Air Line |

| Dust Collection |

|

|

|

|

|

|

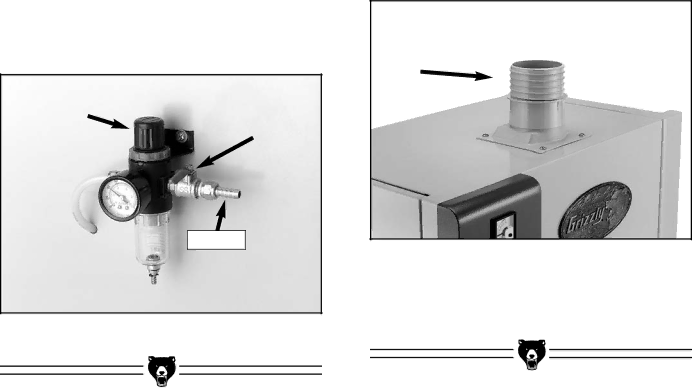

To hook up the air line:

1.Connect the hose from your air compressor to the air inlet (Figure 7) on the regulator.

2.Make sure the red handle on the regulator is in the open position (parallel with the air inlet).

3.Lift the black regulator knob (Figure 7) and adjust it until the air pressure gauge reads 75 PSI.

4.Push the regulator knob down until it snaps.

Black |

|

|

Regulator |

| Red Handle |

Knob |

| (Closed Position) |

|

|

|

Air Inlet

Figure 7. Air inlet located on regulator.

An efficient and clean dust collection system is essential to the proper function of the sander. Ensuring a healthy work environment is also dependent upon cleaning and maintaining your dust collection system.

To hook up the dust collection system:

1.Install the 4" dust port (Figure 8) on the mounting locations at the top of the sanding unit with the supplied

Figure 8. Dust collection hook-up.

2.Clamp a hose from your dust collection sys- tem to the dust port.

G0527 18" Wide Belt Sander |