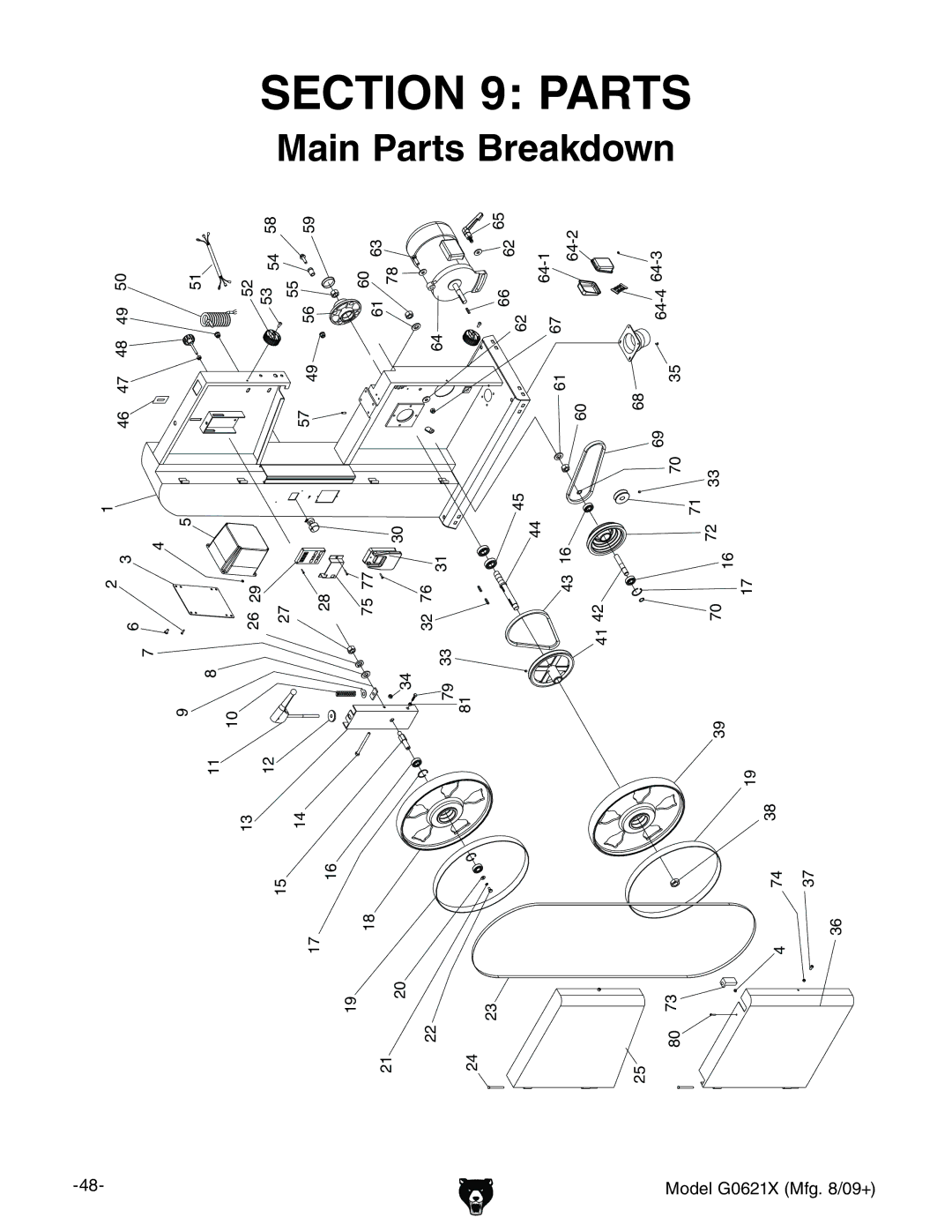

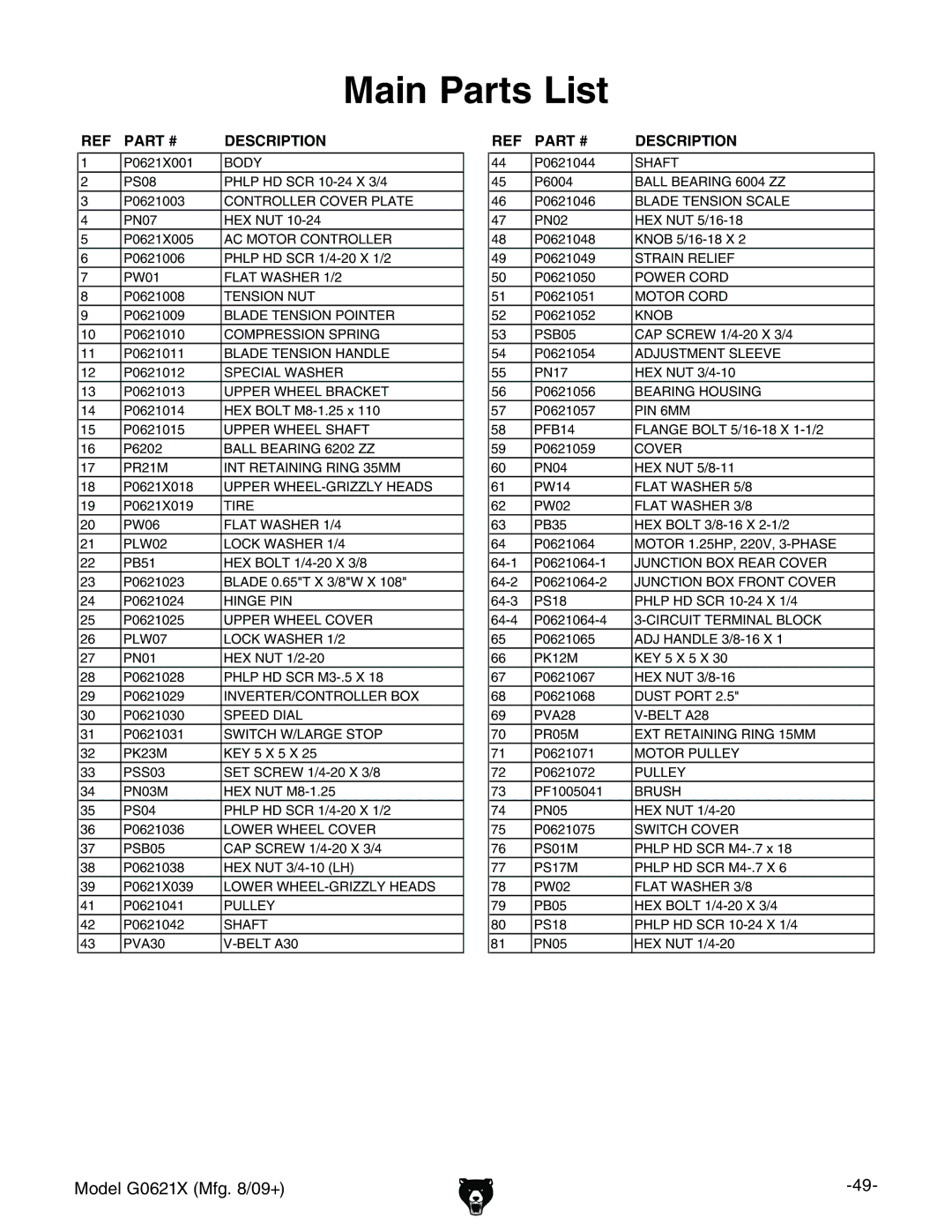

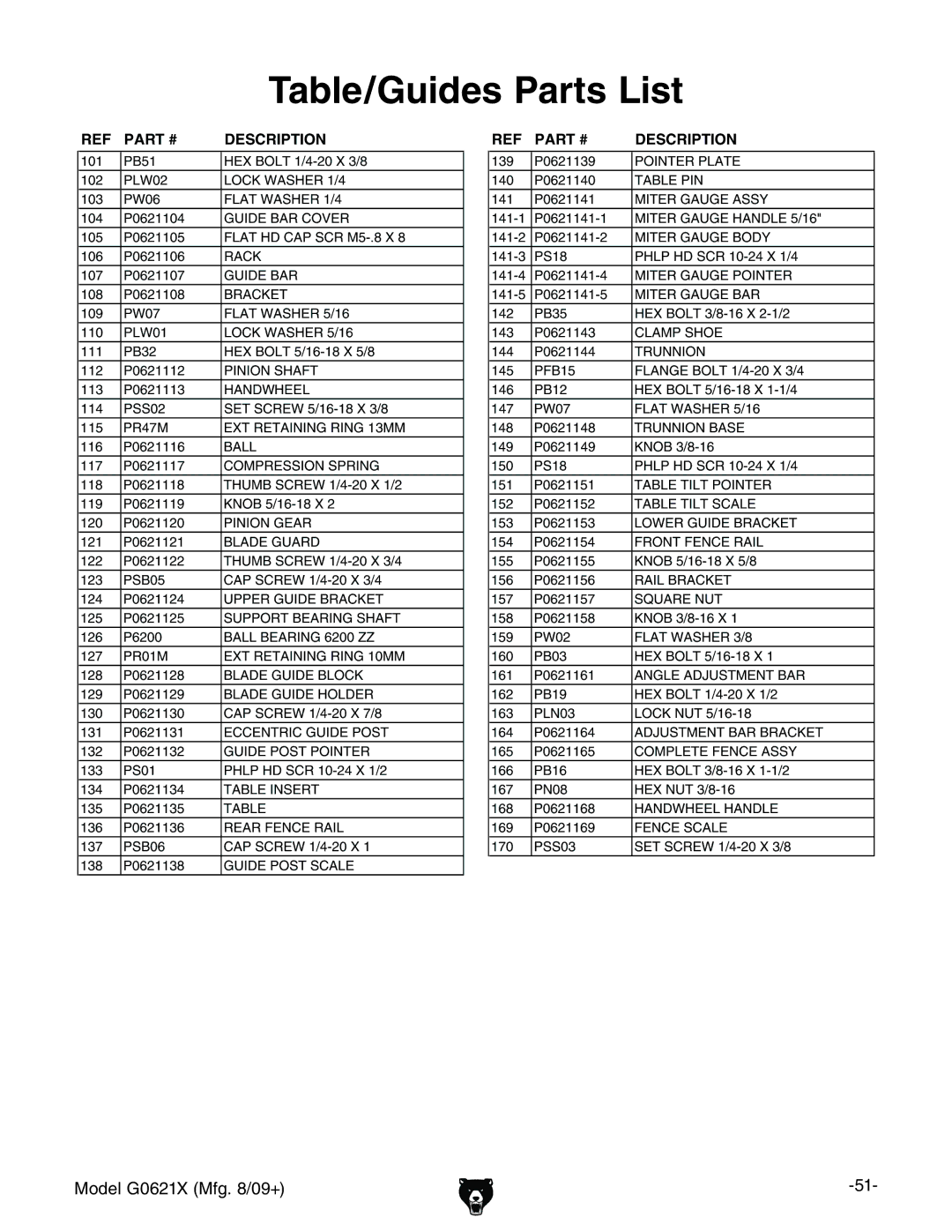

Table/Guides Parts List

REF | PART # | DESCRIPTION |

101 | PB51 | HEX BOLT |

102 | PLW02 | LOCK WASHER 1/4 |

103 | PW06 | FLAT WASHER 1/4 |

104 | P0621104 | GUIDE BAR COVER |

105 | P0621105 | FLAT HD CAP SCR |

106 | P0621106 | RACK |

107 | P0621107 | GUIDE BAR |

108 | P0621108 | BRACKET |

109 | PW07 | FLAT WASHER 5/16 |

110 | PLW01 | LOCK WASHER 5/16 |

111 | PB32 | HEX BOLT |

112 | P0621112 | PINION SHAFT |

113 | P0621113 | HANDWHEEL |

114 | PSS02 | SET SCREW |

115 | PR47M | EXT RETAINING RING 13MM |

116 | P0621116 | BALL |

117 | P0621117 | COMPRESSION SPRING |

118 | P0621118 | THUMB SCREW |

119 | P0621119 | KNOB |

120 | P0621120 | PINION GEAR |

121 | P0621121 | BLADE GUARD |

122 | P0621122 | THUMB SCREW |

123 | PSB05 | CAP SCREW |

124 | P0621124 | UPPER GUIDE BRACKET |

125 | P0621125 | SUPPORT BEARING SHAFT |

126 | P6200 | BALL BEARING 6200 ZZ |

127 | PR01M | EXT RETAINING RING 10MM |

128 | P0621128 | BLADE GUIDE BLOCK |

129 | P0621129 | BLADE GUIDE HOLDER |

130 | P0621130 | CAP SCREW |

131 | P0621131 | ECCENTRIC GUIDE POST |

132 | P0621132 | GUIDE POST POINTER |

133 | PS01 | PHLP HD SCR |

134 | P0621134 | TABLE INSERT |

135 | P0621135 | TABLE |

136 | P0621136 | REAR FENCE RAIL |

137 | PSB06 | CAP SCREW |

138 | P0621138 | GUIDE POST SCALE |

REF | PART # | DESCRIPTION |

139 | P0621139 | POINTER PLATE |

140 | P0621140 | TABLE PIN |

141 | P0621141 | MITER GAUGE ASSY |

MITER GAUGE HANDLE 5/16" | ||

MITER GAUGE BODY | ||

PS18 | PHLP HD SCR | |

MITER GAUGE POINTER | ||

MITER GAUGE BAR | ||

142 | PB35 | HEX BOLT |

143 | P0621143 | CLAMP SHOE |

144 | P0621144 | TRUNNION |

145 | PFB15 | FLANGE BOLT |

146 | PB12 | HEX BOLT |

147 | PW07 | FLAT WASHER 5/16 |

148 | P0621148 | TRUNNION BASE |

149 | P0621149 | KNOB |

150 | PS18 | PHLP HD SCR |

151 | P0621151 | TABLE TILT POINTER |

152 | P0621152 | TABLE TILT SCALE |

153 | P0621153 | LOWER GUIDE BRACKET |

154 | P0621154 | FRONT FENCE RAIL |

155 | P0621155 | KNOB |

156 | P0621156 | RAIL BRACKET |

157 | P0621157 | SQUARE NUT |

158 | P0621158 | KNOB |

159 | PW02 | FLAT WASHER 3/8 |

160 | PB03 | HEX BOLT |

161 | P0621161 | ANGLE ADJUSTMENT BAR |

162 | PB19 | HEX BOLT |

163 | PLN03 | LOCK NUT |

164 | P0621164 | ADJUSTMENT BAR BRACKET |

165 | P0621165 | COMPLETE FENCE ASSY |

166 | PB16 | HEX BOLT |

167 | PN08 | HEX NUT |

168 | P0621168 | HANDWHEEL HANDLE |

169 | P0621169 | FENCE SCALE |

170 | PSS03 | SET SCREW |

"*&" |