Belt Oscillation

NOTICE

The oscillation adjustments have been per- formed at the factory and should require no further attention. However, we recommend verifying the settings.

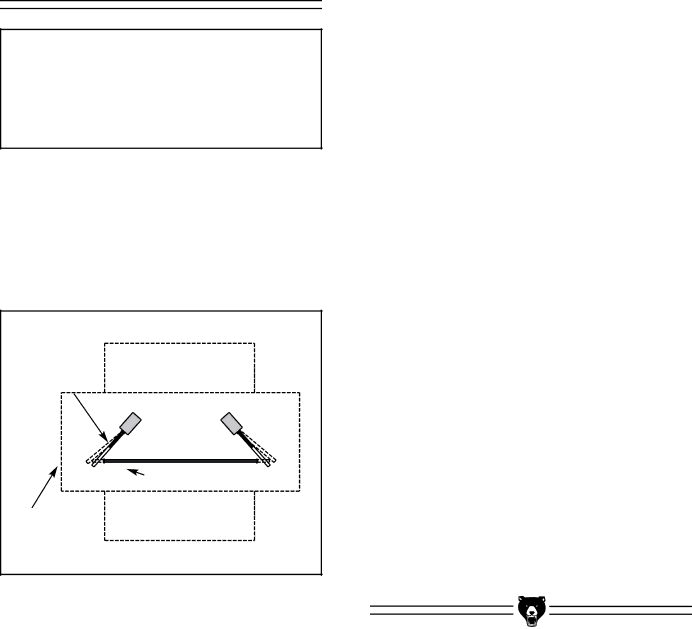

When the oscillation is correctly adjusted, the sanding belt oscillates to the left and to the right at the same speed and without coming into con- tact with the limit switches. If the sanding belt oscillates too far to the left or right, making con- tact with the limit switches as shown in Figure 19, the emergency braking system will activate.

Limit Switches |

Sanding Belt |

Sander Outline |

(Top View) |

Figure 19. Improper oscillation.

To check the sanding belt oscillation:

1.Be sure the sanding belt is properly installed and the belt tension switch is set to tension the belt.

2.With safety glasses on and the left access door still open, press the SANDING BELT START Button.

3.Watch as the belt either oscillates back and forth continuously, or tracks into one of the two limit switches, triggering the emergency brake.

—If the belt tracks into either limit switch, adjust the two air flow adjustment knobs independently of one another until the the belt no longer hits the limit switches. Trial and error may be necessary.

—If the oscillation time is not consistent from one direction to the other, the air cylinder arm needs to be lengthened or shortened according to the following guidelines:

•If the belt tracks away from the air cylinder faster, shorten the arm.

•If the belts tracks towards the air cylin- der faster, lengthen the arm.

—If the oscillation rate needs to be increased or decreased, adjust the air flow adjustment

G0527 18" Wide Belt Sander |