Clean Up

Unpainted surfaces may be coated with a waxy oil to protect them from corrosion during ship- ment. Remove this waxy oil with a solvent clean- er or

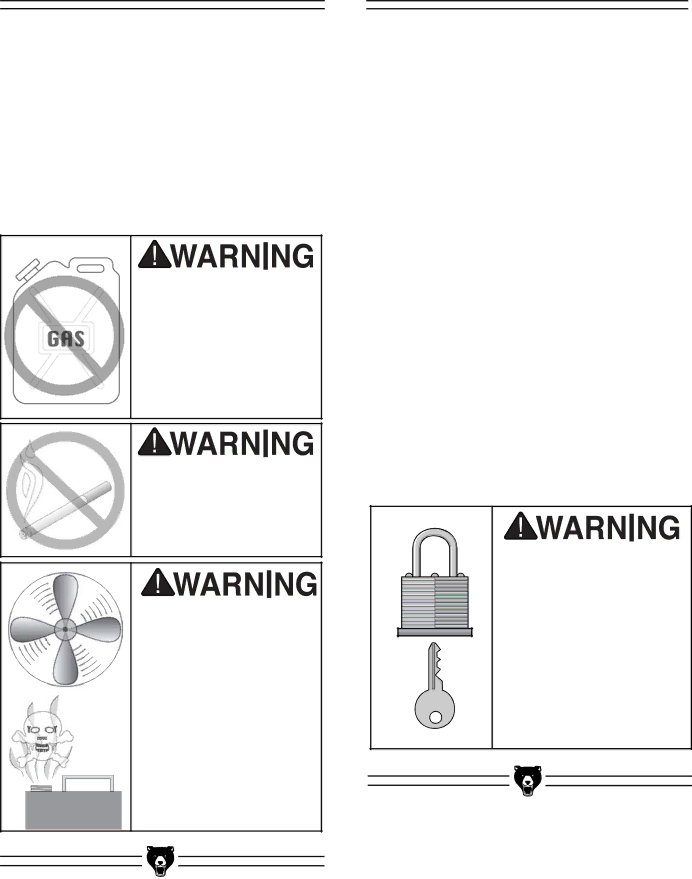

Gasoline and petroleum products have low flash points and could explode if used to clean machin- ery. DO NOT use gaso- line or petroleum prod- ucts to clean the machin- ery.

Smoking near solvents could ignite an explosion or fire and cause serious injury. DO NOT smoke while using solvents.

Lack of ventilation while using solvents could cause serious personal health risks, fire, or environmental hazards. Always work in a well ventilated area to pre- vent the accumulation of dangerous fumes. Supply the work area with a constant source of fresh air.

G0518 Drum / Flap Sander

Site Considerations

Weight Load

The Model G0518 is a medium weight load with a small footprint. Most shop floors should be suffi- cient to carry the weight of the machine. Reinforce the floor if you question its ability to support the weight.

Working Clearance

Working clearances can be thought of as the dis- tances between machines and obstacles that allow safe operation of every machine without lim- itation. Consider existing and anticipated machine needs, size of material to be processed through each machine, and space for auxiliary stands and/or work tables. Also consider the relative position of each machine to one another for effi- cient material handling.

Lighting And Outlets

Lighting should be bright enough to eliminate shadow and prevent eye strain. Electrical circuits should be dedicated or large enough to handle the amperage draw. Outlets should be located near each machine so power or extension cords are clear of

Unsupervised children and visitors inside your shop could receive seri- ous personal injury. Ensure child and visitor safety by keeping all entrances to the shop locked at all times. DO NOT allow unsupervised children or visitors in the shop at any time.