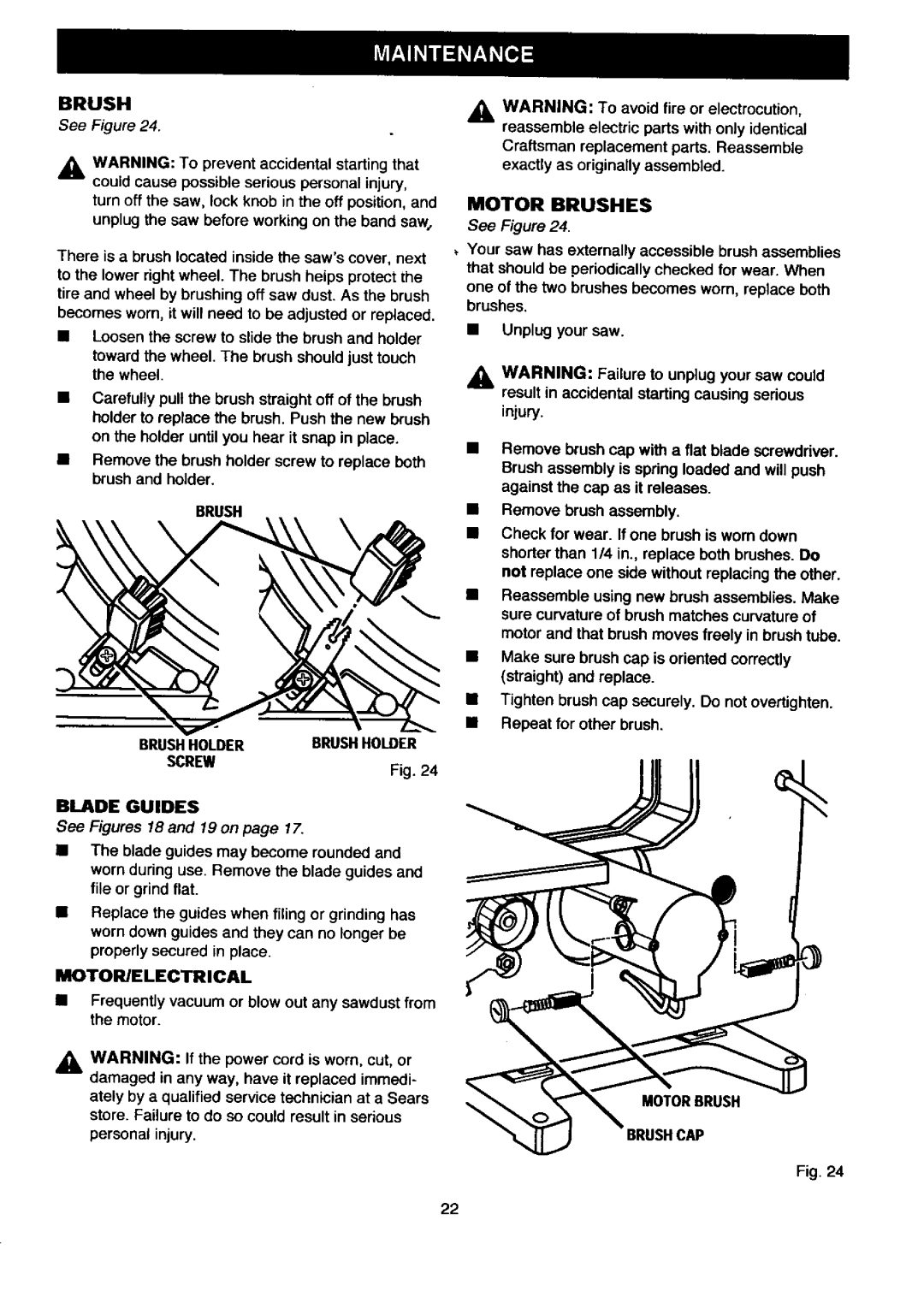

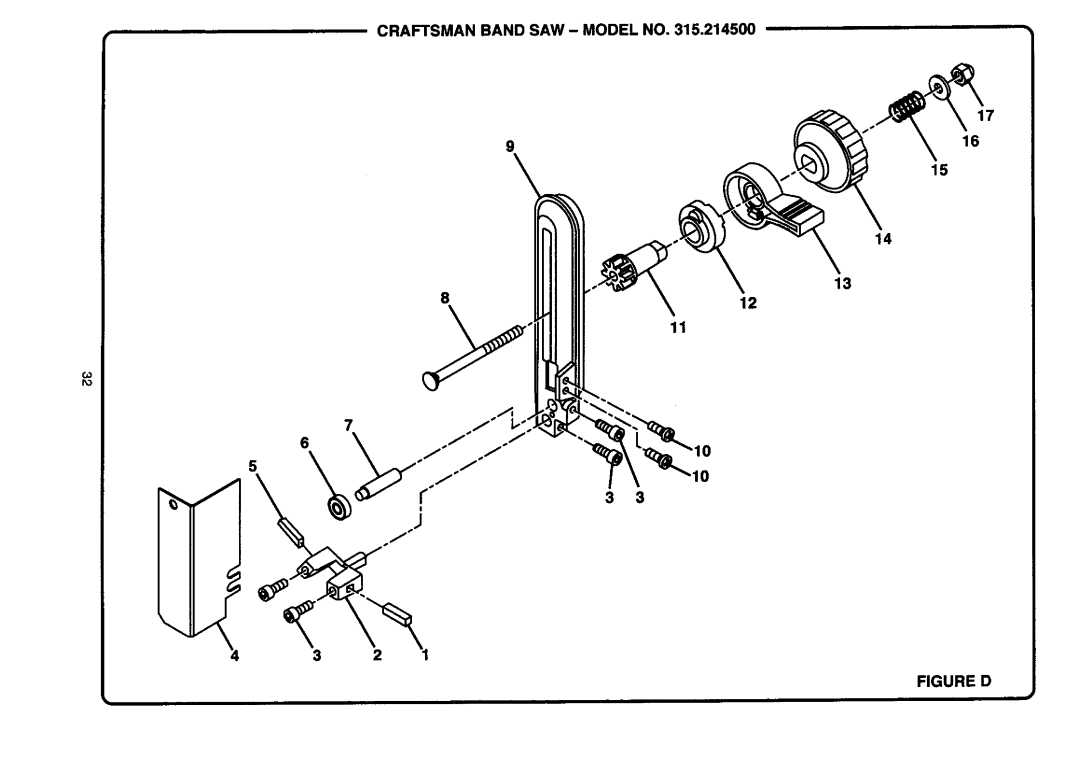

To Adjust •lade Guides

Theblade guides help keep the blade from twisting and binding. Letting the blade teeth hit the blade guides while using the band saw will ruin the blade. The set of teeth and the sharpened edge of teeth would be damaged by hitting the blade guides. Proper adjustment of the upper and lower blade guides will , prevent this from happening.

•Loosen the two blade guide screws that lock the upper blade guides. Press the two guides evenly near the sides of the blade leaving about 0.004 in. from the blade. (0.004 is the thickness of a dollar bill.) Do not pinch the blade. Make sure one guide is not further away from the blade than the other. Release the guides and tighten both screws securely.

•Repeat this prOcedure on the lower blade guides located under the table. See Figure 19.

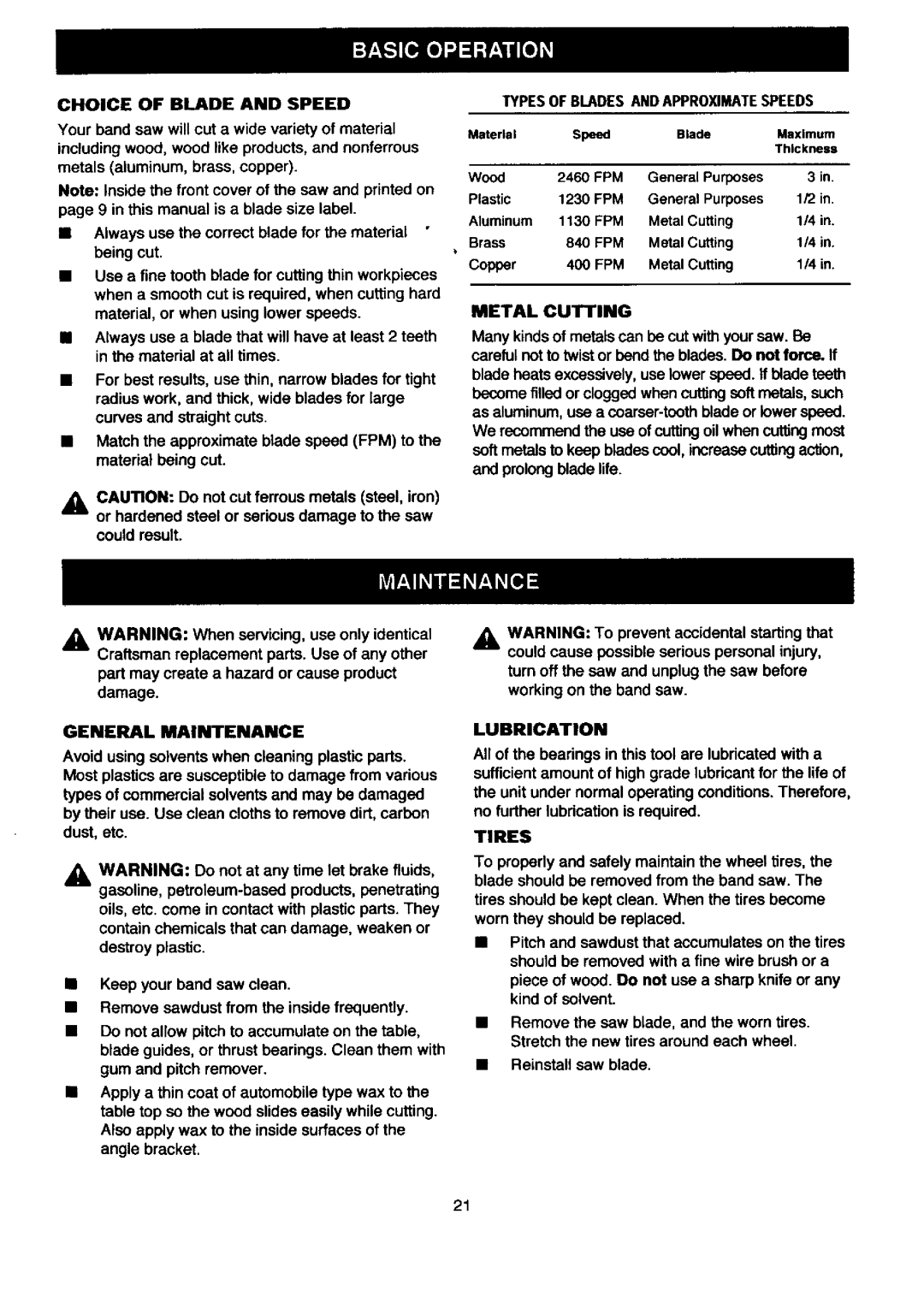

This band saw is designed to cut wood, wood compo- sition prOducts, plastic, and nonferrous metals (alumi- num, brass, copper).

_1_ CAUTION: Do not cut ferrous metals (steel, iron) or hardened steel or serious damage to the saw

could result.

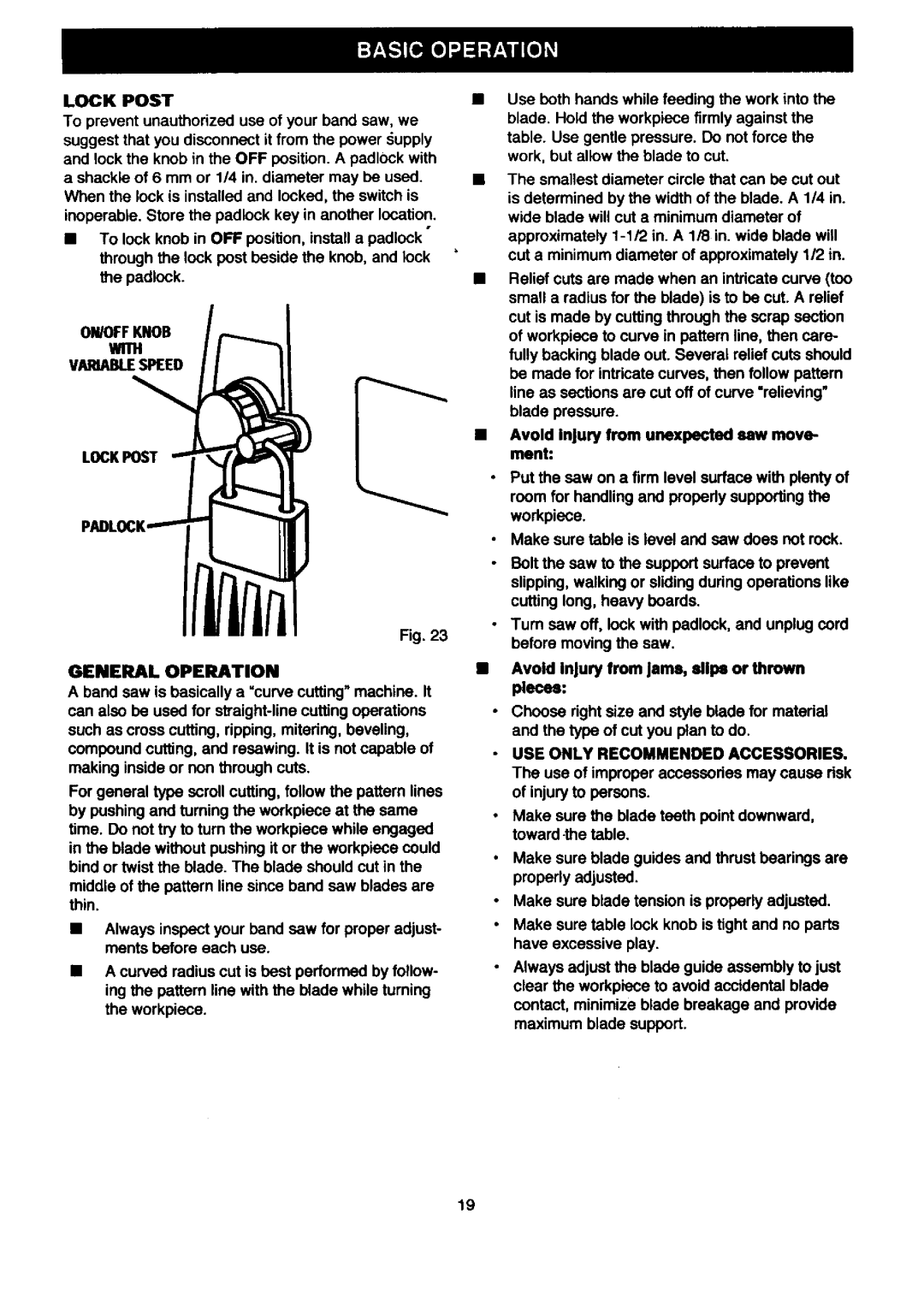

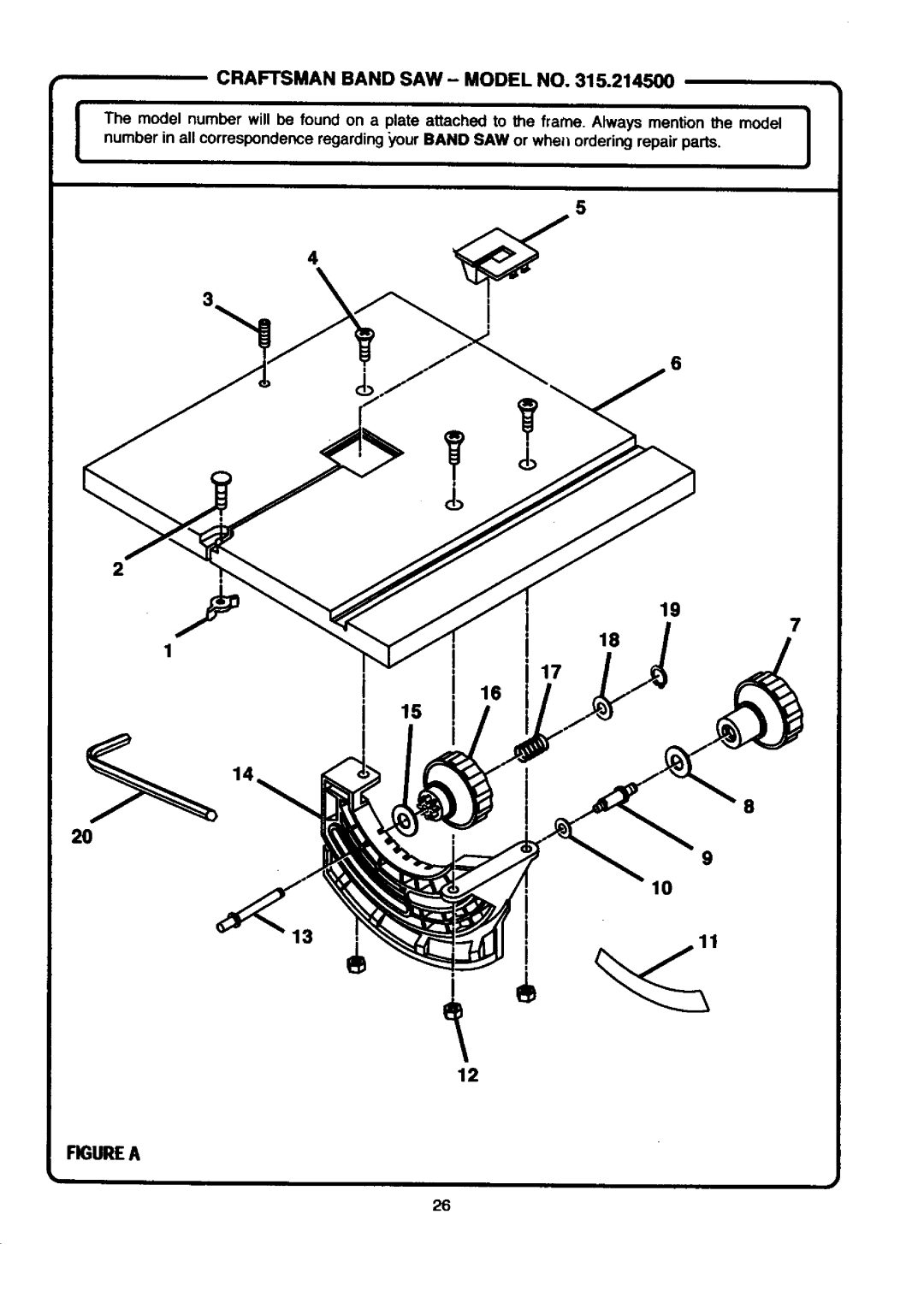

ON/OFF KNOB

See Figure 21.

•Pull the knob out to turn the saw ON.

Note: The motor will gradually come up to speed after the saw is turned ON.

•Push the knob in to turn the saw OFF.

PUSHOFF

PULLON

ONIOEFKNOB

WITH

VARIABLESPEED

Fig. 21

BLADE GUARD REMOVED

FOR CLARIFICATION ONLY

THRUST

THRUST

BEARINGSCREW

BLADEGUIDE

SCREW

SCREW

BLADEGUIDES

Fig. 20

VARIABLE SPEED

See Figure 22.

The variable speed control may be adjusted to the approximate speeds identified on the On/Off knob label. Turn the knob clockwise or to the right to increase speed, up to 3000 FPM (feet per minute). Turn the knob counterclockwise or to the left to reduce speed as low as 500 FPM (feet per minute).

TOINCREASESPEED

ON/OFFKNOB

WiTH

VARIABLESPEED

SPEED | Fig. 22 |

18