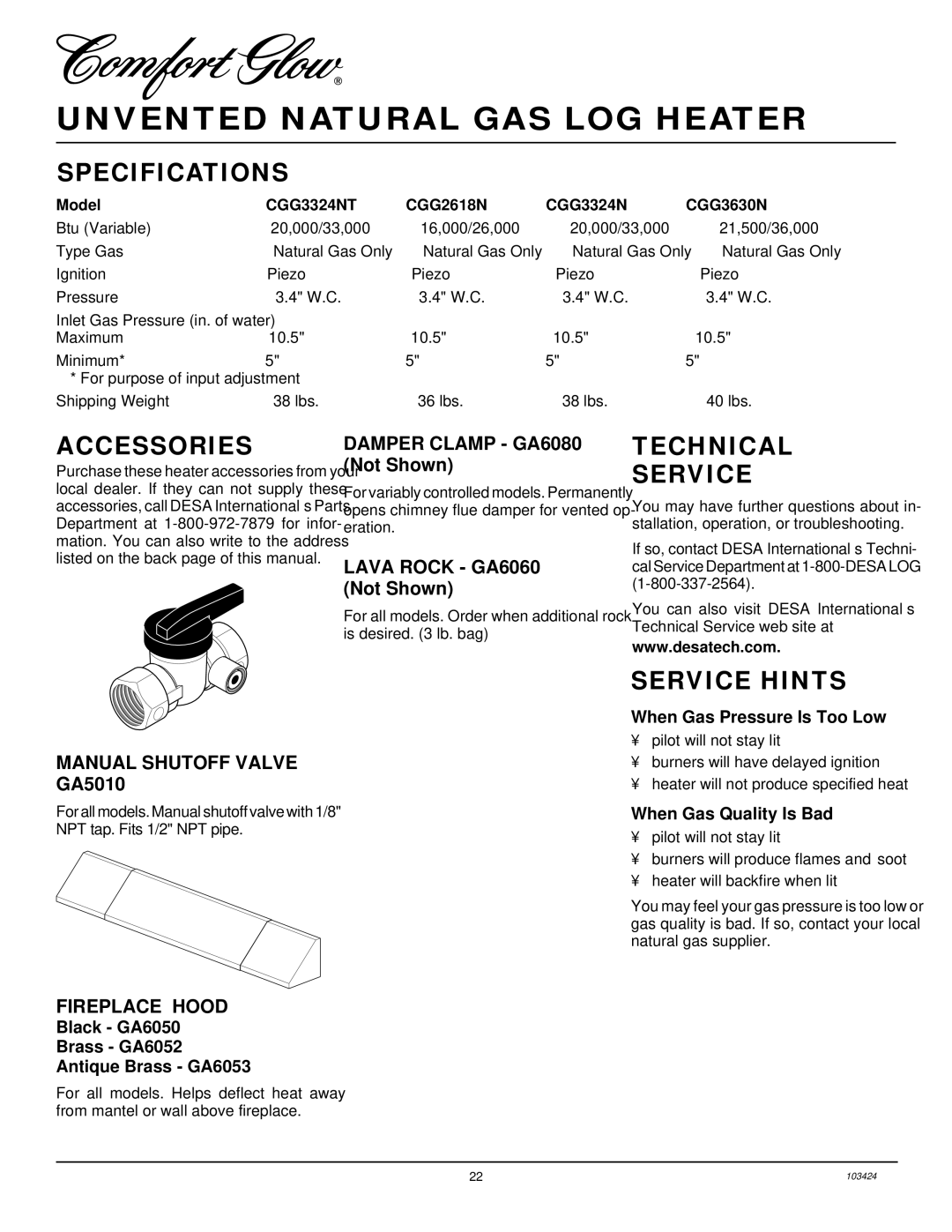

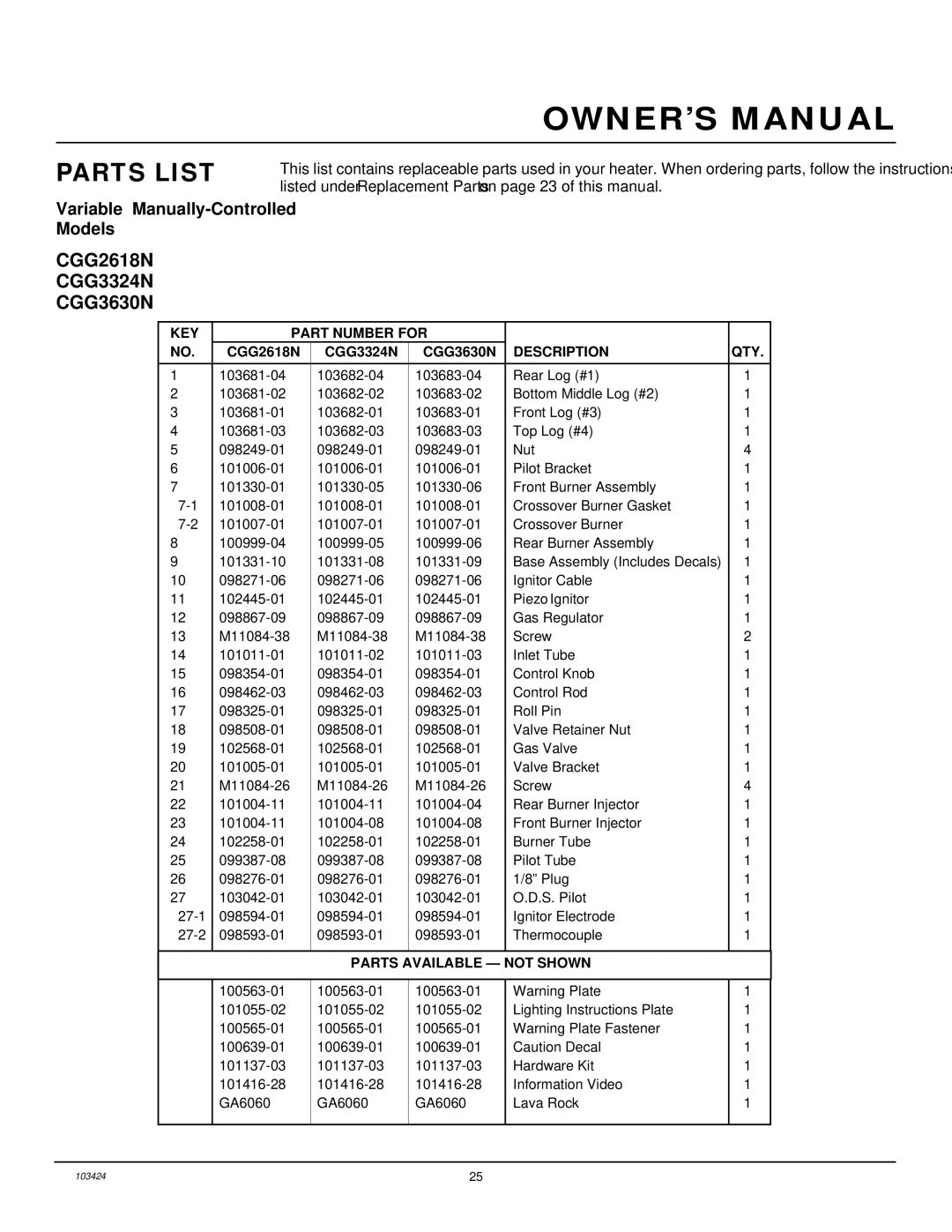

CGG2618N, CGG3324N(T), CGG3630N specifications

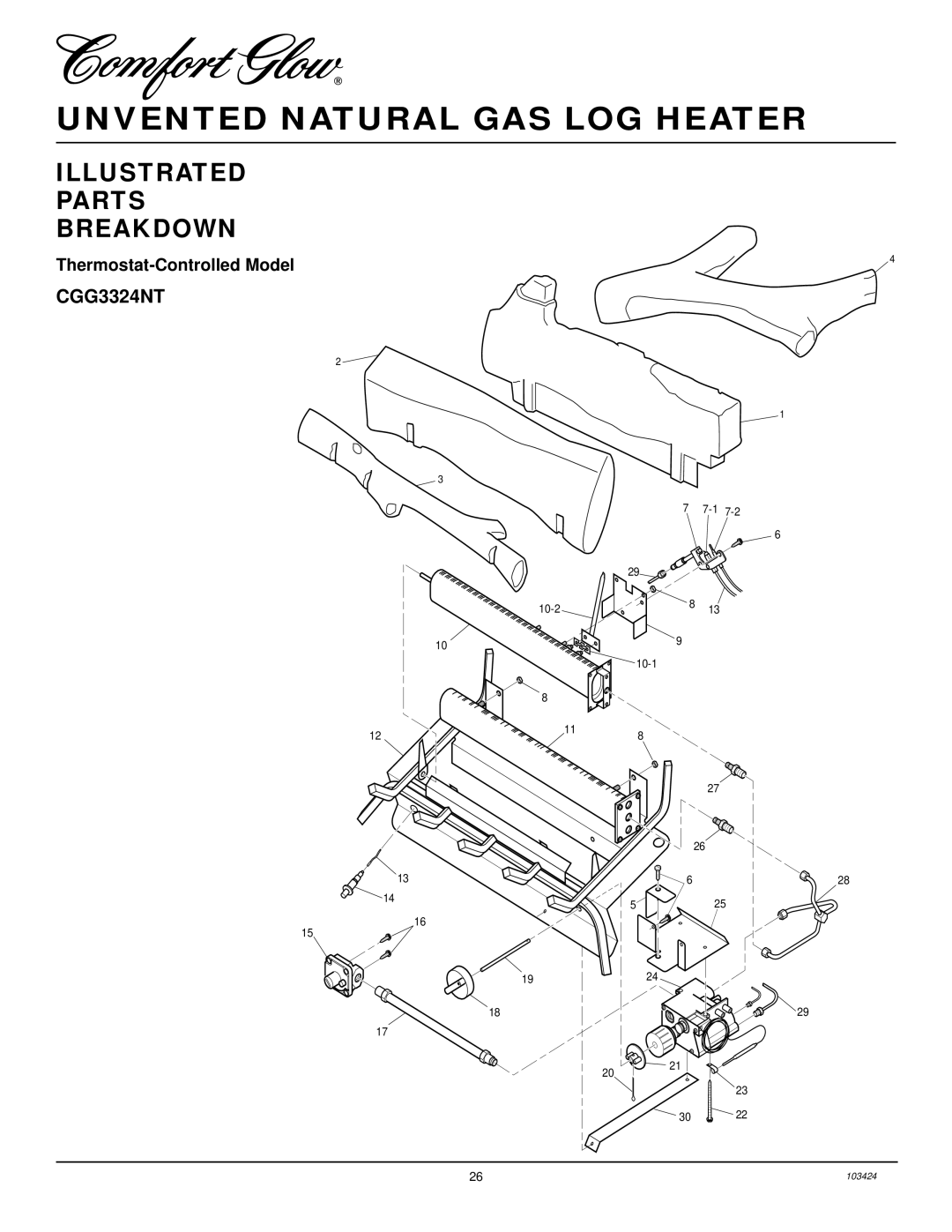

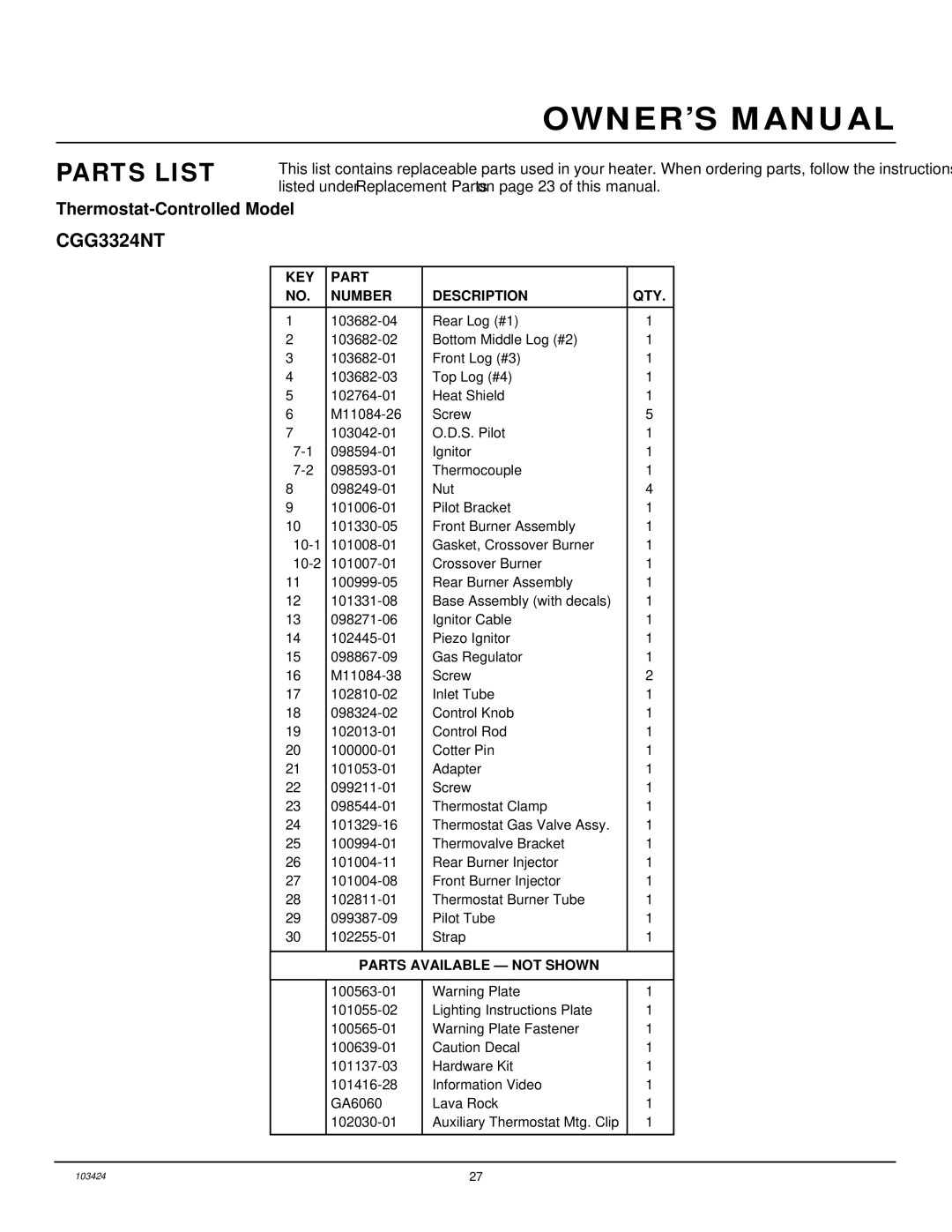

Desa CGG3324N(T), CGG3630N, and CGG2618N are three notable models in the realm of commercial and residential gas heating solutions, each bringing unique characteristics and technologies to meet diverse user needs.The Desa CGG3324N(T) is a powerful option designed for larger spaces. One of its main features is its ability to provide a robust heating output of up to 33,000 BTUs, making it ideal for environments that require consistent warmth during colder months. This model is equipped with an adjustable thermostat, allowing users to set their desired temperature for maximum comfort.

Innovatively, the CGG3324N(T) employs a radiant heat technology that warms objects within the room rather than just the air. This results in a more efficient distribution of warmth and reduced energy costs. Additionally, the model is built with safety in mind, featuring an automatic shut-off valve that activates in case of irregular operation.

Moving on to the Desa CGG3630N, this model is renowned for its oversized heating capacity, reaching up to 36,000 BTUs. It is particularly suited for commercial applications or larger homes. One standout characteristic of the CGG3630N is its dual fuel capability, which allows it to operate using both natural gas and propane. This versatility makes it an appealing choice for users looking to transition between fuel sources based on availability and pricing.

The advanced technology in the CGG3630N includes a multi-burner system that enhances its efficiency by uniformly distributing heat across the space. Furthermore, its contemporary design blends seamlessly with various interior aesthetics, making it a stylish addition to any environment.

Lastly, the Desa CGG2618N is an efficient compact model with a heating capacity of 26,000 BTUs. This model is perfect for both residential and smaller commercial spaces. Its key feature includes an electronic ignition system that makes startup effortless and reliable, reducing the hassle often associated with traditional igniters.

What sets the CGG2618N apart is its user-friendly interface and ease of installation, allowing users to set it up without professional help in many cases. It also boasts a sleek design that requires minimal space while still delivering substantial heating power.

In summary, the Desa CGG3324N(T), CGG3630N, and CGG2618N each provide unique features and technologies tailored to various heating needs. With an emphasis on efficiency, safety, and user engagement, these models stand out in the competitive landscape of gas heating solutions.