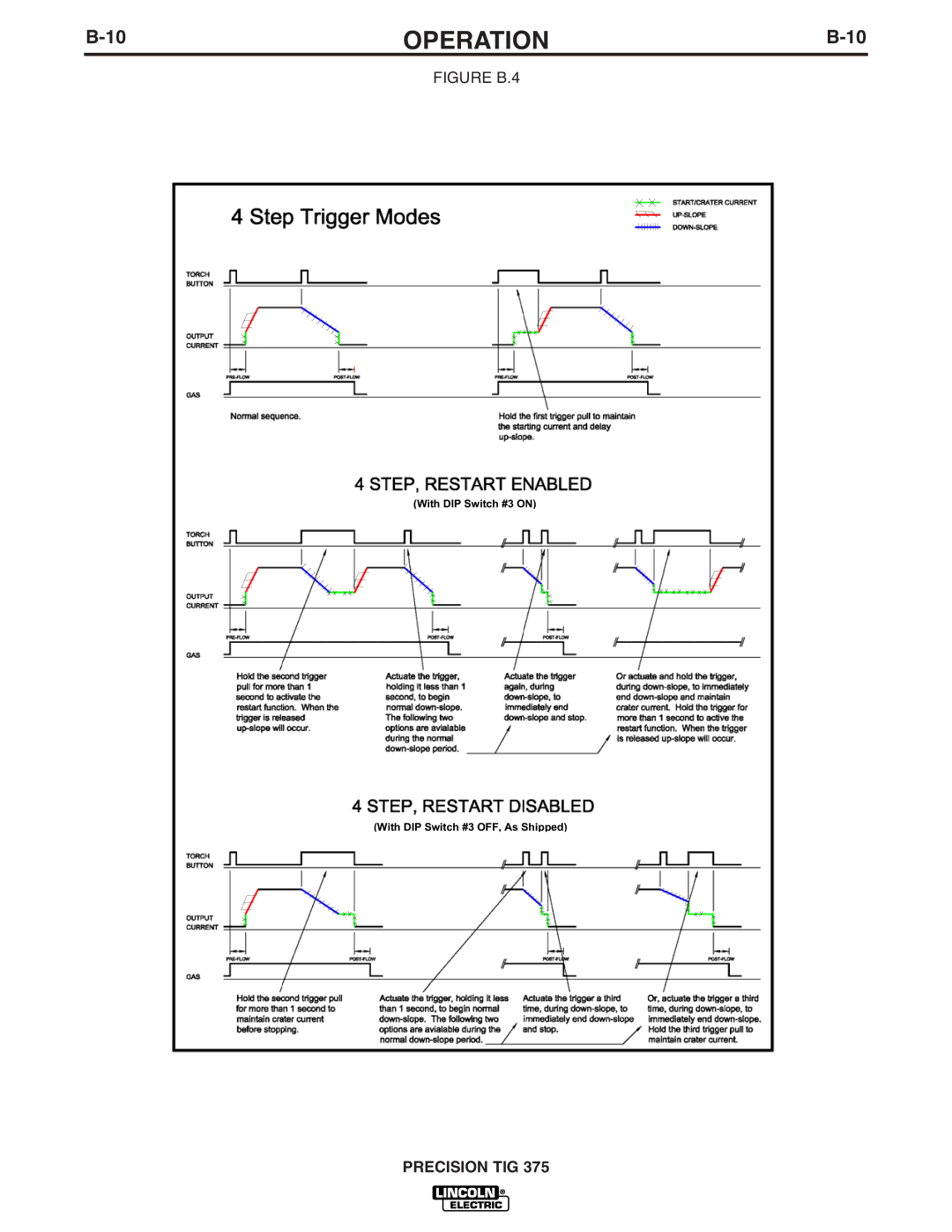

•Switch #3

ON – Restart Enabled.

OFF – Restart Disabled (as shipped)

• Switch #4 Lift TIG Starting - Does not function |

(See Item 7a) |

• Switch #5 |

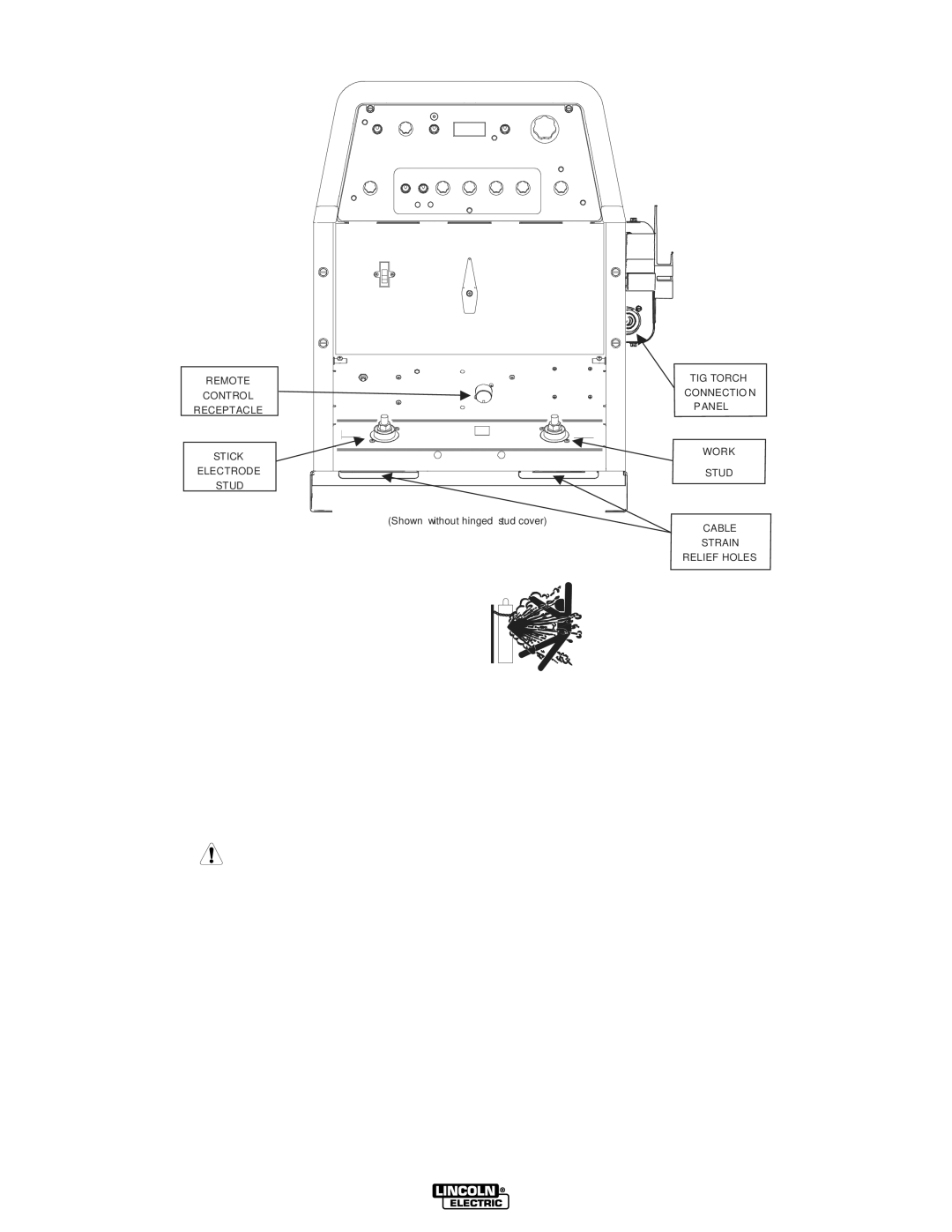

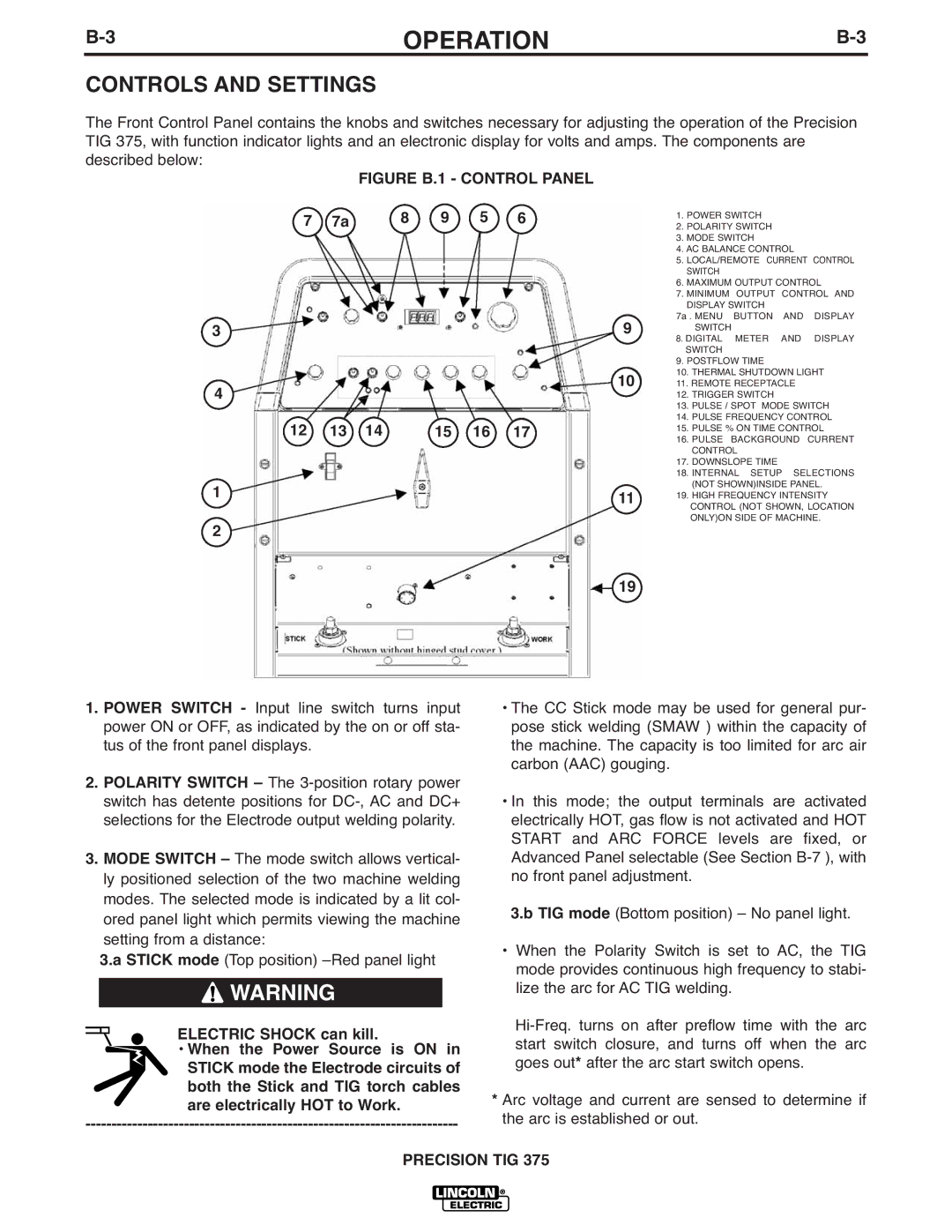

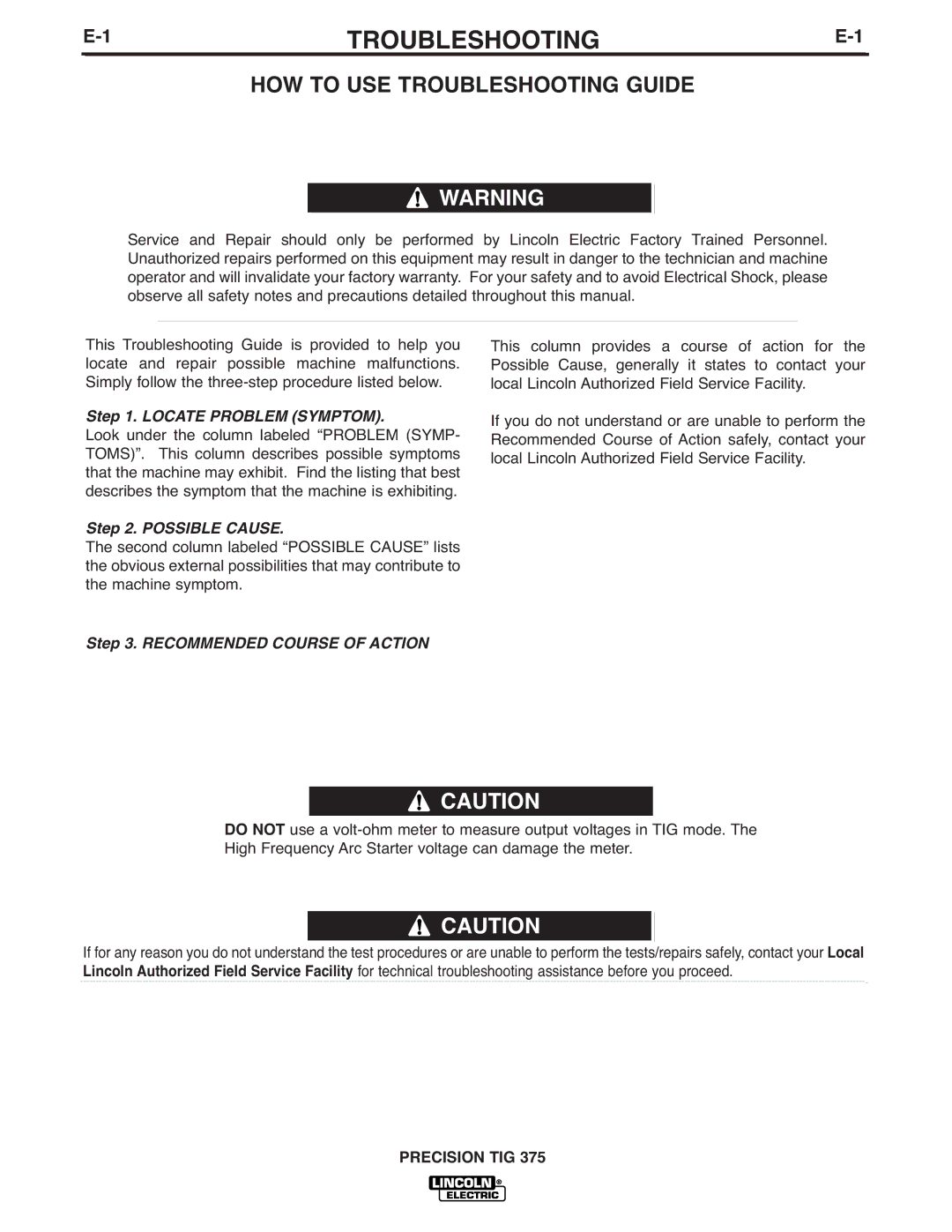

DIP SWITCH (S1)

^ ON |

1 2 3 4 5 6 7 |

ON - Level is minimum rating of the machine (2A) OFF – Level (as shipped) is Minimum Output setting

(same as Start level).

![]() (DOES NOT FUNCTION)

(DOES NOT FUNCTION)![]()

HOT START | F | |

ARC FORCE | ||

|

ON

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

OFF

DIP SWITCH POSITIONS (FACTORY SETTINGS)

STICK WELDING FEATURES

• Switch #6 Hot Start Level – Does not function (See Item 7a)

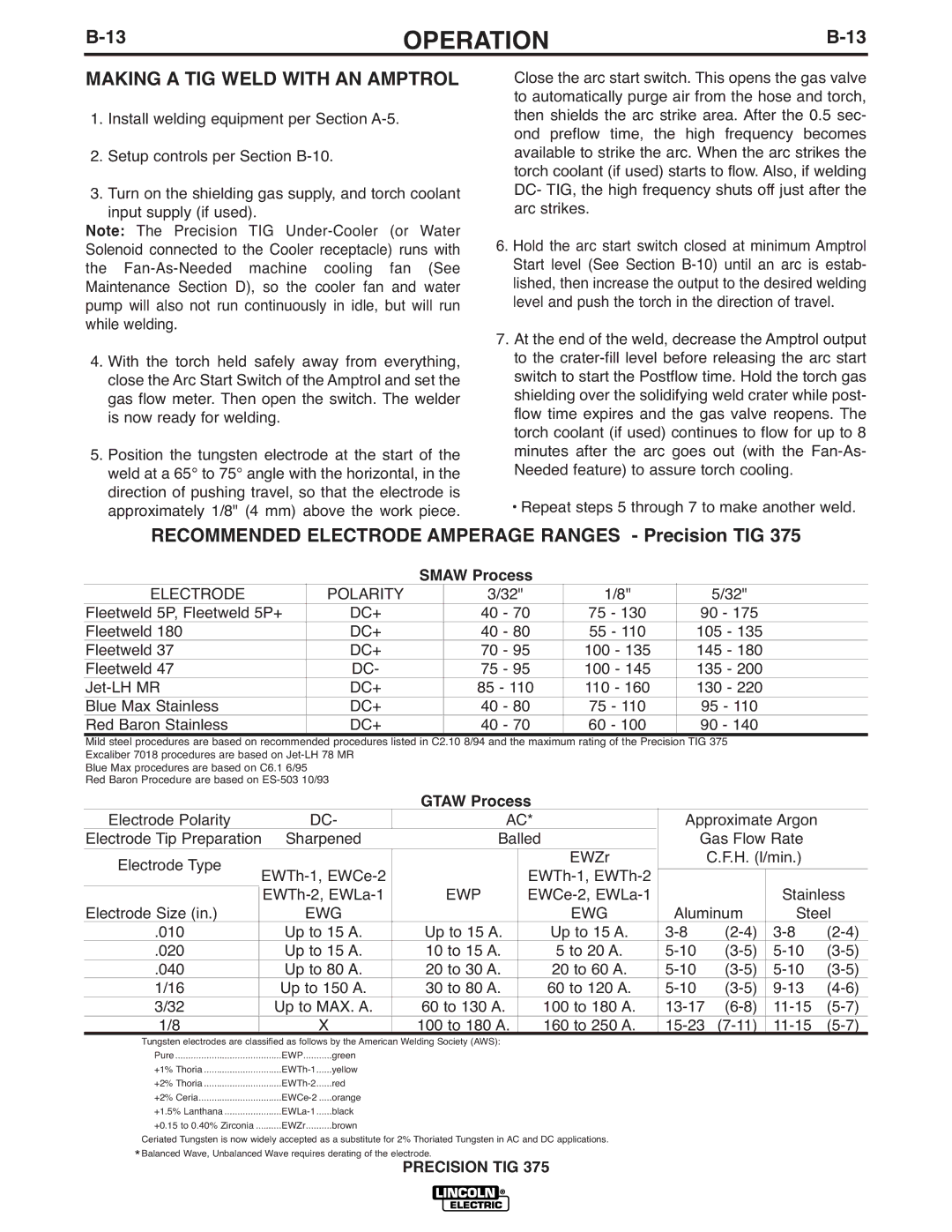

•Switch #7 Arc Force Level – Does not function (See Item 7a)