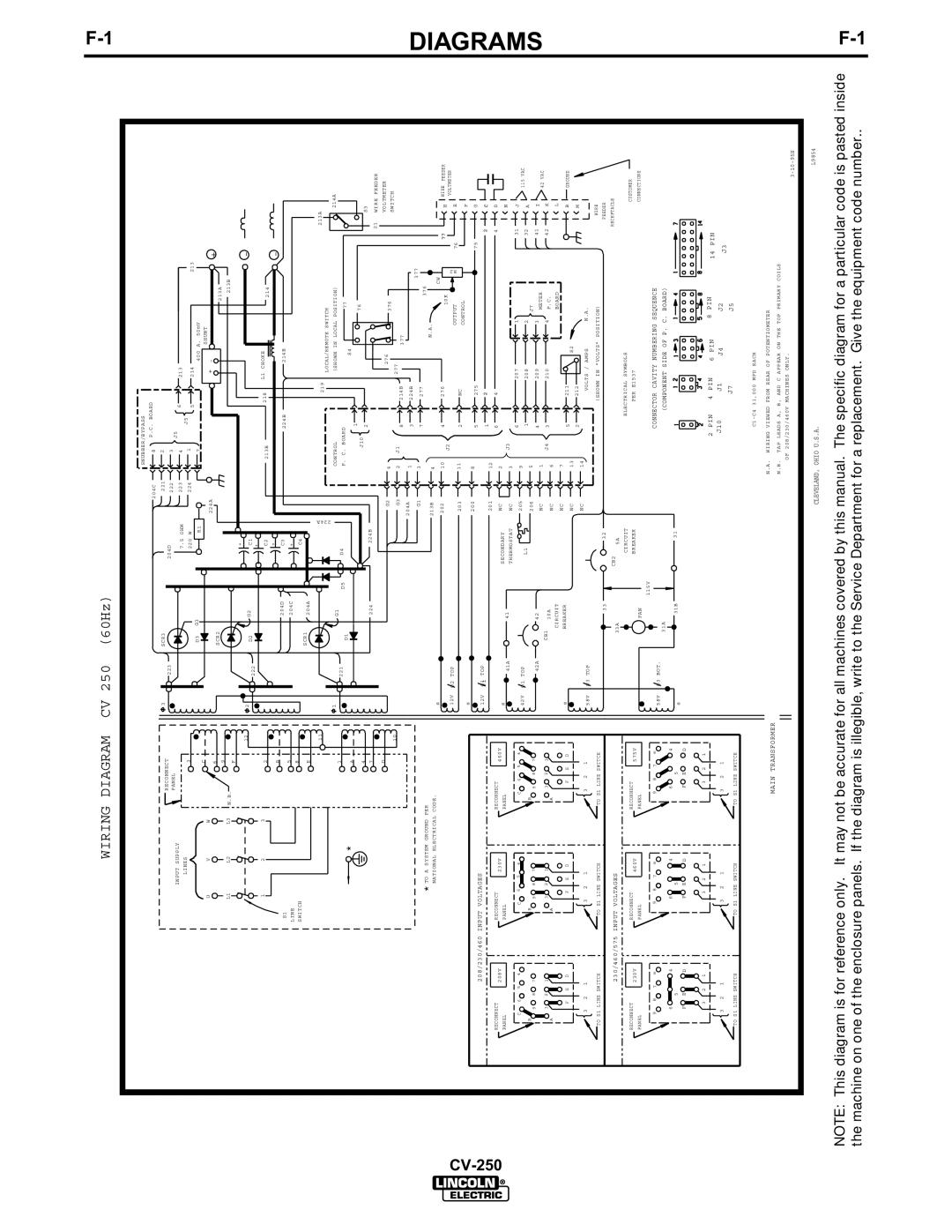

DIAGRAMS | ||

|

|

|

|

|

|

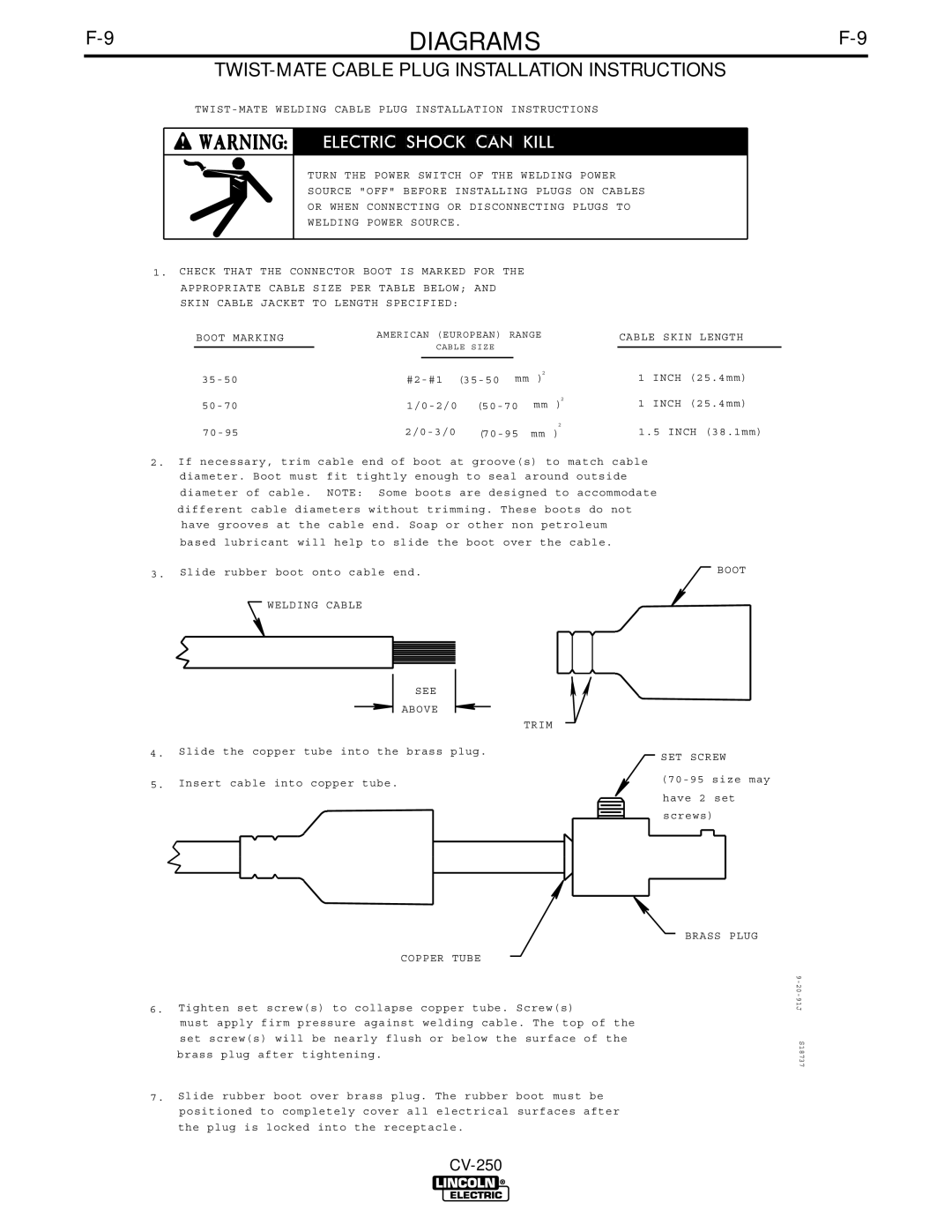

TURN THE POWER SWITCH OF THE WELDING POWER

SOURCE "OFF" BEFORE INSTALLING PLUGS ON CABLES

OR WHEN CONNECTING OR DISCONNECTING PLUGS TO

WELDING POWER SOURCE.

1.CHECK THAT THE CONNECTOR BOOT IS MARKED FOR THE APPROPRIATE CABLE SIZE PER TABLE BELOW; AND SKIN CABLE JACKET TO LENGTH SPECIFIED:

BOOT MARKING | AMERICAN (EUROPEAN) | RANGE |

| CABLE SKIN LENGTH | |||||||

|

| CABLE SIZE |

|

|

| 2 |

|

|

|

| |

|

|

| mm |

| 1 | INCH | (25.4mm) | ||||

|

|

|

|

|

|

| |||||

|

| ||||||||||

| ) |

| |||||||||

(50 | mm | 2 | 1 | INCH | (25.4mm) | ||||||

) | |||||||||||

|

|

|

|

| 2 | 1.5 INCH (38.1mm) | |||||

(70 | mm | ) | |||||||||

2.If necessary, trim cable end of boot at groove(s) to match cable diameter. Boot must fit tightly enough to seal around outside diameter of cable. NOTE: Some boots are designed to accommodate different cable diameters without trimming. These boots do not have grooves at the cable end. Soap or other non petroleum based lubricant will help to slide the boot over the cable.

3. Slide rubber boot onto cable end. |

|

|

|

|

|

|

|

|

|

| BOOT | ||||

|

| WELDING CABLE |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SEE

ABOVE

TRIM

4.Slide the copper tube into the brass plug.

5. Insert cable into copper tube.

COPPER TUBE

6.Tighten set screw(s) to collapse copper tube. Screw(s)

must apply firm pressure against welding cable. The top of the set screw(s) will be nearly flush or below the surface of the brass plug after tightening.

7.Slide rubber boot over brass plug. The rubber boot must be positioned to completely cover all electrical surfaces after the plug is locked into the receptacle.

SET SCREW

BRASS PLUG

S18737