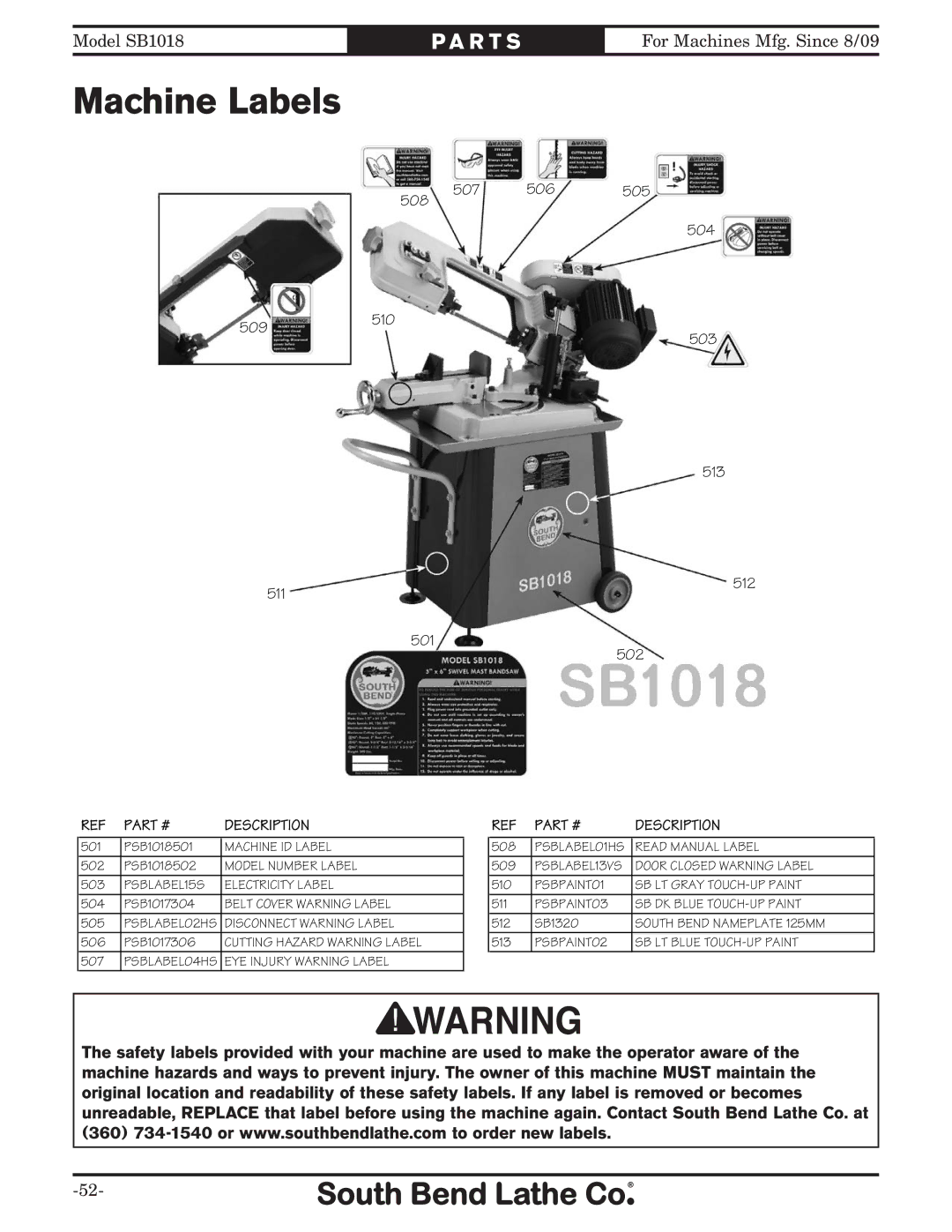

Model SB1018 | P A R T S | For Machines Mfg. Since 8/09 |

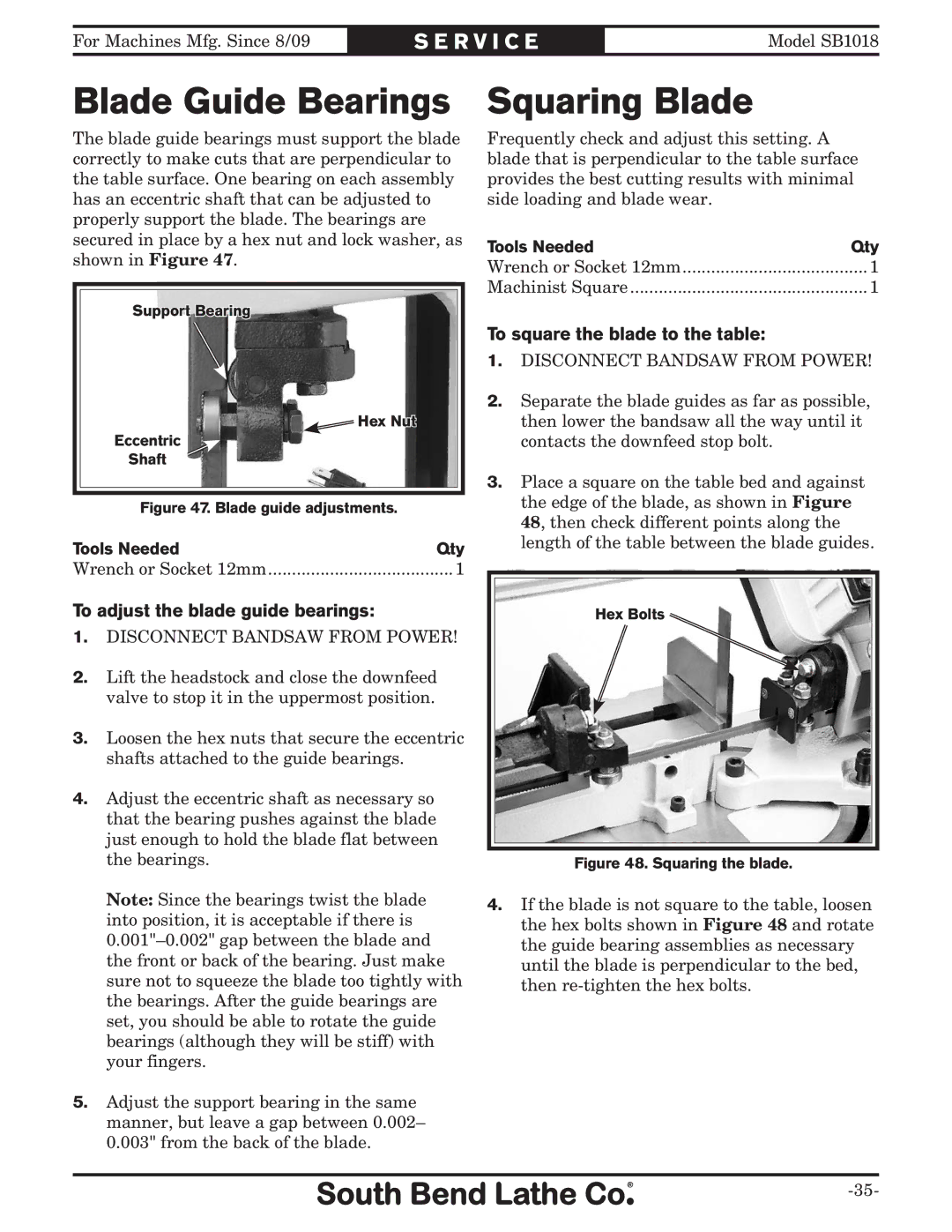

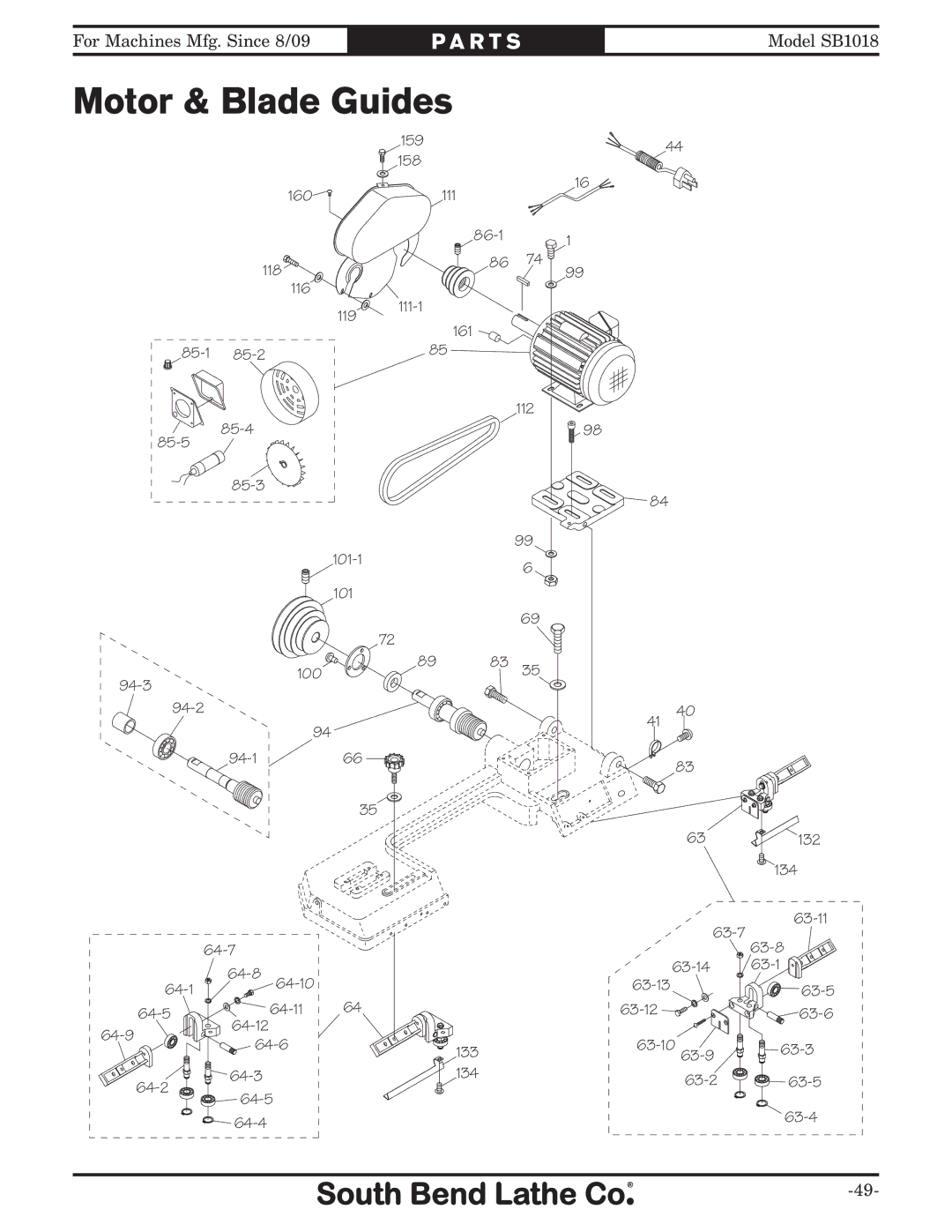

Motor & Blade Guides Parts List

REF | PART # | DESCRIPTION |

1 | PB07 | HEX BOLT |

6 | PN02 | HEX NUT |

16 | PSB1018016 | MOTOR CORD 18G 3W |

35 | PW02 | FLAT WASHER 3/8 |

40 | PS06 | PHLP HD SCR |

41 | PSB1017041 | WIRE CLIP |

44 | PSB1018044 | POWER CORD 18G 3W |

63 | PSB1018063 | REAR BLADE GUIDE ASSEMBLY |

REAR BLADE GUIDE BRACKET | ||

LEFT GUIDE SHAFT | ||

RIGHT GUIDE SHAFT | ||

GUIDE EXT RETAINING RING | ||

P6000ZZ | BALL BEARING 6000ZZ | |

BEARING PIN 10 X 36 | ||

PN11 | HEX NUT | |

PLW04 | LOCK WASHER 3/8 | |

DEFELCTOR PLATE | ||

PFH19 | FLAT HD SCR | |

REAR BLADE GUIDE ARM | ||

PB12 | HEX BOLT | |

PLW01 | LOCK WASHER 5/16 | |

PW07 | FLAT WASHER 5/16 | |

64 | PSB1018064 | FRONT BLADE GUIDE ASSEMBLY |

FRONT BLADE GUIDE BRACKET | ||

LEFT GUIDE SHAFT | ||

RIGHT GUIDE SHAFT | ||

GUIDE EXT RETAINING RING | ||

P6000ZZ | BALL BEARING 6000ZZ | |

BEARING PIN 10 X 36 | ||

PN11 | HEX NUT | |

PLW04 | LOCK WASHER 3/8 | |

FRONT BLADE GUIDE ARM | ||

PB12 | HEX BOLT | |

PLW01 | LOCK WASHER 5/16 | |

PW07 | FLAT WASHER 5/16 | |

66 | PSB1018066 | BLADE GUIDE KNOB BOLT |

REF | PART # | DESCRIPTION |

69 | PB24 | HEX BOLT |

72 | PSB1017072 | BEARING COVER |

74 | PK12M | KEY 5 X 5 X 30 |

83 | PB78 | HEX BOLT |

84 | PSB1017084 | MOTOR MOUNT PLATE |

85 | PSB1018085 | MOTOR 1/2HP 110/220V 1PH |

CORD STRAIN RELIEF | ||

MOTOR FAN COVER | ||

MOTOR FAN | ||

PC200G | S CAPACITOR 200M 125V | |

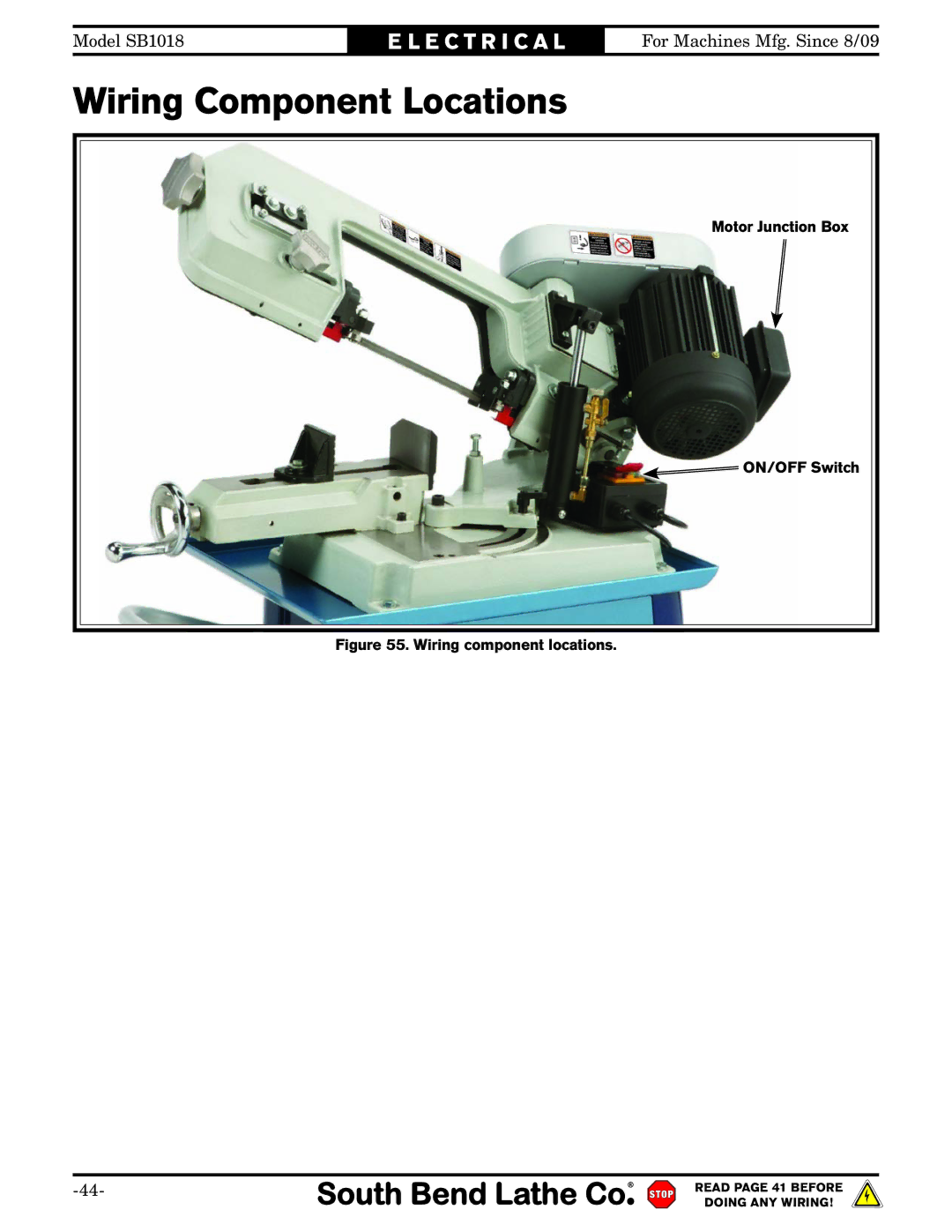

MOTOR JUNCTION BOX | ||

86 | PSB1017086 | MOTOR PULLEY |

PSS17 | SET SCREW | |

89 | PSB1017089 | OIL SEAL TC 15 X 35 X 7 |

94 | PSB1017094 | WORM GEAR SHAFT ASSEMBLY |

WORM GEAR SHAFT | ||

P6202ZZ | BALL BEARING 6202ZZ | |

BUSHING | ||

98 | PCAP25 | CAP SCREW |

99 | PW07 | FLAT WASHER 5/16 |

100 | PFH37 | FLAT HD SCR |

101 | PSB1017101 | WORM GEAR PULLEY |

PSS18 | SET SCREW | |

111 | PSB1017111 | BELT COVER |

BELT COVER PANEL | ||

112 | PVA22 | |

116 | PW06 | FLAT WASHER 1/4 |

118 | PB19 | HEX BOLT |

119 | PSB1018119 | PLASTIC WASHER |

132 | PSB1017132 | REAR GUIDE GUARD |

133 | PSB1017133 | FRONT GUIDE GUARD |

134 | PS23 | PHLP HD SCR |

158 | PW06 | FLAT WASHER 1/4 |

159 | PB19 | HEX BOLT |

160 | PS18 | PHLP HD SCR |

161 | PSB1018161 | PLASTIC CUP |