Operating Instructions Instructions d’Utilisation Manual de Instrucciones

Notes

Notas

See Warranty on page 6 for important information about commercial use of this product.

Operating Instructions

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or prop- erty damage! Retain instructions for future reference.

Detail Spray Gun

Detail Spray Gun

Description

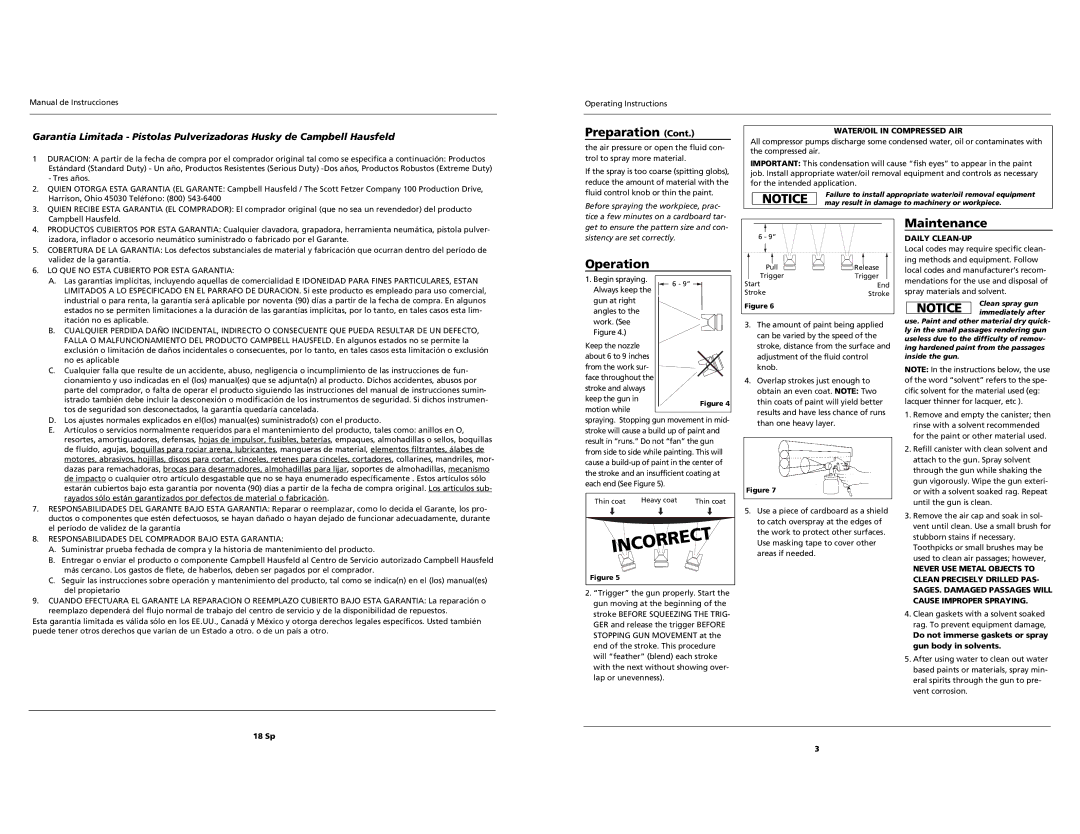

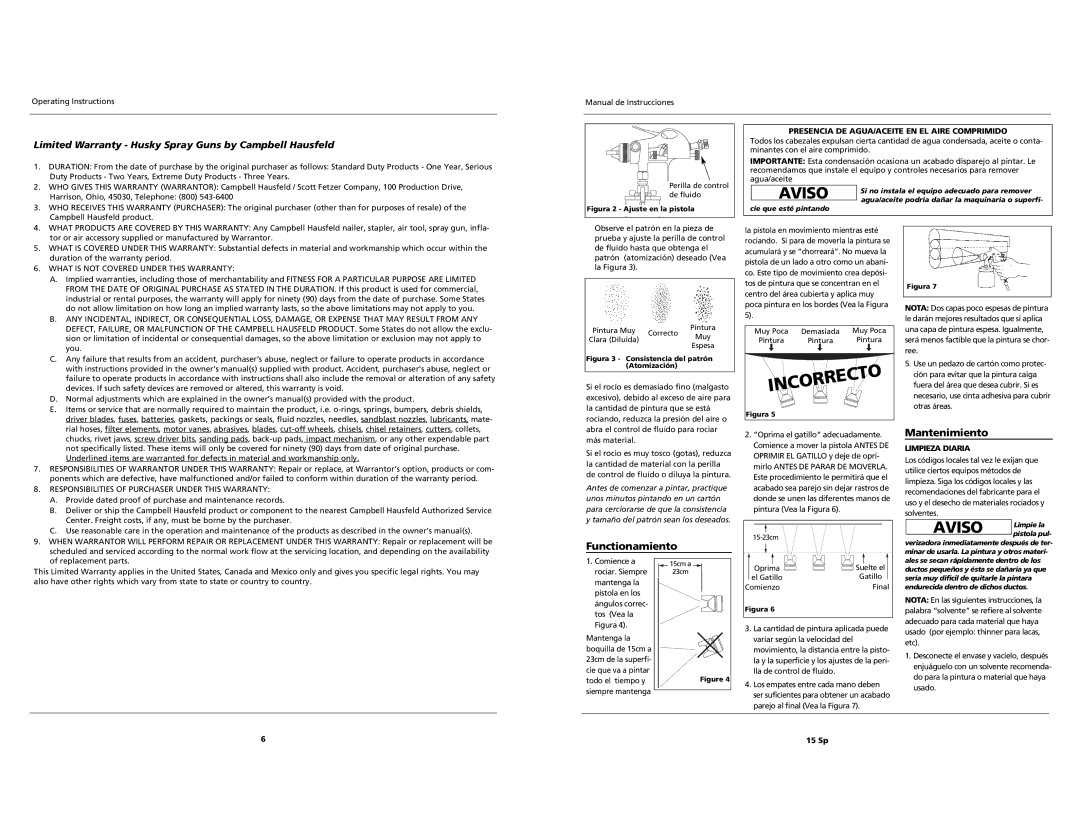

A conventional siphon feed detail spray gun designed to spray all light to medi- um viscosity materials. It has fluid and pattern controls and is supplied with an 8 oz. material cup. The compact design makes this spray gun handy for detail,

Safety Guidelines

This manual contains information that is very important to know and under- stand. This information is provided for SAFETY and to PREVENT EQUIPMENT PROBLEMS. To help recognize this infor- mation, observe the following symbols.

Danger indicates

! DANGER an imminently haz- ardous situation which, if not avoided, WILL result in death or serious injury.

Warning indicates ! WARNING a potentially haz-

ardous situation which, if not avoided, COULD result in death or serious injury.

| Caution indicates a | |

! CAUTION | ||

potentially haz- |

ardous situation which, if not avoided, MAY result in minor or moderate injury.

Notice indicates !NOTICE important infor-

mation, that if not followed, may cause damage to equipment.

Unpacking

After unpacking the product, inspect carefully for any damage that may have occurred during transit. Make sure to tighten fittings, bolts, etc., before putting unit into service.

Do not operate ! WARNING tool if damaged

during shipping, handling or use.

Damage could result in bursting and cause injury or property damage.

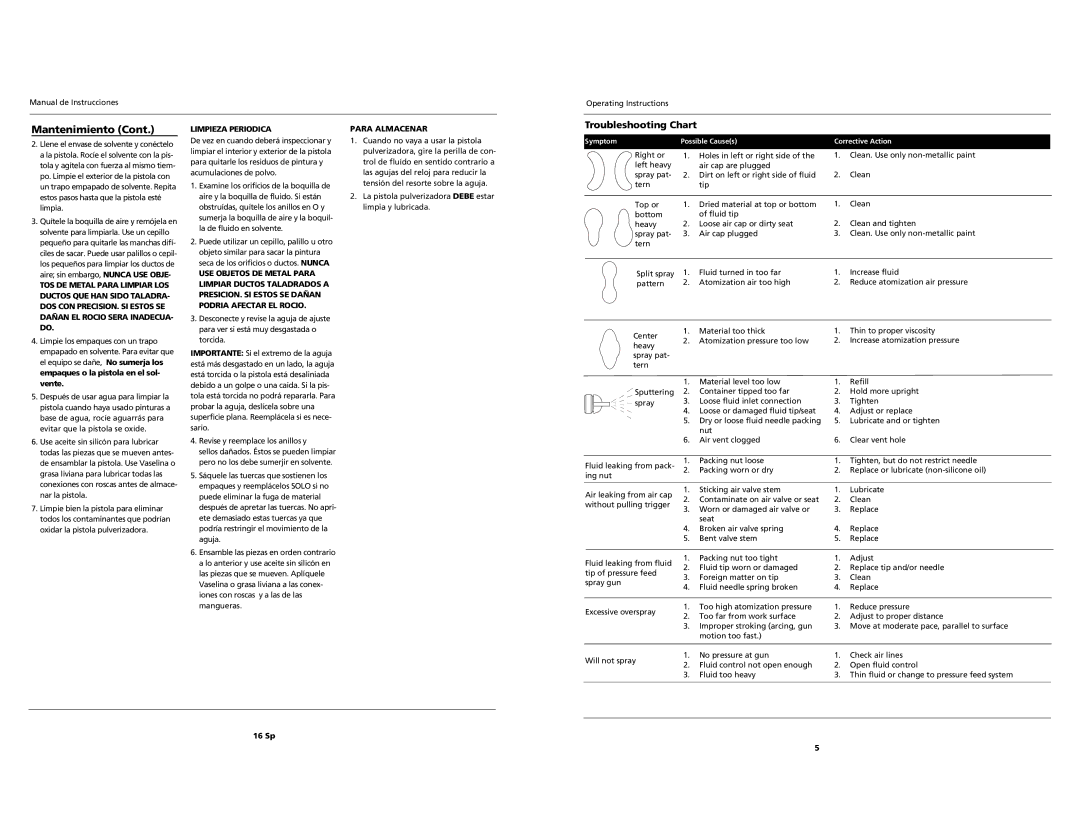

Spray Gun Terms

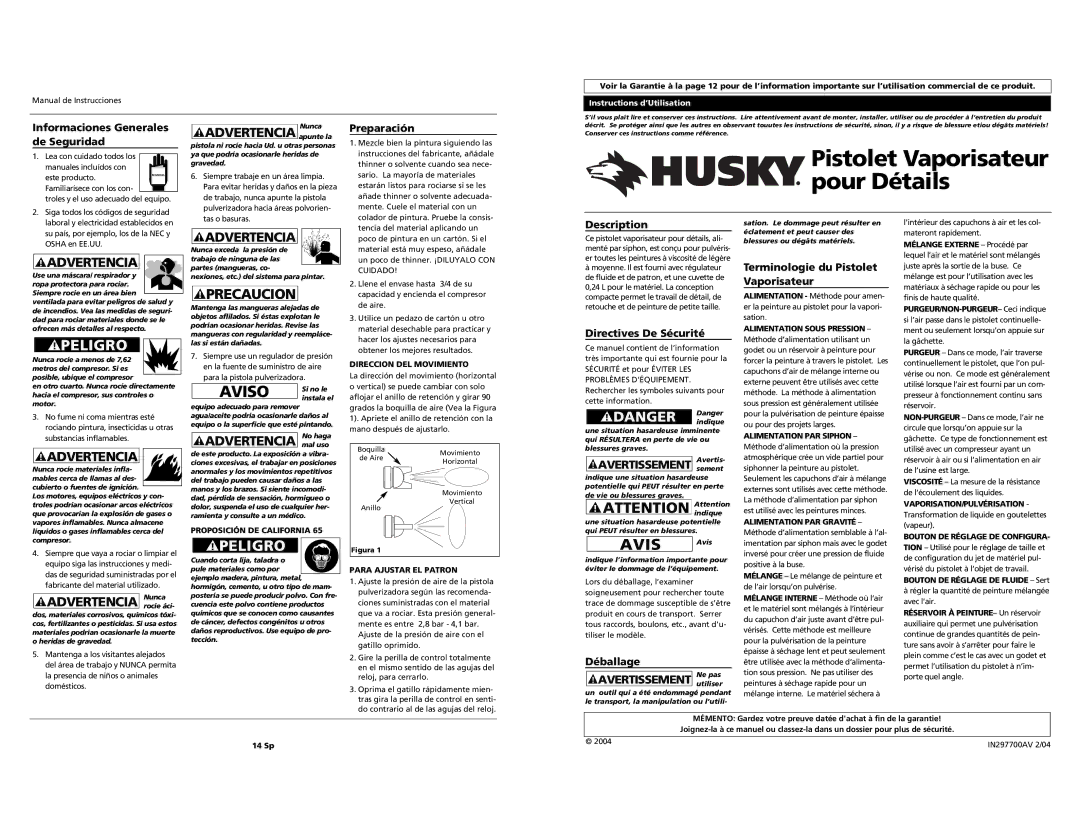

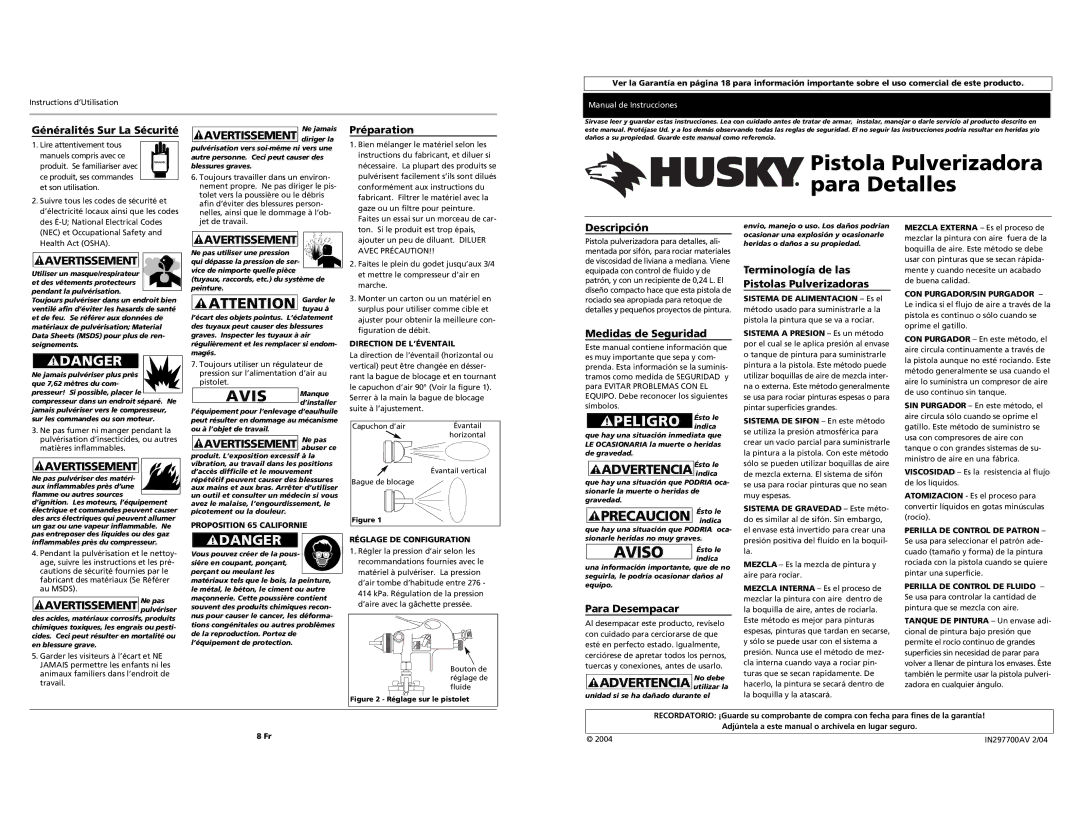

FEED – Method used to bring paint into the gun for spraying.

PRESSURE FEED – Method of paint feed where a canister or paint tank is pressurized to force paint to the gun. Either internal or external mix air caps are used with this method. Pressure feed is generally used for spraying heavy bod- ied paints or for large size projects.

SIPHON FEED – Method of paint feed where atmospheric pressure creates a partial vacuum to siphon paint to the gun. Only external mix air caps are used with this method. Siphon feed is used with light bodied paints.

GRAVITY FEED – Method of paint feed similar to the siphon feed method. However, the cup is inverted to create a positive fluid pressure at the nozzle.

MIX – The mixing of paint and air when spraying.

INTERNAL MIX – Process where the air and paint are mixed inside the air cap just before being sprayed. This method is best for heavy bodied, slow drying paints and can only be used with the pressure feed method. Do not use fast drying paints with internal mix. The paint will dry inside and quickly clog the air cap.

EXTERNAL MIX – Process where the air and paint are mixed just after leav- ing the nozzle. This type of mix should be used for fast drying paints and when a high quality finish is needed.

BLEEDER – In this mode, air passes con- tinuously through the gun whether spraying or not. This mode is generally used when the air is supplied by a con- tinuously running compressor that does not have a tank.

VISCOSITY – A measurement of the resistance of the flow of a liquid.

ATOMIZATION - Conversion of liquid to spray droplets (mist).

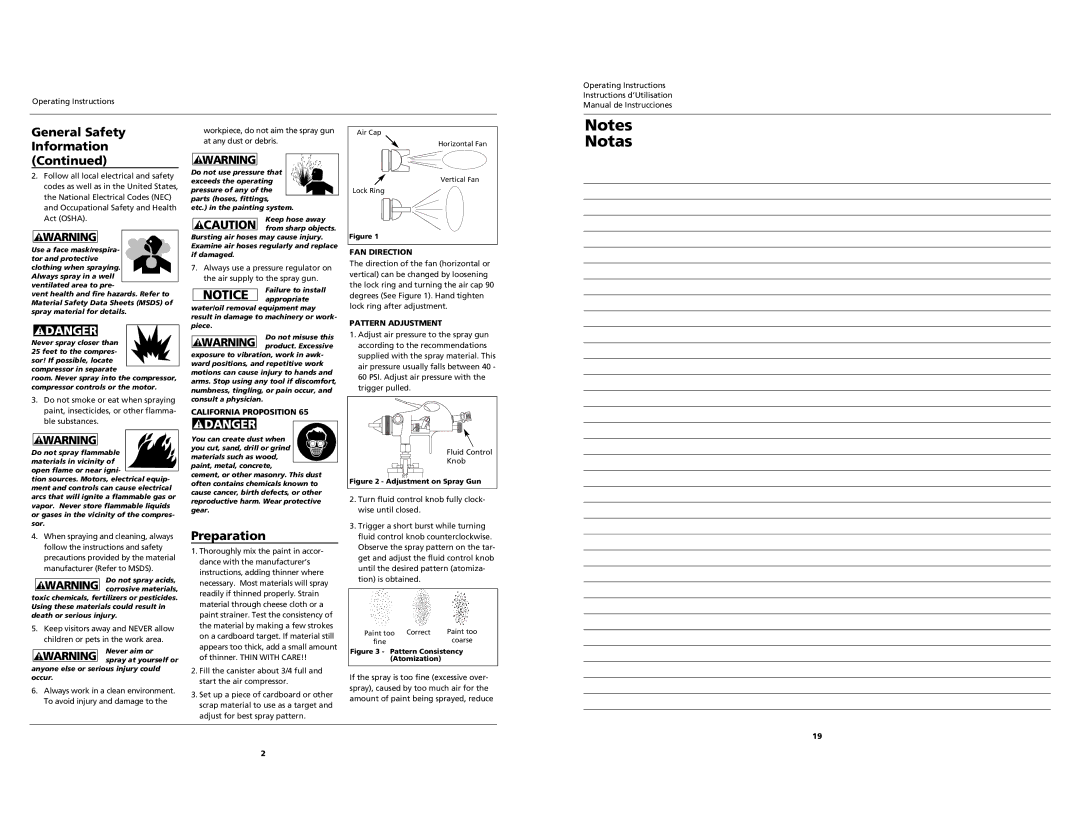

PATTERN CONTROL KNOB – Used to form the proper pattern (size and shape) of paint as it is sprayed from the gun to the work piece.

FLUID CONTROL KNOB – Used to con- trol the amount of paint being mixed with air.

PAINT TANK – An auxiliary pressurized paint reservoir that allows continuous spraying of large amounts of paint with- out stopping for refills as with a canister. It also allows using the spray gun at any angle or orientation.

General Safety

Information

1. Read all manuals included

with this product careful-

ly. Be thoroughly familiar MANUAL with the controls and the proper use of the equipment.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

© 2004 | IN297700AV 2/04 |