Return to Section TOC

Return to Master TOC

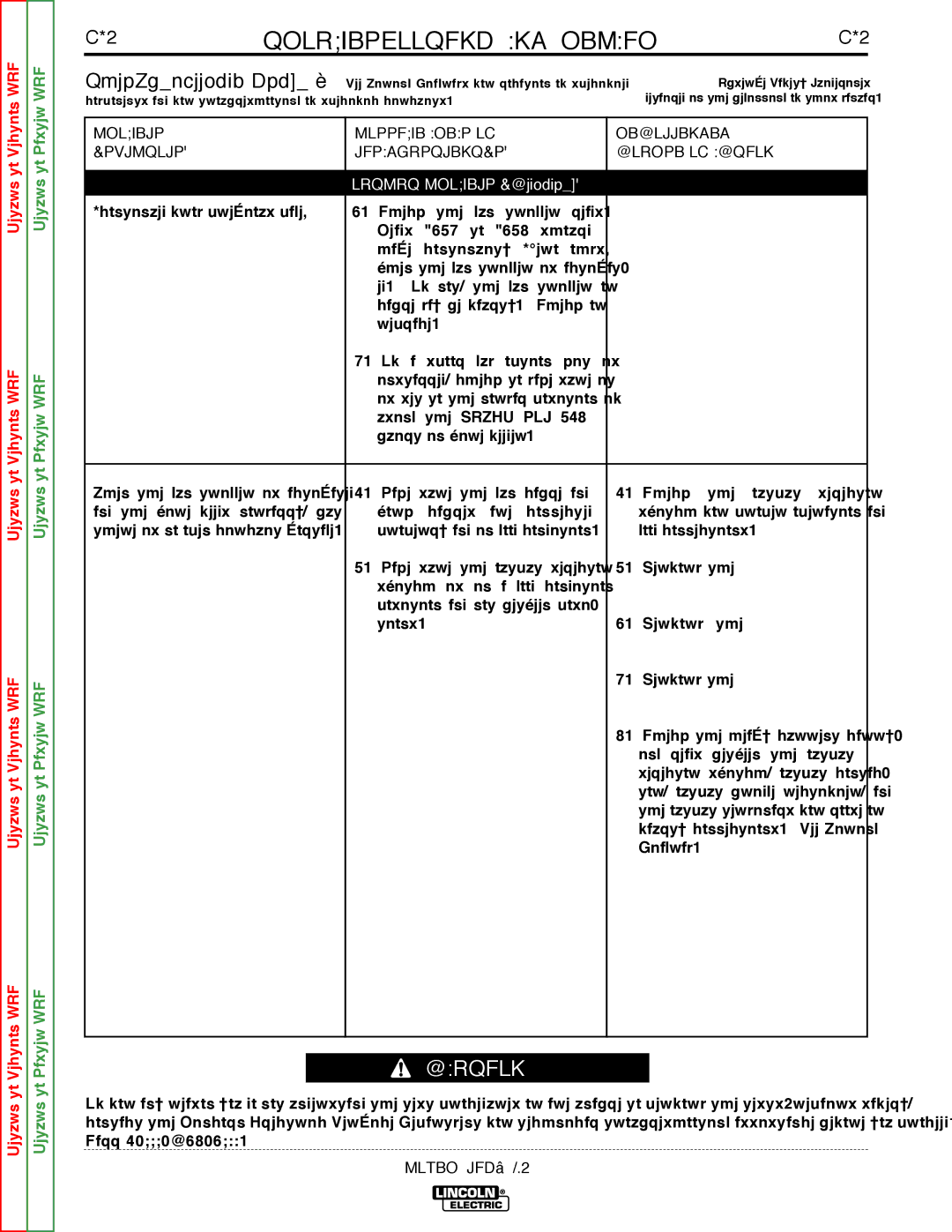

THEORY OF OPERATION |

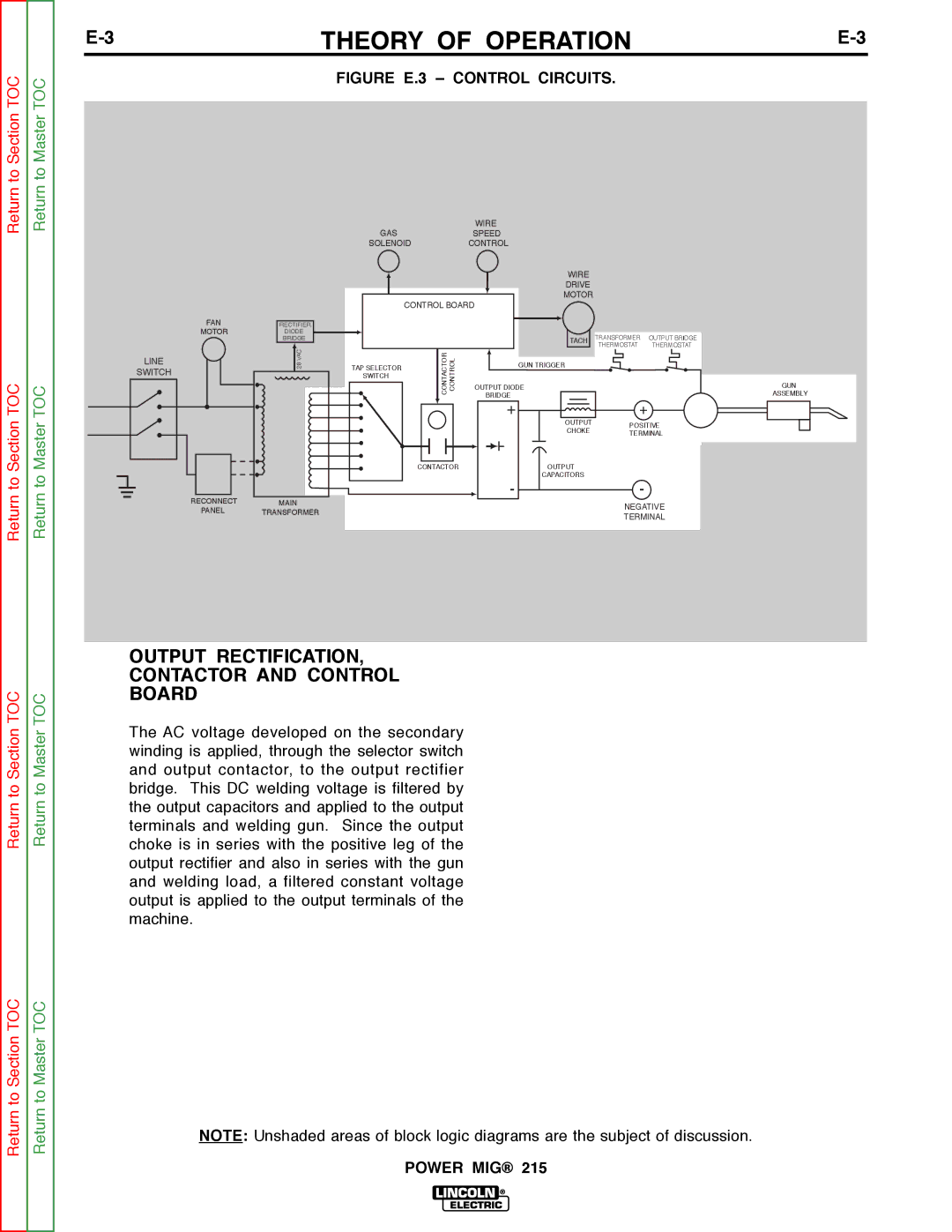

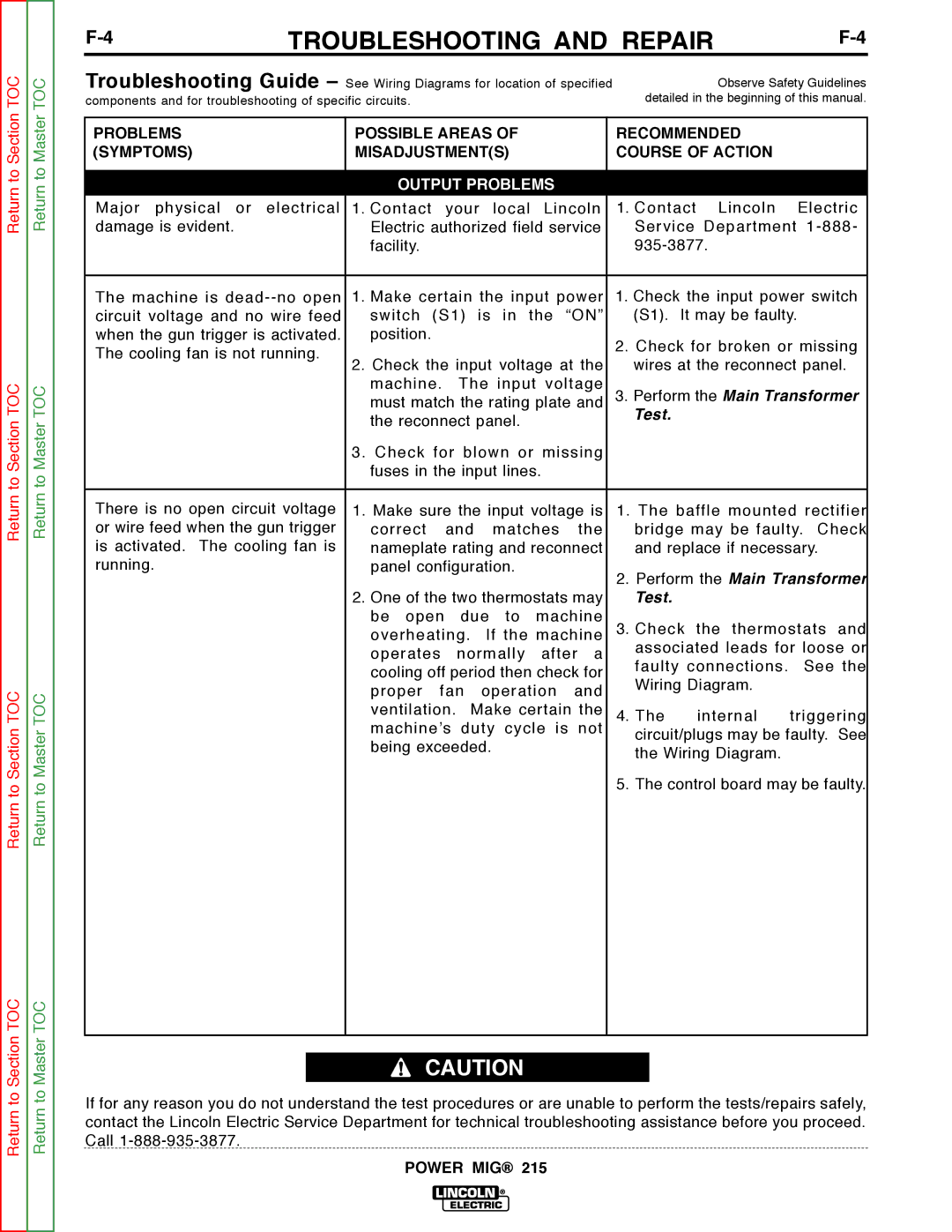

FIGURE E.3 – CONTROL CIRCUITS.

WIRE

GASSPEED

SOLENOIDCONTROL

FAN

MOTOR

LINE

SWITCH

RECTIFIER

DIODE

BRIDGE

VAC28TAP SELECTOR SWITCH

CONTROL BOARD

CONTACTOR | CONTROL |

CONTACTOR

WIRE

DRIVE

MOTOR

TACH

GUN TRIGGER

OUTPUT DIODE

BRIDGE

+

OUTPUT

CHOKE

OUTPUT

CAPACITORS

-

TRANSFORMER | OUTPUT BRIDGE | ||||||

THERMOSTAT | THERMOSTAT | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+

POSITIVE

TERMINAL

-

GUN

ASSEMBLY

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

OUTPUT RECTIFICATION,

CONTACTOR AND CONTROL

BOARD

The AC voltage developed on the secondary winding is applied, through the selector switch and output contactor, to the output rectifier bridge. This DC welding voltage is filtered by the output capacitors and applied to the output terminals and welding gun. Since the output choke is in series with the positive leg of the output rectifier and also in series with the gun and welding load, a filtered constant voltage output is applied to the output terminals of the machine.

NOTE: Unshaded areas of block logic diagrams are the subject of discussion.