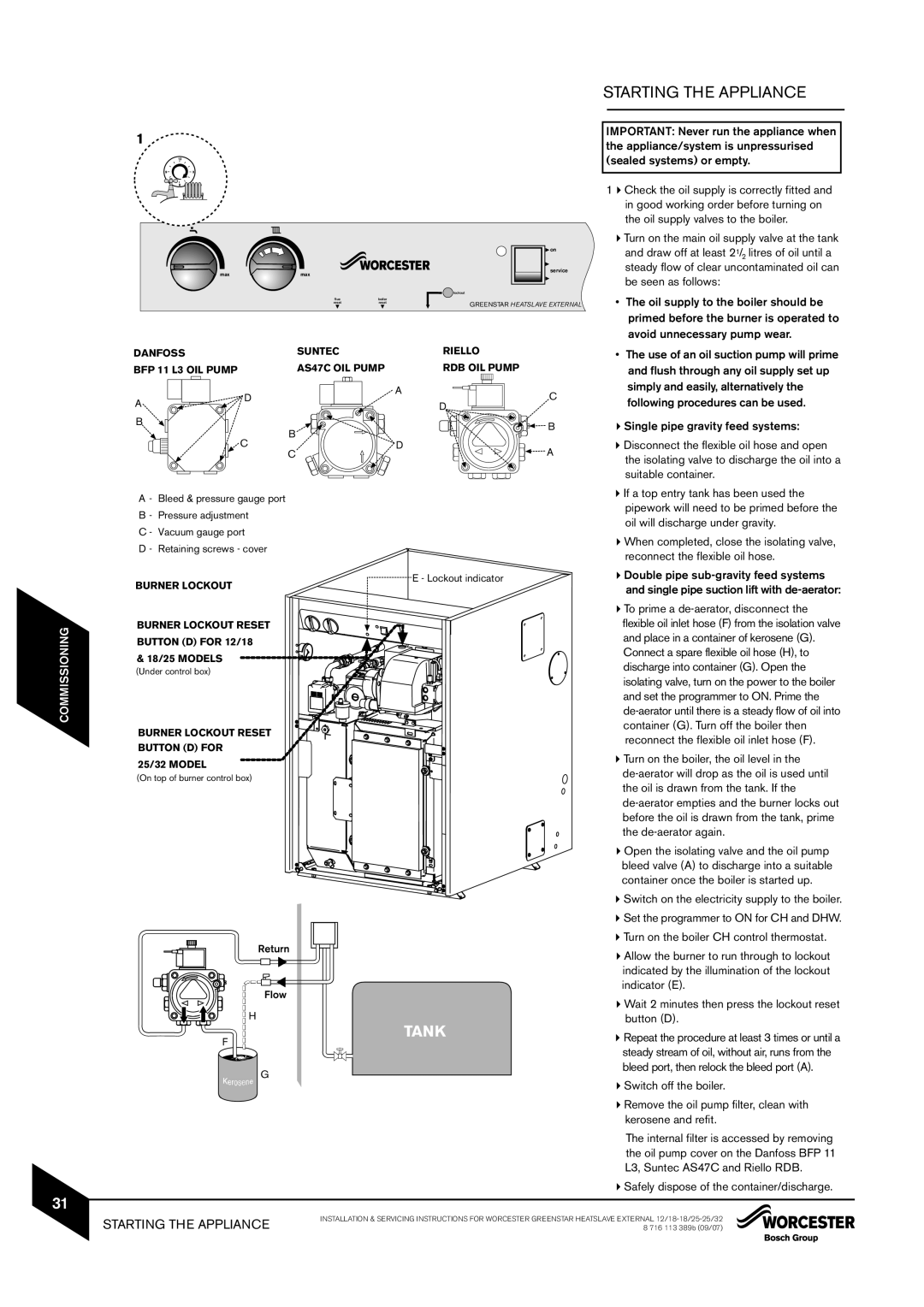

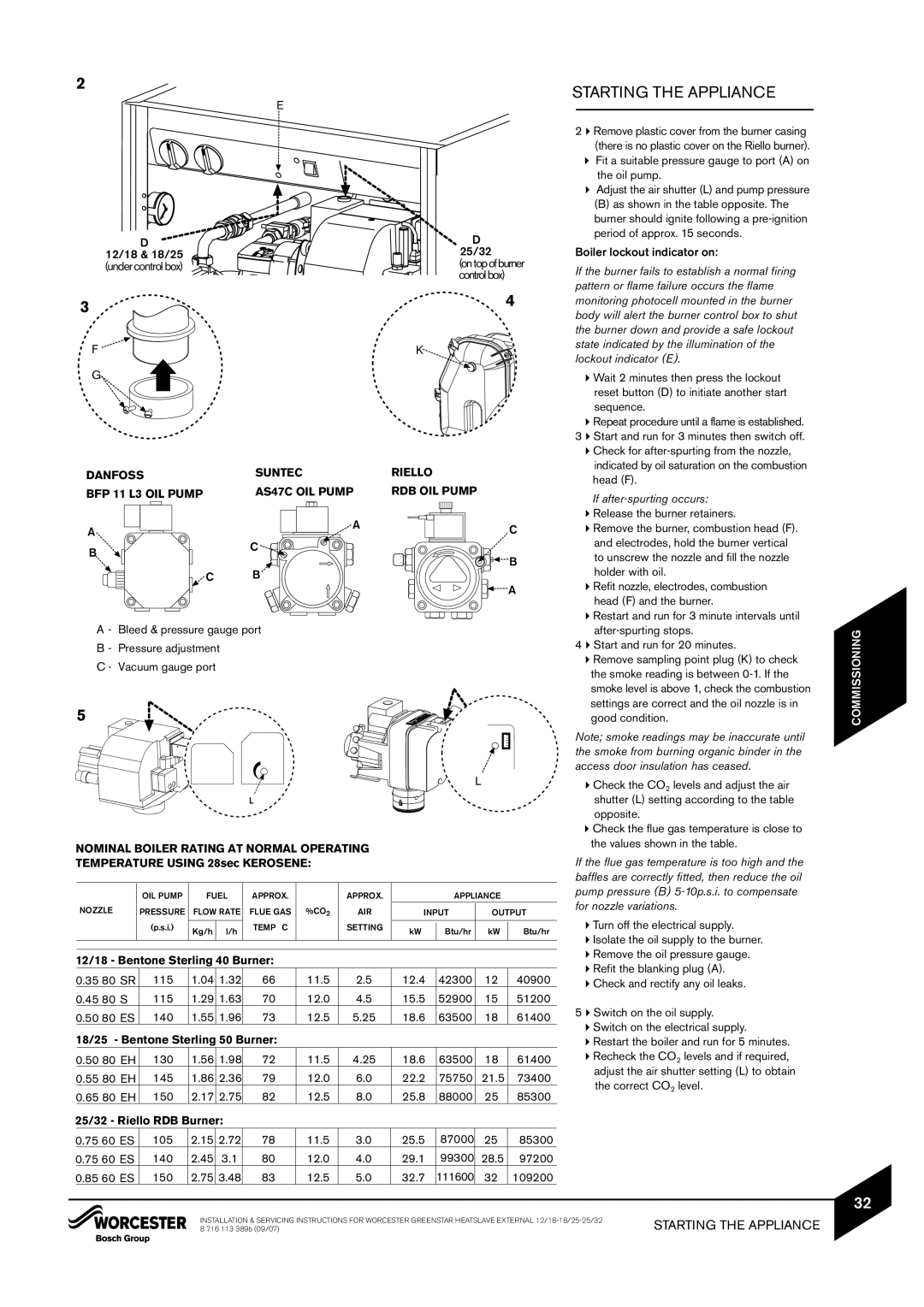

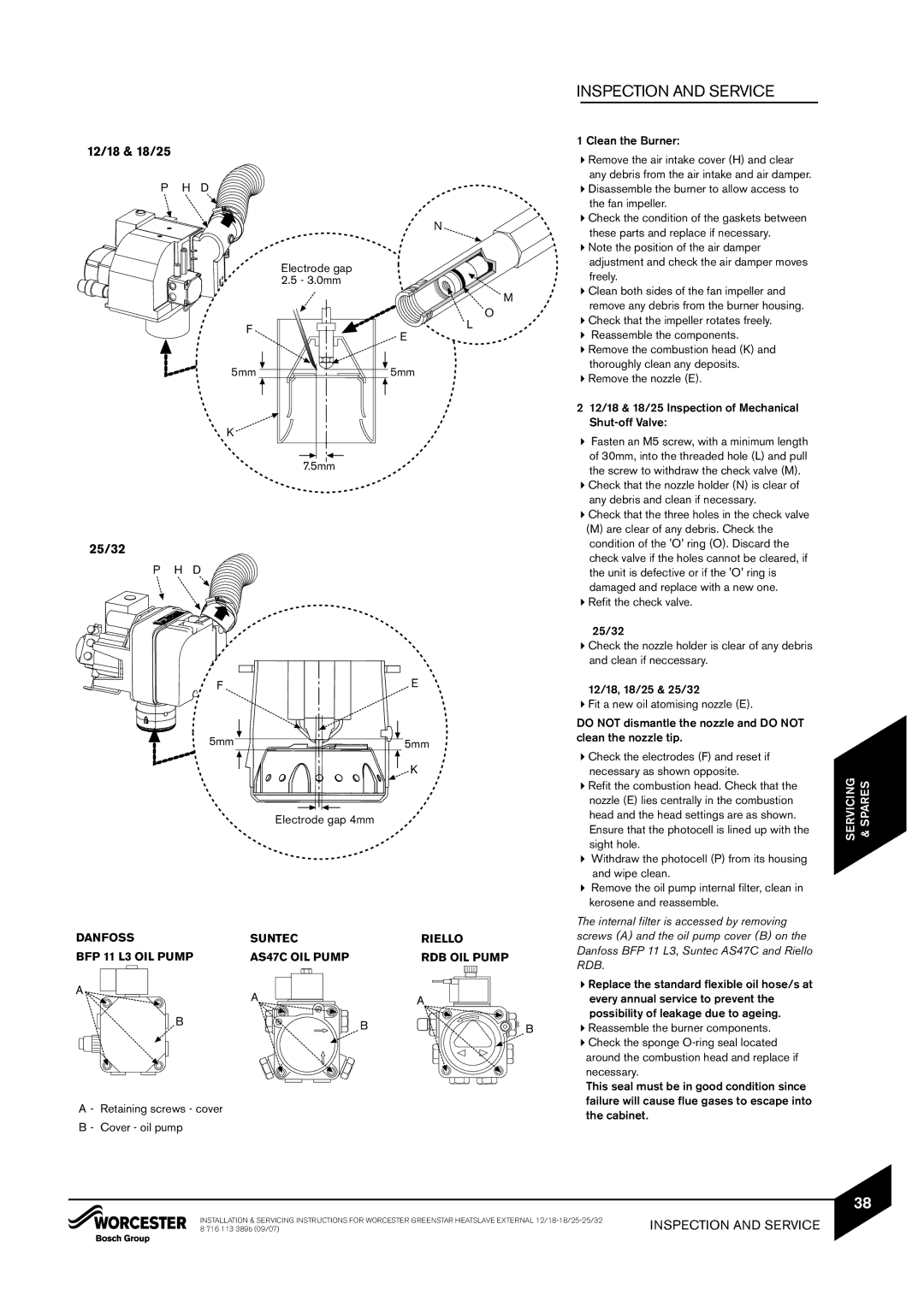

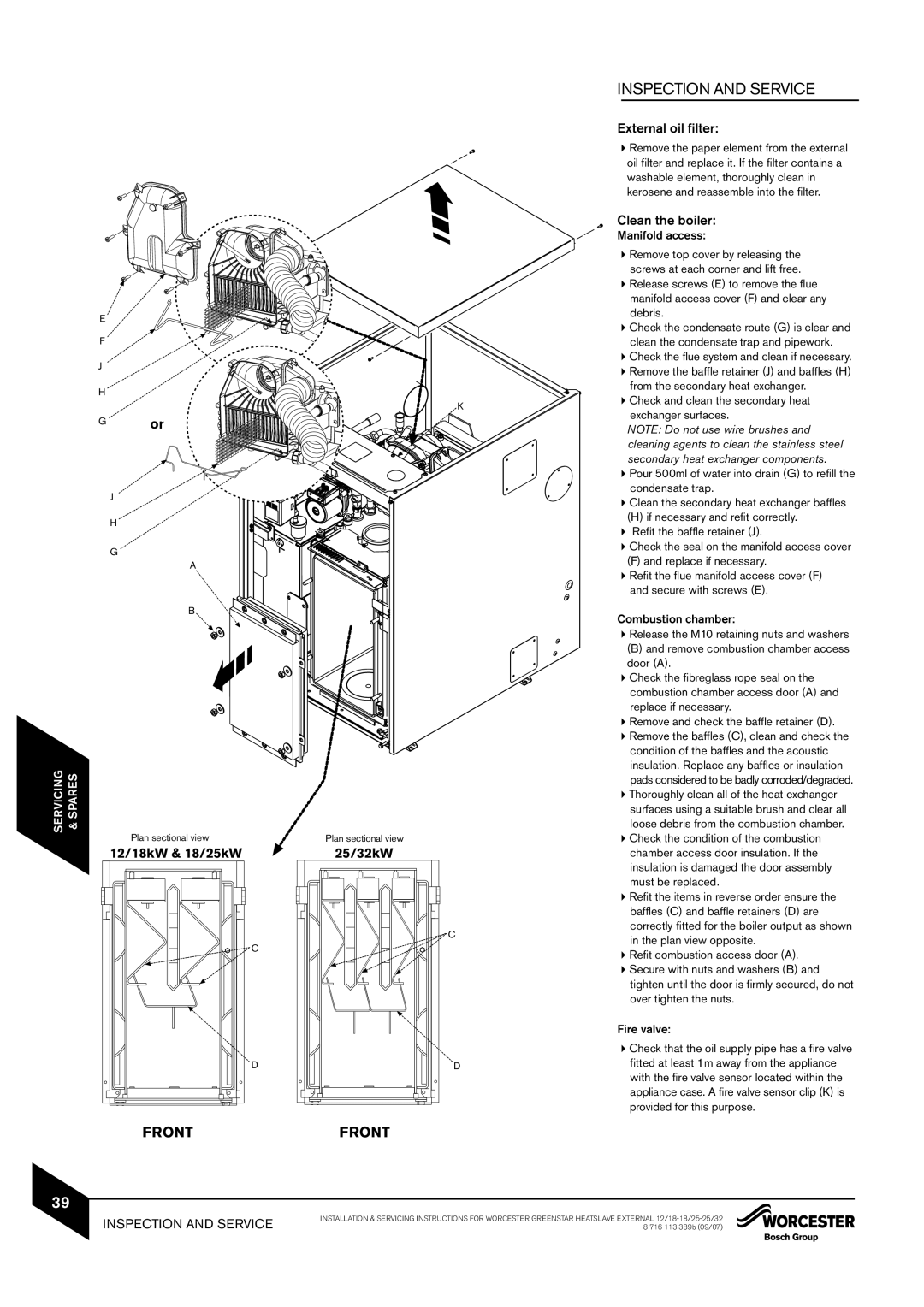

25/32kW, 12/18, 18/25 specifications

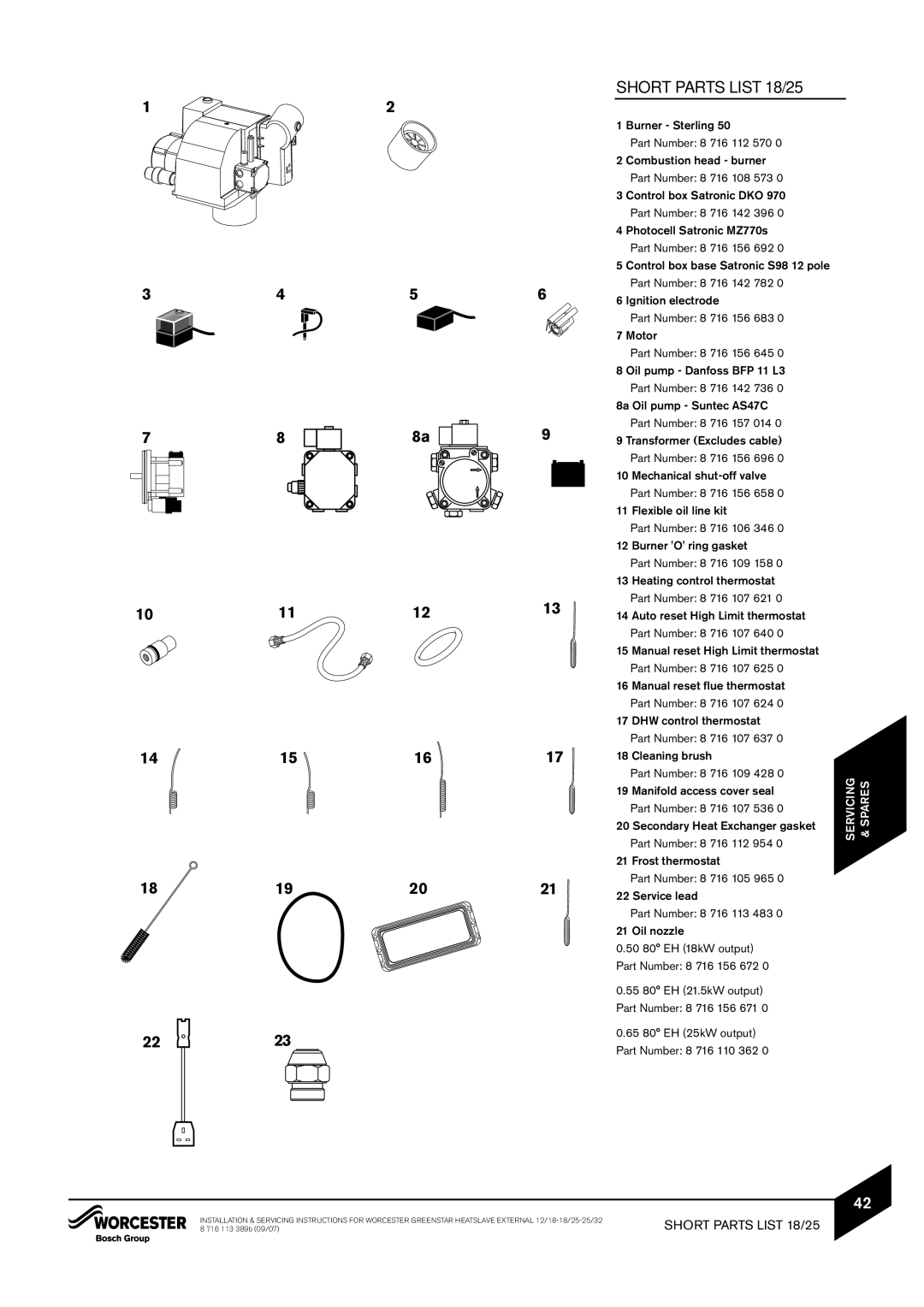

Bosch Appliances has carved out a reputation for engineering high-performance heating solutions, particularly with their range of heating systems including the 18/25, 12/18, and 25/32 kW models. These systems are designed to meet the diverse needs of residential and commercial spaces while maintaining energy efficiency and sustainability.The Bosch 18/25 kW model excels in providing an optimal heating solution for medium to large residential properties. It is equipped with a highly efficient condensing boiler that extracts additional heat from flue gases, achieving significant energy savings. The built-in, user-friendly interface allows for easy programming and monitoring, which maximizes user convenience.

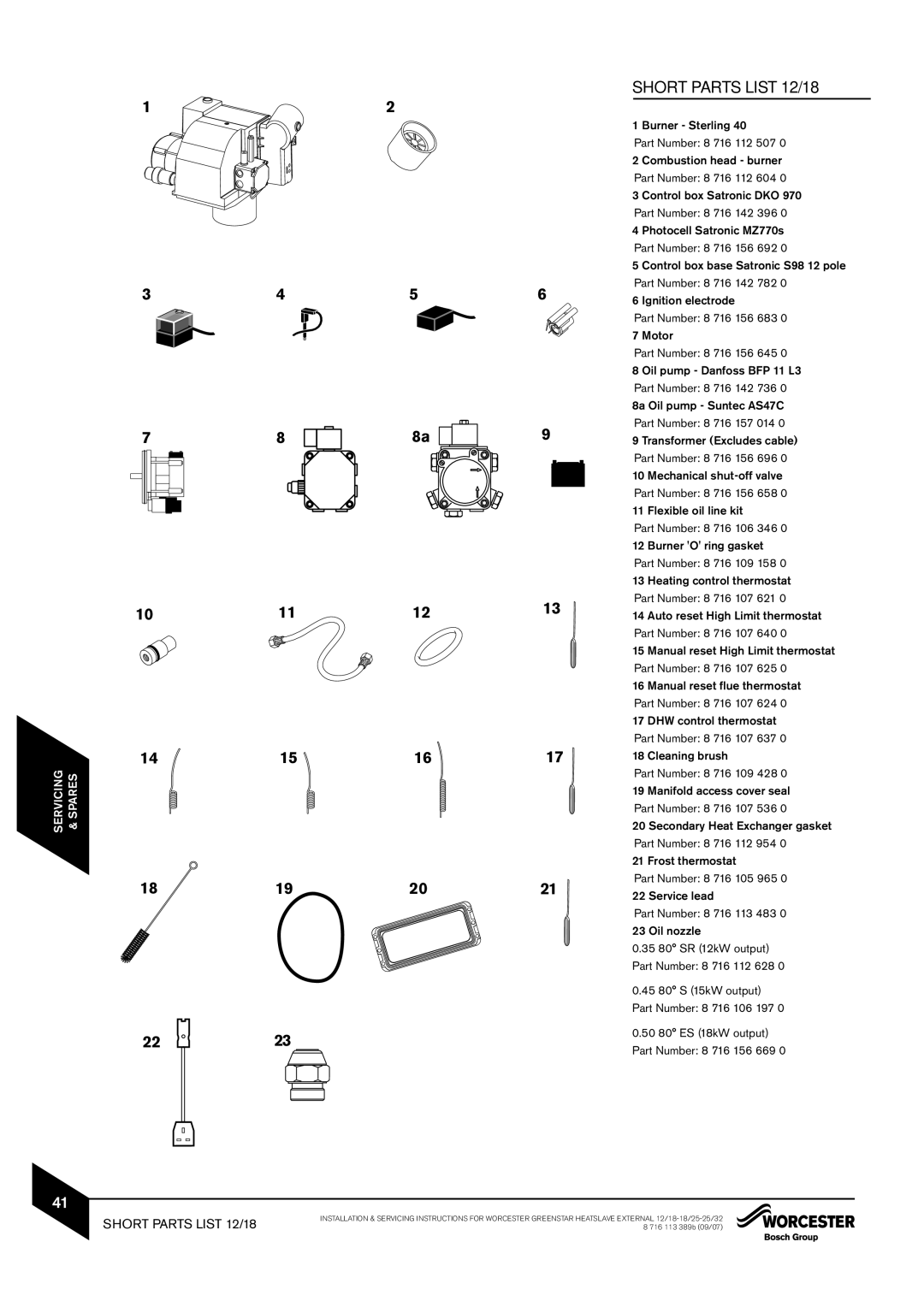

The 12/18 kW model provides a versatile opportunity for smaller homes or apartments. Its compact design ensures that it fits seamlessly into tighter spaces without sacrificing performance. The unit operates quietly, making it an excellent choice for residential areas where noise can be a concern. Additionally, it features the latest modulation technology, optimizing energy usage and maintaining consistent temperatures.

Finally, the 25/32 kW model is ideal for larger installations, offering robust performance even in high-demand scenarios. This model benefits from advanced heating management systems that enable intelligent control of heating zones, ensuring efficiency and comfort throughout the property. With its enhanced energy rating, the 25/32 kW model significantly reduces the carbon footprint, aligning with modern sustainability goals.

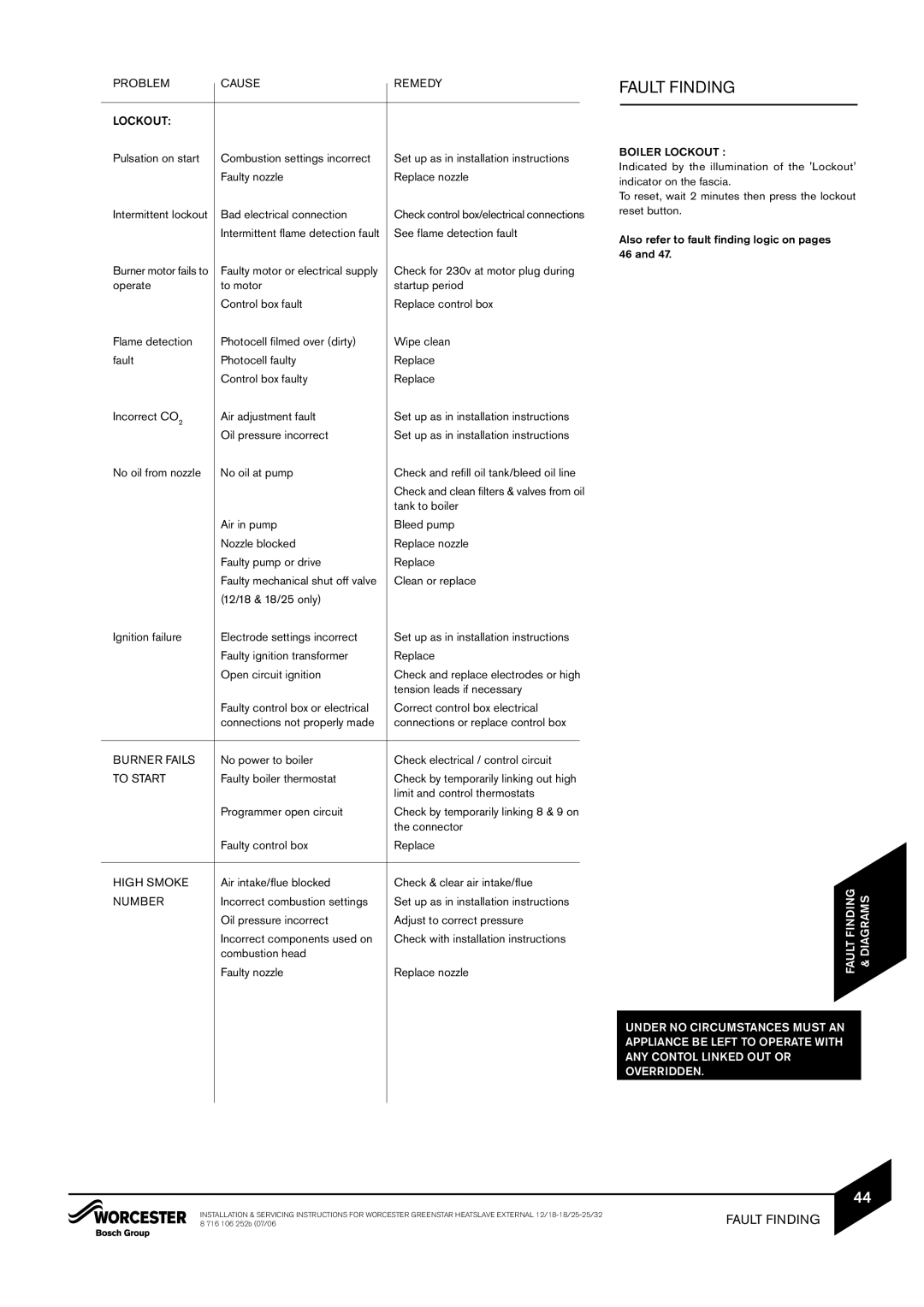

Across the board, Bosch Appliances integrates advanced technologies such as intelligent diagnostics, smart home compatibility, and eco-friendly materials. All models are constructed with durability in mind, featuring corrosion-resistant heat exchangers and high-quality components designed for longevity.

The customer-focused features, including comprehensive warranty packages and responsive customer service, further exemplify Bosch's commitment to quality. Overall, Bosch Appliances 18/25, 12/18, and 25/32 kW heating systems stand out for their innovative technology, efficient performance, and reliability, making them an excellent choice for those looking to upgrade their heating solutions.