HSU 45, HSU 75 specifications

Enerco HSU 75 and HSU 45 are standout models in the realm of portable heating solutions, designed for efficiency and convenience. These units serve a range of applications, from construction sites to workshops, and even for personal use in outdoor settings. With their robust engineering and advanced features, they are ideal for anyone needing reliable warmth in cold conditions.One of the main features of the Enerco HSU series is their impressive heating capacity. The HSU 75 offers a maximum output of 75,000 BTU, making it suitable for larger spaces, while the HSU 45 delivers 45,000 BTU, perfect for smaller areas. This flexibility allows users to choose the right model based on their specific heating needs.

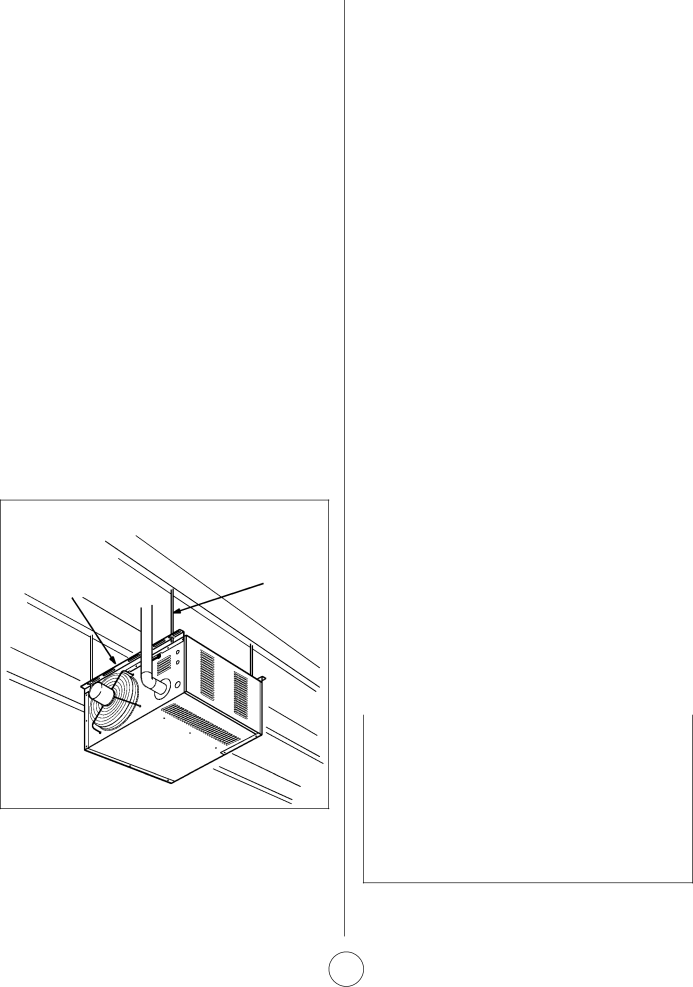

Both models utilize a forced air heating system, which efficiently circulates warmth throughout the space. This technology ensures rapid heating, allowing for immediate relief from the cold, an essential feature in situations where time is of the essence.

Durability is another key characteristic of the HSU series. Constructed with heavy-duty materials, these units are built to withstand the rigors of demanding environments. The robust design makes them suitable for outdoor use, capable of enduring tough weather conditions without compromising performance.

Safety is paramount with Enerco heaters, and both the HSU 75 and HSU 45 come equipped with safety features such as automatic shut-off sensors and flame failure devices. These innovations give users peace of mind, knowing that the unit will operate safely even in unpredictable environments.

Portable design is a hallmark of these heaters, featuring built-in handles and a lightweight structure. This makes it easy for users to transport the units from one location to another, enhancing their versatility in use.

Finally, both models are compatible with various fuel sources, allowing for flexibility based on user preference and availability. Whether using propane or natural gas, users can enjoy efficient heating tailored to their requirements.

In conclusion, the Enerco HSU 75 and HSU 45 represent a perfect blend of power, safety, and portability. Their advanced features and durable build make them ideal companions for anyone needing dependable heat in diverse scenarios. With these units, warmth is always within reach, ensuring comfort regardless of the harshness of the outdoor conditions.