Bevel Cut

A cutting operation made with an angled table.

Crosscut

A cutting operation made across the grain or the width of the workpiece.

Compound Cut

A compound cut is a cut made using a miter angle " and a bevel angle at the same time.

FPM

Feet per minute. Used in reference to surface speed of blade.

Ferrous Metal

Metal that contains iron; such as steel.

Freehand (for band saw)

Performing a cut without the workpiece properly supported on the table.

Gum

A sticky, sap based residue from wood products.

Kerf

The material removed by the blade in a through cut or the slot produced by the blade in a nonthrough or partial cut.

Leading End

The end of the workpiece pushed into the cuffing tool first.

Nonferrous Metal

Metal that does not contain iron; such as aluminum, brass, and copper.

Miter Cut

A cutting operation made with the edge of the workpiece at any angle to the blade other than 90 degrees.

Push Stick

A device used to feed the workpiece through the saw blade during narrow cuffing operations. It helps keep, the operator'shands well away from the blade.

Reeaw

A cutting operation to reduce the thickness of the workpiece to make thinner pieces.

Resin

A sticky, sap based substance.

Ripping

A cutting operation along the length of the workpiece.

Saw Blade Path

The area directly in line

Set

The distance that the tip of the saw blade tooth is bent (or set) outward from the face of the blade.

Throwing of a workpiece in a manner similar to a kickback. Usually associated with a cause other than the kerr closing, such as a workpiece being dropped into the blade, or being carelessly placed in contact with the blade.

Through Sawing

Any cutting operation where the blade extends completely through the workpiece.

Workplece

The item on which the cuffing operation is being done.

The surfaces of a workpiece are commonly referred to as faces, ends, and edges.

Worktable

The surface on which the workpiece rests while performing a cutting operation.

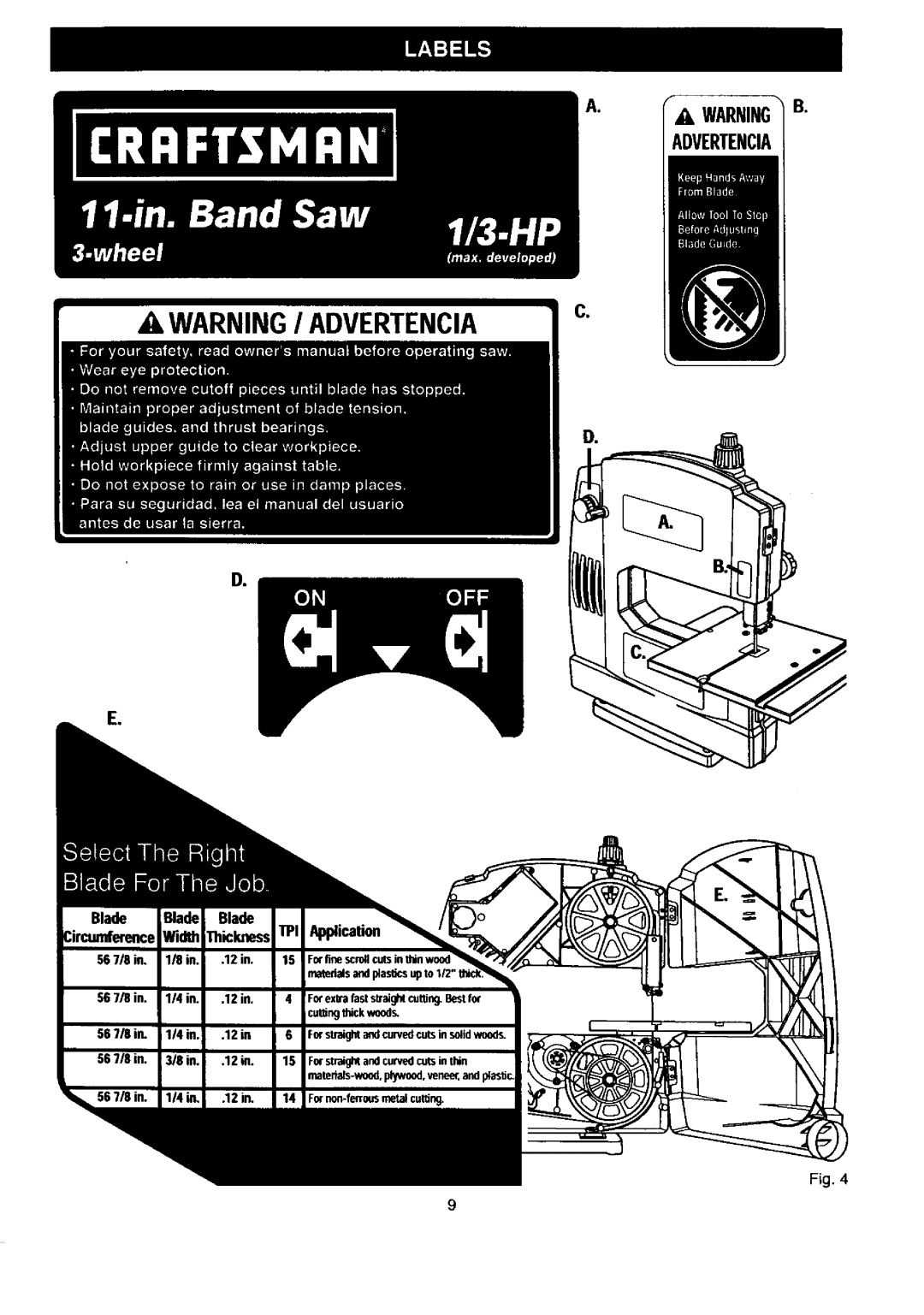

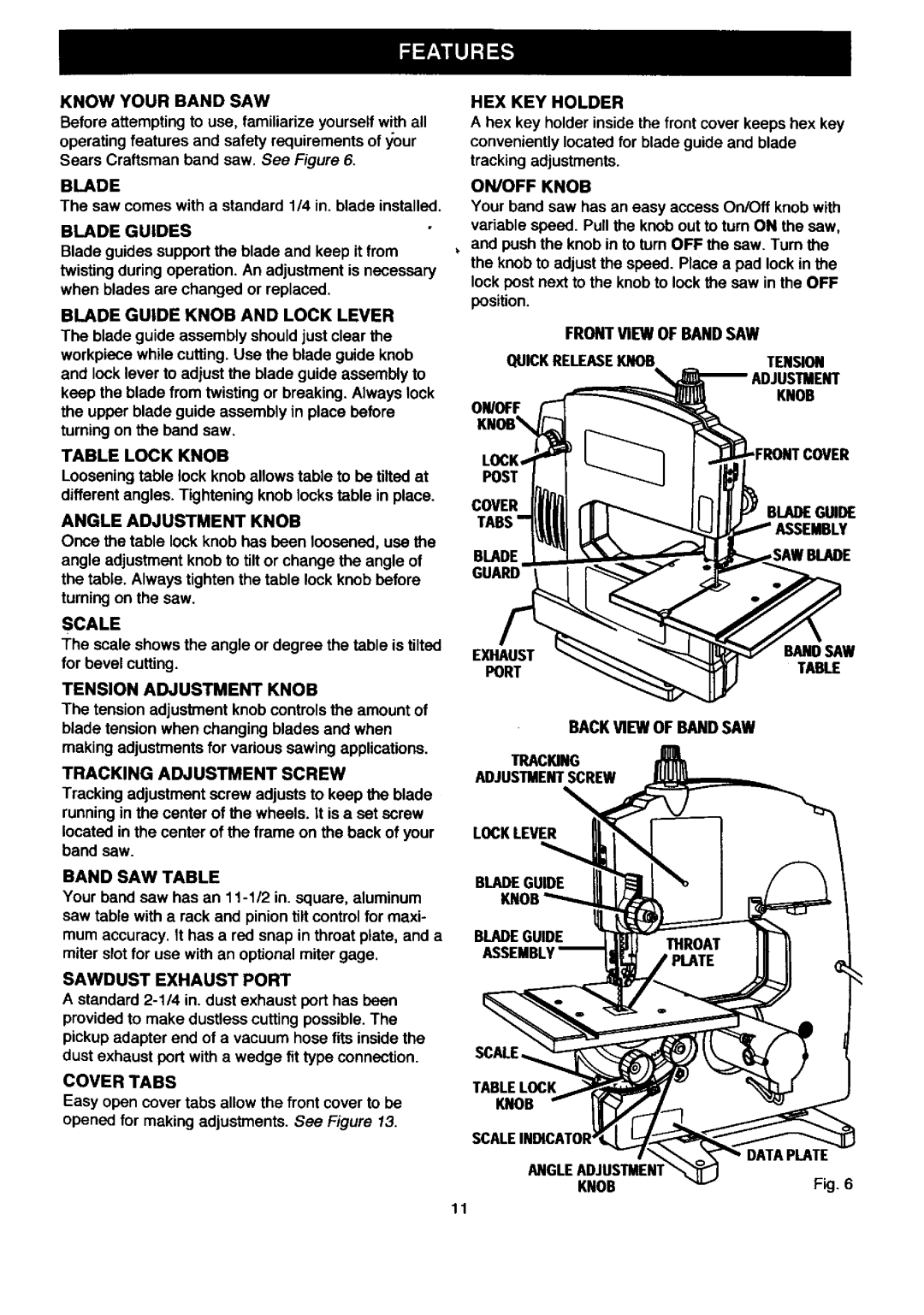

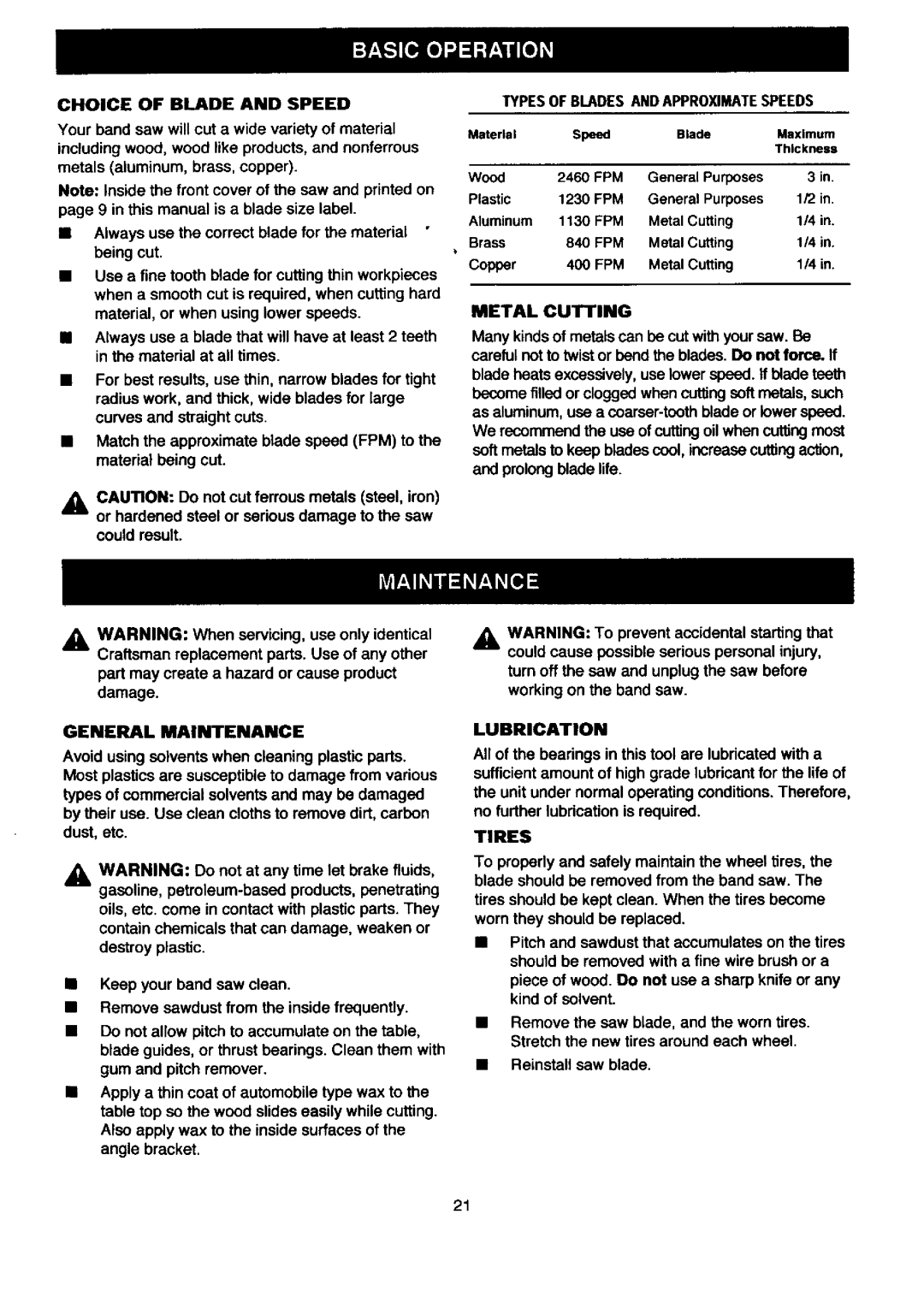

Blade Width | 118 in. to 3/8 | in. | |

Blade Length | in. | ||

Capacities: |

|

| |

Frame | to Blade | 11 in. | |

Under | guide | in. | |

Table Size | in. | ||

Table Tilt | 0 ° - 45 ° |

Input | 120 V, 4.2 amp 60 Hz, AC only |

No Load Speed | |

Overall Dimensions | |

Net Weight | 28 Ibs. |